Tower crane with watering function and manufacturing method thereof

A tower crane and functional technology, applied in the direction of load hanging components, cranes, transportation and packaging, can solve the problems of increasing the danger of operators, casualties, and prone to accidents, improving the quality of the construction environment, reducing the work intensity, The effect of reducing the risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

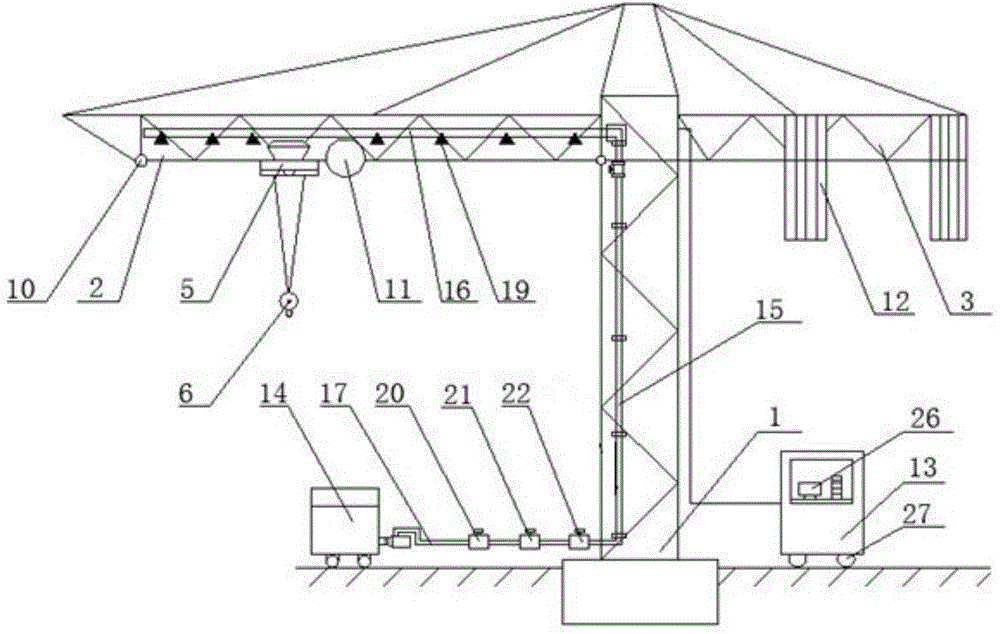

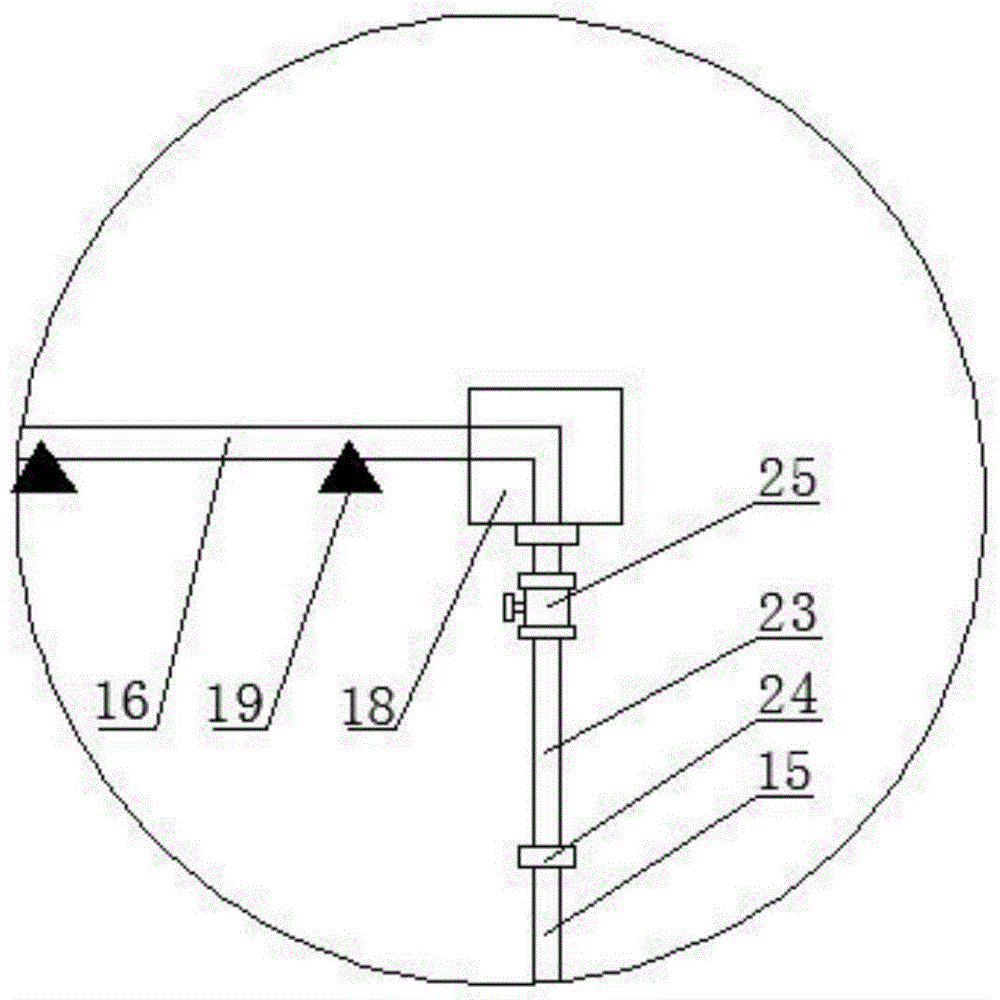

[0021] Example 1: See Figure 1-3 , a tower crane with sprinkler function, comprising a tower hanger 1, a boom 2, a balance arm 3 and a sprinkler 4, the sprinkler 4 is installed on the tower hanger 1, and the two sides of the upper part of the tower hanger 1 are respectively provided with The boom 2 and the balance arm 3, the bottom of the boom 2 is provided with a guide rail 4, the guide rail 4 is provided with a sliding trolley 5, the lower part of the sliding trolley 5 is provided with a hook 6, and the lower end of the hook 6 is provided with a camera 7, The front and rear ends of the sliding trolley 5 are respectively connected with a rope, and the ropes are connected to the reel 11 arranged in the middle of the boom 2 through the guide wheels 10 positioned at the front and rear ends of the boom 2 respectively. A counterweight 12 is respectively provided at the middle part and the tail; the camera 7 is connected to the tower crane control room 13 on the ground, and a disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com