High-precision energy-saving galvanized air knife

An energy-saving and high-precision technology, applied in hot-dip plating process, metal material coating process, coating and other directions, it can solve the problems of difficult to accurately control the amount of thin coating, uneven thickness of the plate surface, and poor air pressure stability. , to achieve the effect of reducing uneven pressure distribution, uniform thickness of plate surface coating, and increasing pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

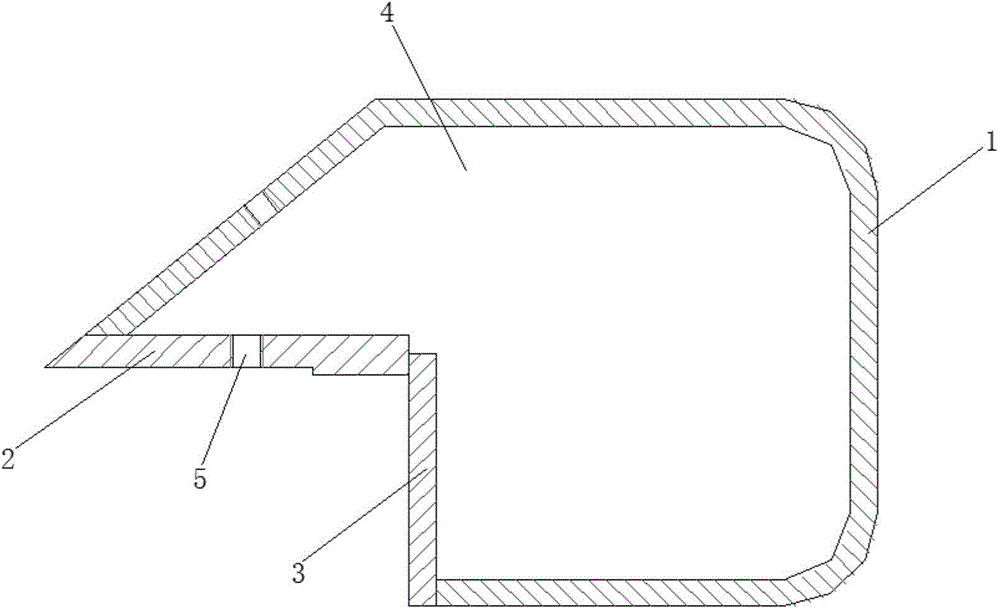

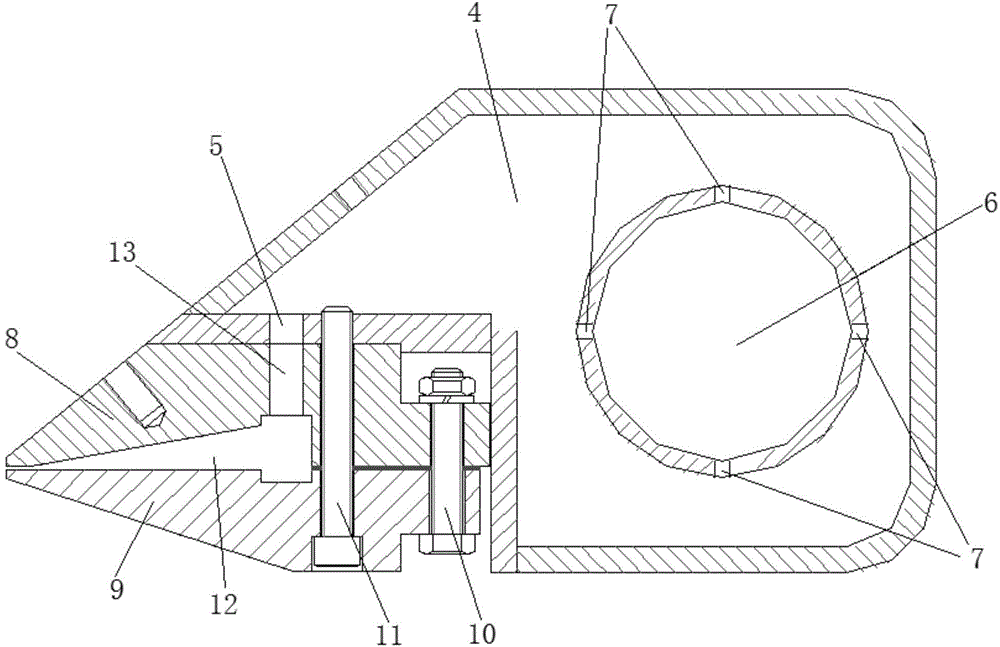

[0022] Such as figure 1 As shown, the first cavity 4 of the air knife of the present invention is surrounded by the first cavity plate 1, the second cavity plate 2 and the third cavity plate 3, and the second cavity plate 2 is provided with a vent hole 5. Such as figure 2 As shown, a circular second cavity 6 is provided in the first cavity 4, and the second cavity 6 is not limited to a circular shape, but a circular shape is better. The second cavity 6 is provided with an exhaust flow distribution hole 7 every 90°, four rows are arranged in total, the air flow enters the second cavity 6 and enters the first cavity 4 along the air flow distribution hole 7 .

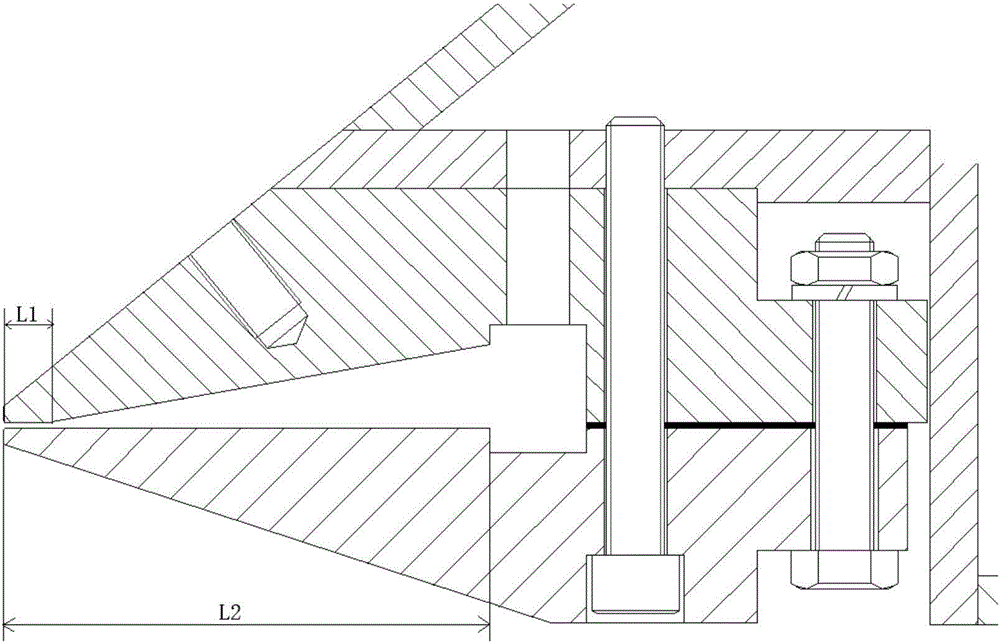

[0023] An upper blade 8 and a lower blade 9 are arranged below the cavity plate 2, and the upper blade 8 and the lower blade 9 are connected together by bolts 10, and the connected upper blade 8 and the lower blade 9 are fixed on the cavity plate by screws 11 Two 2 on. A lip cavity 12 is formed between the end surfaces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com