Chemical and physical crosslinking based dual-network cellulose gel system material

A technology of cellulose gel and cellulose hydrogel, which is applied in the field of cellulose materials and double network cellulose gel materials, can solve the problems of low elongation at break, poor toughness of hydrogel, poor mechanical properties, etc. , to achieve the effect of excellent product performance, low cost and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

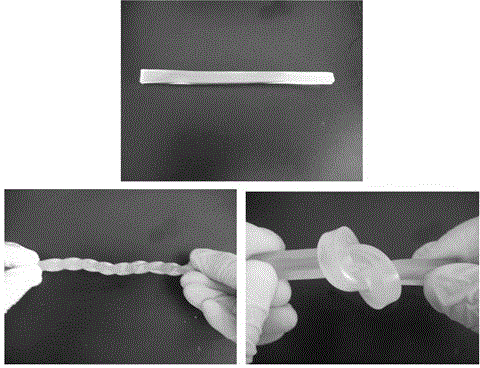

[0038] Prepare 6-8 wt% NaOH, 4-20 wt% urea and the rest of water as a solvent, add cotton linter pulp with a degree of polymerization of 300, stir and freeze overnight below freezing point, and obtain a concentration of 6 wt% after thawing Cellulose solution. at 25 o At C, add epichlorohydrin according to the molar ratio of cross-linking agent to cellulose is 0.1:1, stir evenly, place in the mold for 1 hour to obtain a partially chemically cross-linked cellulose gel, and then place the gel in distilled water Continue physical cross-linking after 30 minutes, and finally wash to neutral to obtain a transparent double network cellulose hydrogel. The double-network cellulose hydrogel can be stretched, bent, folded, and twisted without breaking, and has very good toughness.

Embodiment 2

[0046] Prepare 6 ~ 10 wt% NaOH, 0.1 ~ 10 wt% thiourea and the rest of water as a solvent, add cotton linter pulp with a polymerization degree of 500, stir and freeze overnight below freezing point, and obtain a concentration of 6 wt% after thawing of cellulose solution. at 15 o Under C, add epichlorohydrin according to the molar ratio of cross-linking agent to cellulose is 0.5:1, stir evenly, place in the mold for 12 hours to obtain a partially chemically cross-linked cellulose gel, and then place the gel in distilled water The physical cross-linking was continued for 1 h, and finally washed to neutral to obtain a transparent double network cellulose hydrogel. The double-network cellulose hydrogel can be stretched, bent, folded, and twisted without breaking, and has very good toughness. Such as figure 1 shown.

Embodiment 3

[0048] Prepare 3.8 ~ 6.3 wt% LiOH, 4 ~ 20 wt% urea and the rest of water as a solvent, add bagasse pulp with a polymerization degree of 400, stir and freeze overnight below freezing point, and obtain a concentration of 7 wt% after thawing Cellulose solution. at 10 o C, according to the molar ratio of cross-linking agent and cellulose is 1:1, add epoxy chlorobutane, stir evenly, place in the mold for 12 hours to obtain a partially chemically cross-linked cellulose gel, and then place the gel in The physical crosslinking was continued in 50wt% ethanol for 2h, and finally washed with water until neutral to obtain a transparent double network cellulose hydrogel. The double-network cellulose hydrogel can be stretched, bent, folded, and twisted without breaking, and has very good toughness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com