Cationic modified dyeing process for cellulose fiber

A cationic modification, cellulose fiber technology, applied in the field of textile dyeing, can solve the problems of not being suitable for large-scale production, high chroma of dyeing residue, difficult to treat wastewater, etc. Penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

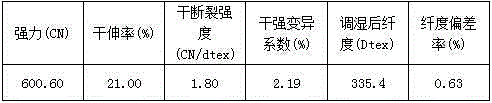

Embodiment 1

[0078] Cellulose fiber dyeing process:

[0079] The cationic modification dyeing process of cellulose fiber comprises the following process steps:

[0080] A. Cellulose fiber modification treatment

[0081] Put the cellulose fiber into the container, add water to the container, and then modify the cellulose fiber with two cationic modifiers, the small molecule quaternary ammonium salt cationic modifier and the high molecular quaternary ammonium salt cationic modifier After the modification treatment is completed, modified cellulose fibers are obtained; the small molecular quaternary ammonium salt cationic modifier is an epoxy quaternary ammonium salt compound, and the high molecular quaternary ammonium salt cationic modifier is cationic starch;

[0082] B. Washing treatment

[0083] Washing the modified cellulose fibers obtained through the modification treatment in step A;

[0084] C. Dyeing

[0085] Putting the modified cellulose fibers washed with water in step B into a...

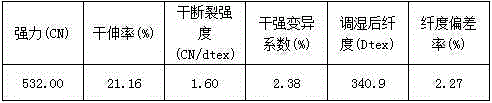

Embodiment 2

[0090] Cellulose fiber dyeing process:

[0091] The cationic modification dyeing process of cellulose fiber comprises the following process steps:

[0092] A. Cellulose fiber modification treatment

[0093] Put the cellulose fiber into the container, add water to the container, and then modify the cellulose fiber with two cationic modifiers, the small molecule quaternary ammonium salt cationic modifier and the high molecular quaternary ammonium salt cationic modifier After the modification treatment is completed, modified cellulose fibers are obtained; the small molecular quaternary ammonium salt cationic modifier is an epoxy quaternary ammonium salt compound, and the high molecular quaternary ammonium salt cationic modifier is cationic starch;

[0094] B. Washing treatment

[0095] Washing the modified cellulose fibers obtained through the modification treatment in step A;

[0096] C. Dyeing

[0097] Putting the modified cellulose fibers washed with water in step B into a d...

Embodiment 3

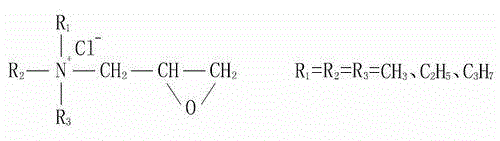

[0103] The small molecule quaternary ammonium salt cationic modifier of the present invention is an epoxy quaternary ammonium salt compound;

[0104] The polymer quaternary ammonium salt cationic modifier of the present invention is cationic starch.

[0105] Epoxy quaternary ammonium compound:

[0106]

[0107] Cationic starch modifier:

[0108]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com