A low head high flow reversible tubular flow pump with asymmetrical sx blades

A high-flow, asymmetric technology, applied to the components, pumps, pump devices, etc. of the pumping device for elastic fluid, can solve the problems of complex structure, large mechanical loss of the unit, large hydraulic loss of the flow channel, etc. The available range, the protection of the ecological environment, and the effect of saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

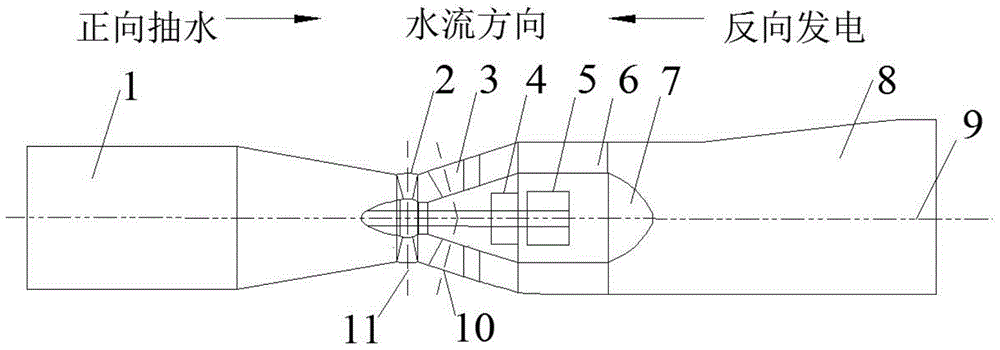

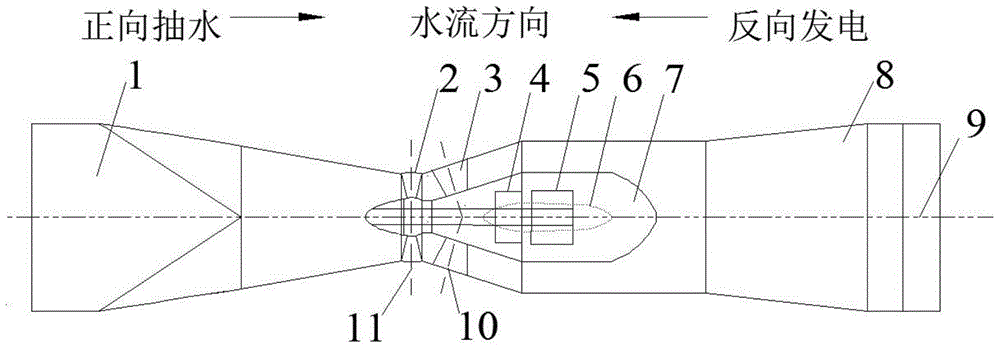

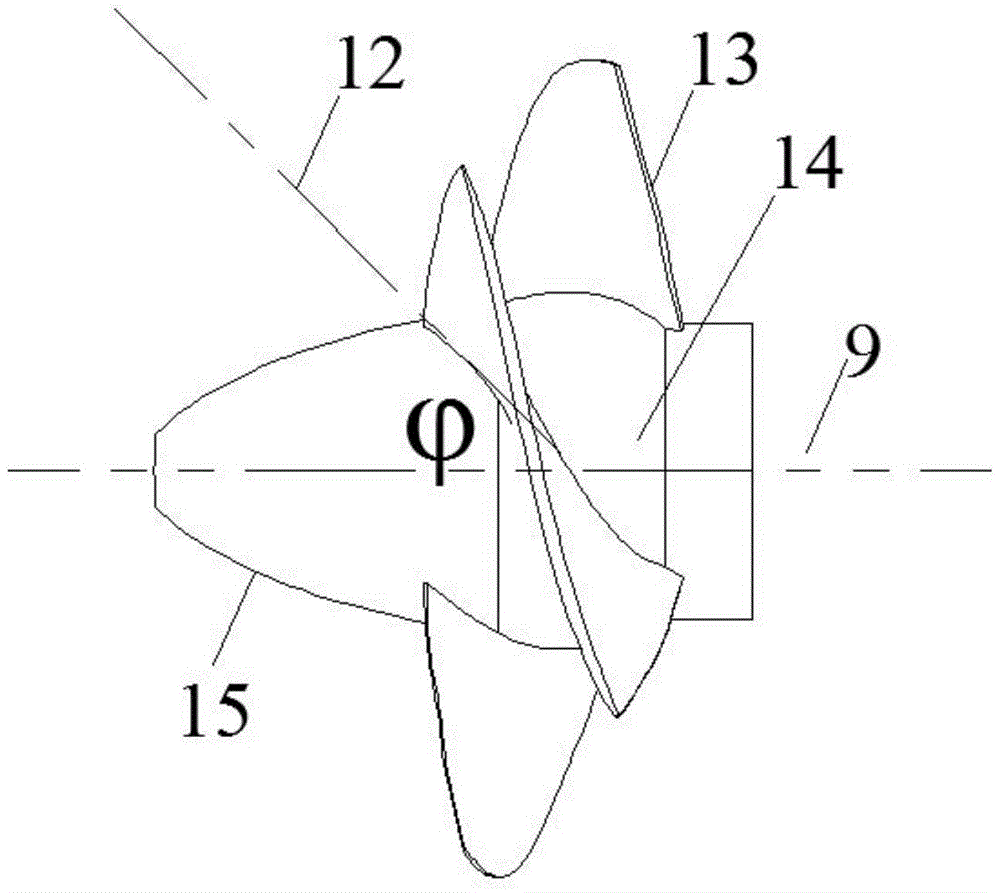

[0024] combine figure 1 and figure 2, the present invention proposes a low-lift high-flow reversible through-flow pump with asymmetric SX blades, which includes a forward water inlet channel (1), a runner (2), guide vanes (3), a gear box ( 4), reversible motor (5), bulb body (6), casing (7) and reverse water inlet channel (8), wherein: the forward water inlet channel (1) is set on the runner (2) The positive water inlet end, the guide vane (3) is set on the neck of the bulb body (6), the reversible motor (5) and the gear box (4) are placed in the bulb body (6), and the runner (2) passes through The main shaft, the gear box (4), and the reversible motor (5) are set coaxially in sequence, the sleeve (7) is nested and connected with the bulb body (6), and the positive water outlet end of the bulb body (6) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com