Pipe coiler

A tube-winding and tube-feeding technology, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., can solve the problems of difficulty in ensuring the uniformity of the helical distance of the heat exchange tube, affecting the heat exchange effect, and low work efficiency , to achieve the effect of reducing the risk of scrapping, saving labor costs, and smooth pipe delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

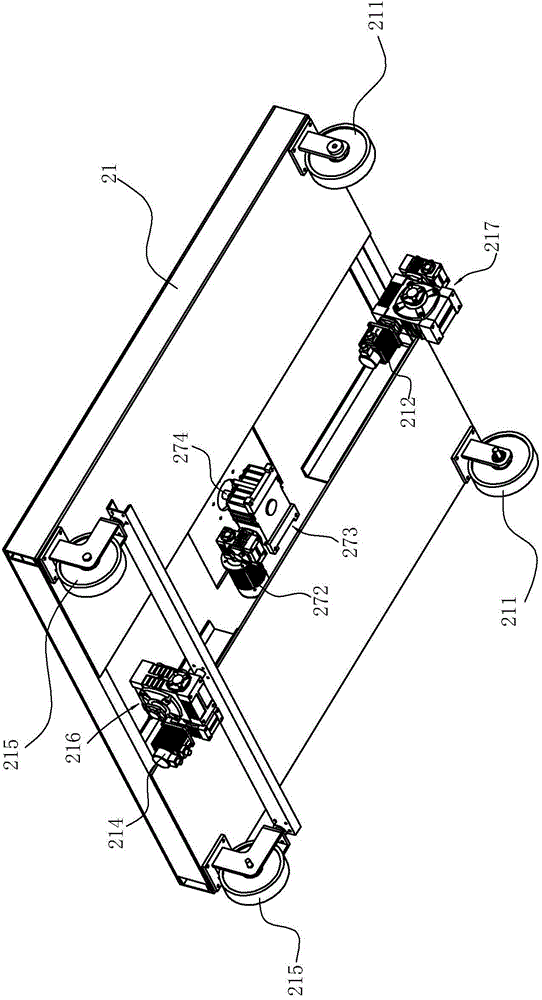

[0046] Such as Figure 1 to Figure 13 As shown, the pipe winding machine includes a pipe unwinding device 2, a pipe feeding device 1, sensors and a control system.

[0047] Wherein, pipe delivery device 1 comprises:

[0048] The tube delivery base 11 is provided with a wheel 111 on the lower surface of the tube delivery base, and the tube delivery base 11 is provided with a guide mechanism 12 . The guide mechanism 12 in this embodiment includes a connecting plate 121 arranged on the pipe feeding base 11, two fixed pulleys 122 are arranged in parallel on the connecting plate 121, and the guide rod arranged on the pipe winding operation platform passes through the two fixed pulleys. between the pulleys.

[0049] In this way, under the cooperation and limiting action of the guide rod 4 and the fixed pulley, the tube delivery base 11 walks alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com