Construction method of large-scale parallel flexible lower-cord combined trusses

A technology of flexible lower chord and combined truss, which is applied to truss structures, girders, truss beams, etc., can solve the problems of difficult active tensioning of flexible lower chords, unreliable initial bearing capacity of large-diameter flexible lower chords, etc., achieving high construction efficiency and ensuring Stability, force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

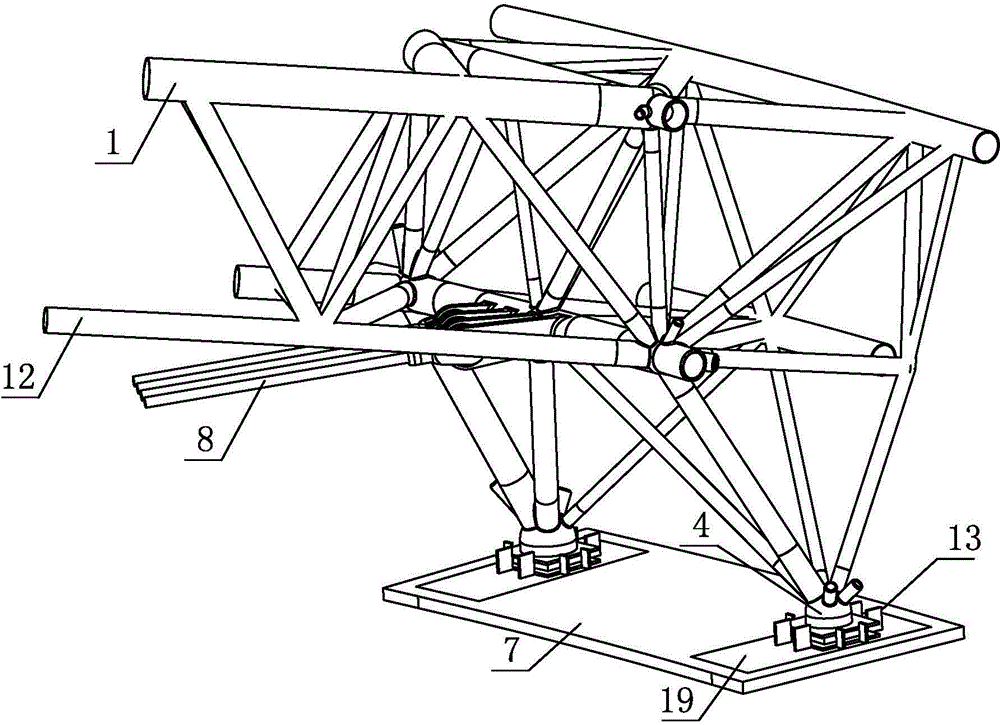

[0025] The preferred examples of the present invention will be described in further detail in conjunction with the accompanying drawings 1-6.

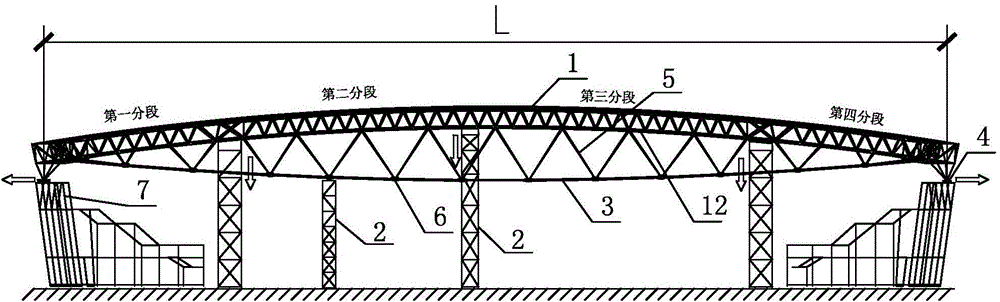

[0026] A preferred example of the present invention is a super-large parallel flexible lower chord composite truss with a span of 232m in a certain stadium roof structure. The upper chord layer 1 of the truss is a trapezoidal cross-section, and the web 5 is a double K cross type.

[0027] The sagittal height of the upper chord layer 1 of the truss is only 8.2m, which is 1 / 28.3 of the span, but the structural span L reaches 232m. The structure will generate a huge horizontal thrust of the support 4 under its own weight. The structural design requires the use of flexible lower chord during construction. 3 Establish the initial pre-tension to balance and reduce the effect of the structure on the lower concrete structure 7.

[0028] The lower chord 3 of the truss adopts four parallel-connected large-diameter (200mm) equal-strength alloy st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com