Method for implementing oil well deep part selective water plugging by utilizing waste polystyrene foam plastic

A technology of discarding polystyrene and foam plastics, which is applied in wellbore/well parts, chemical instruments and methods, earthwork drilling and production, etc. It can solve the problems of selective water shutoff in the deep part of the oil layer and the inability to reach the deep part of the oil layer, etc., and achieve cost The effect of low, strong selectivity and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation and evaluation of embodiment 1 blocking agent solution

[0032] Add the recovered waste polyethylene foam plastics to the mixed solvents in schemes k to n in Table 1, heat to 40°C to 60°C, and stir to dissolve. Experiments show that waste polyethylene foam can be quickly dissolved in the mixed solvents in Table 1, and no precipitation occurs after cooling to room temperature. Can improve production time rate.

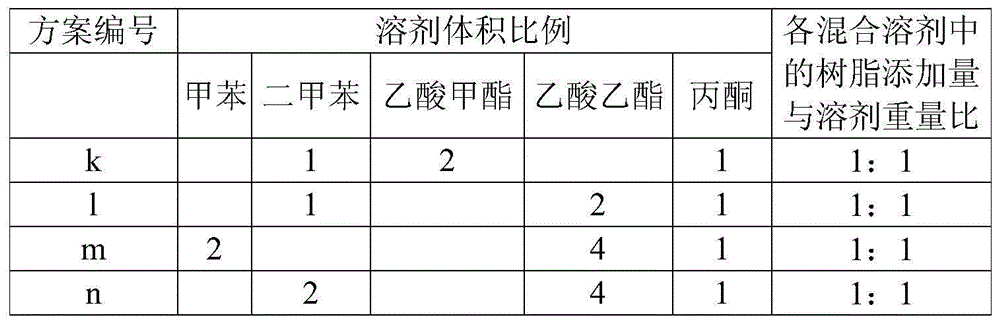

[0033] Table 1. The distribution ratio of each component of the mixed solvent

[0034]

Embodiment 2

[0036] A well in Huanxi Oilfield, 1063.40m-1111.80m, 23m / 10 layers, steam injection for the 15th time. The average permeability is 1329.8mD (millidarcy), the daily liquid production is 25.8 cubic meters, the daily oil production is 0.5 tons, and the water content is 98%. The oil well has high water cut, so it is decided to adopt selective water shutoff in the deep part of the oil layer.

[0037] The implementation steps are as follows:

[0038] 1. Recycle waste polystyrene foam, remove surface debris, and reserve;

[0039] 2. Preparation of plugging agent solution: The organic solvent is a mixed solution obtained by mixing xylene, ethyl acetate and acetone according to the volume ratio of 2:4:1, heated in a water bath to 50°C, and 10 parts by weight of the above spare waste polyethylene foam Add the plastic to 10 parts by weight of the organic solvent, and stir while adding, until all the waste polyethylene foam plastics for use are dissolved, then add 100 parts by weight of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com