Cloth laying machine

A cloth spreading machine and frame technology, which is applied in the direction of spreading thin soft materials, thin material handling, transportation and packaging, etc. It can solve the problem of inability to arrange cloth spreading devices, poor spreading efficiency, and inability to effectively flatten cloth folds And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

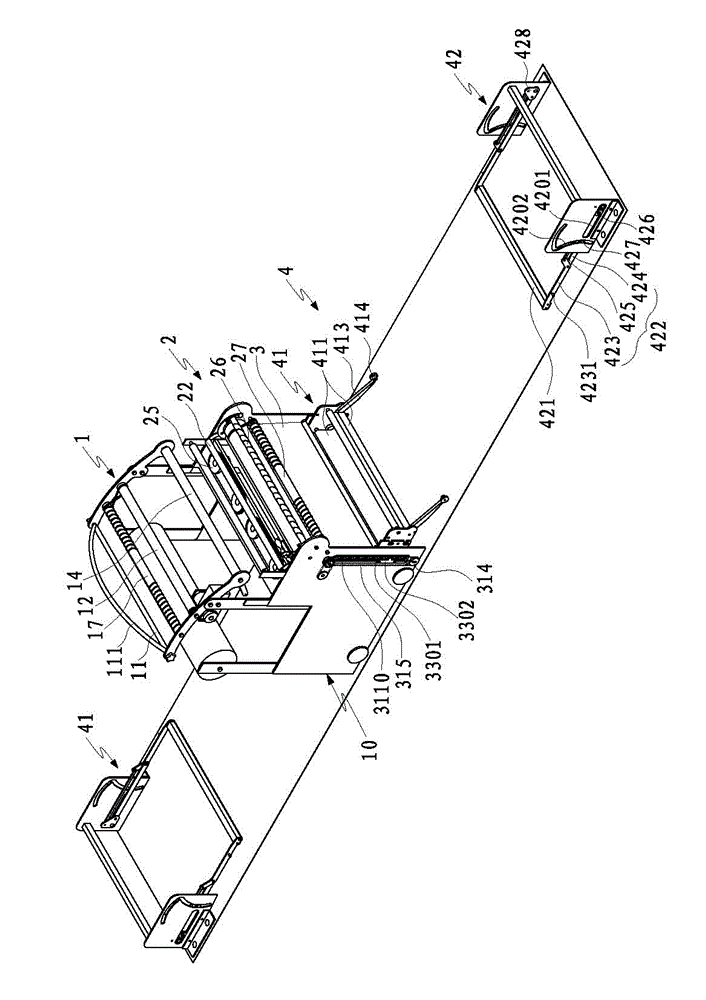

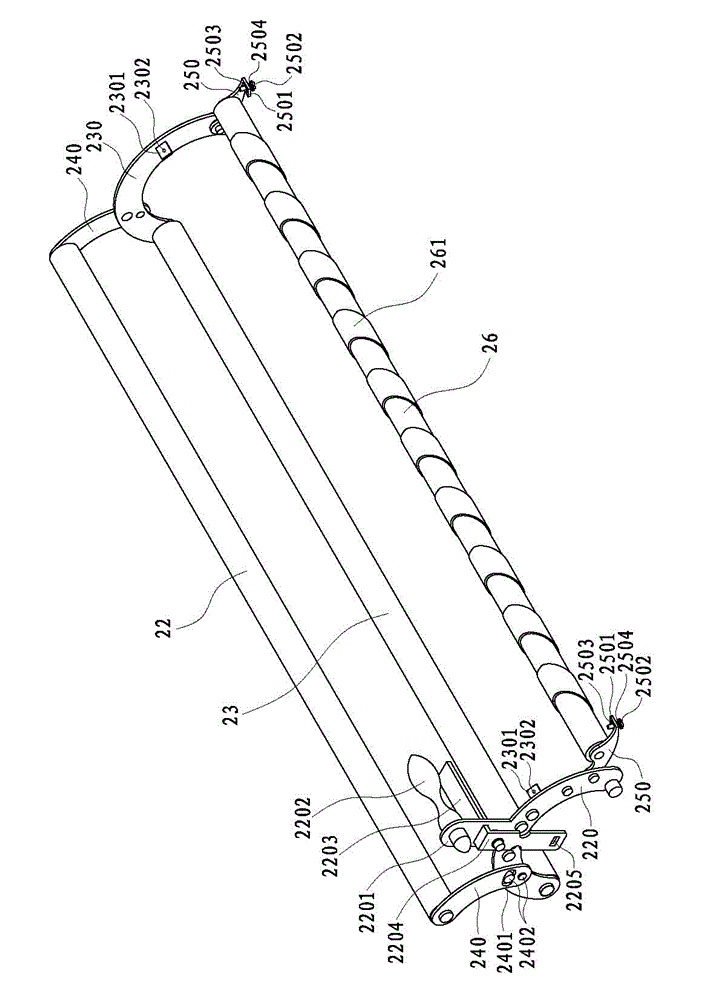

[0097] see Figure 1 to Figure 27 , the present invention discloses a spreading machine, which includes a frame and a cloth feeding device 1, a spreading device 2 and a spreading device 4 arranged on the frame;

[0098] The cloth feed device 1 includes a first cloth guide roller 11, a first cloth feed roller 12, a tension roller 13 and a first cloth outlet roller 14, and the first cloth guide roller 11, the first cloth feed roller 12 and the first cloth feed roller 14 A cloth outlet roller 14 is arranged parallel to and sequentially on the frame 10, the first cloth feed roller 12 is driven to rotate by a motor 15, and both ends of the tension roller 13 are pivotally connected to the first cloth outlet roller through the pivot arm 31 14 both ends; the corresponding cloth passes through the first cloth guide rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com