Sea urchin-shaped aluminum oxyhydroxide ball and preparation method thereof

A technology of aluminum oxyhydroxide and sea urchin shape, which is applied in the field of preparation of aluminum oxyhydroxide functional materials, and achieves the effects of wide application prospects, high surface area, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1.1 Add 0.2mL of deionized water to 20mL of absolute ethanol, add 0.2μL of thioglycolic acid dropwise to the mixed solution of ethanol and water under stirring conditions, and finally stir fully at room temperature to obtain a uniform and transparent The solution;

[0029] 1.2 Add 0.058 g of aluminum isopropoxide to the solution prepared in Example 1.1, and stir fully at room temperature to obtain a uniform white emulsion;

[0030] 1.3 The emulsion obtained in Example 1.2 was transferred to a reaction kettle, and reacted at 220°C for 20 hours. After the reaction was completed, aluminum oxyhydroxide microspheres were obtained by centrifugal separation and washing.

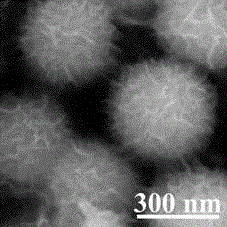

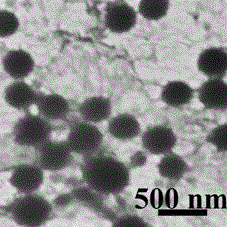

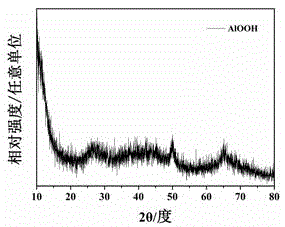

[0031] figure 1 Scanning electron micrographs of the obtained samples, figure 2 It is a transmission electron microscope photo of the obtained sample. As can be seen from the figure, the product is spherical, with a fluffy structure on the surface of the ball, similar to the shape of a sea urchin, and the ...

Embodiment 2

[0033] 2.1 Add 0.2 mL of deionized water to 20 mL of absolute ethanol, add 0.2 μL of thioglycolic acid dropwise to the mixed solution of ethanol and water under stirring conditions, and stir well to obtain a uniform and transparent solution;

[0034] 2.2 Add 0.058 g of aluminum isopropoxide to the solution prepared in Example 2.1, and stir fully at room temperature to obtain a uniform white emulsion;

[0035] 2.3 Transfer the emulsion obtained in Example 2.2 to a reaction kettle, and react at 300°C for 20 hours. After the reaction is completed, aluminum oxyhydroxide microspheres are obtained by centrifugation and washing, with the same appearance as figure 1 , and its particle size is 400-550nm.

Embodiment 3

[0037] 3.1 Add 0.2mL of deionized water to 20mL of absolute ethanol, add 0.2μL of thioglycolic acid dropwise to the mixed solution of ethanol and water under stirring conditions, and finally stir fully at room temperature to obtain a uniform and transparent The solution;

[0038] 3.2 Add 0.248 g of aluminum isopropoxide to the solution prepared in Example 3.1, and stir well at room temperature to obtain a uniform white emulsion;

[0039] 3.3 Transfer the emulsion obtained in Example 3.2 to a reaction kettle, and react at 200°C for 20 hours. After the reaction is completed, obtain pure aluminum oxyhydroxide microspheres with the same morphology as figure 1 , and its particle size is 250-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com