Workpiece procedure transferring mechanical arm

A technology of manipulators and workpieces, which is applied in the field of robots, can solve problems such as labor-intensive operators, loud noises, and damage to brake discs, and achieve the effects of simple structure, high operation accuracy, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

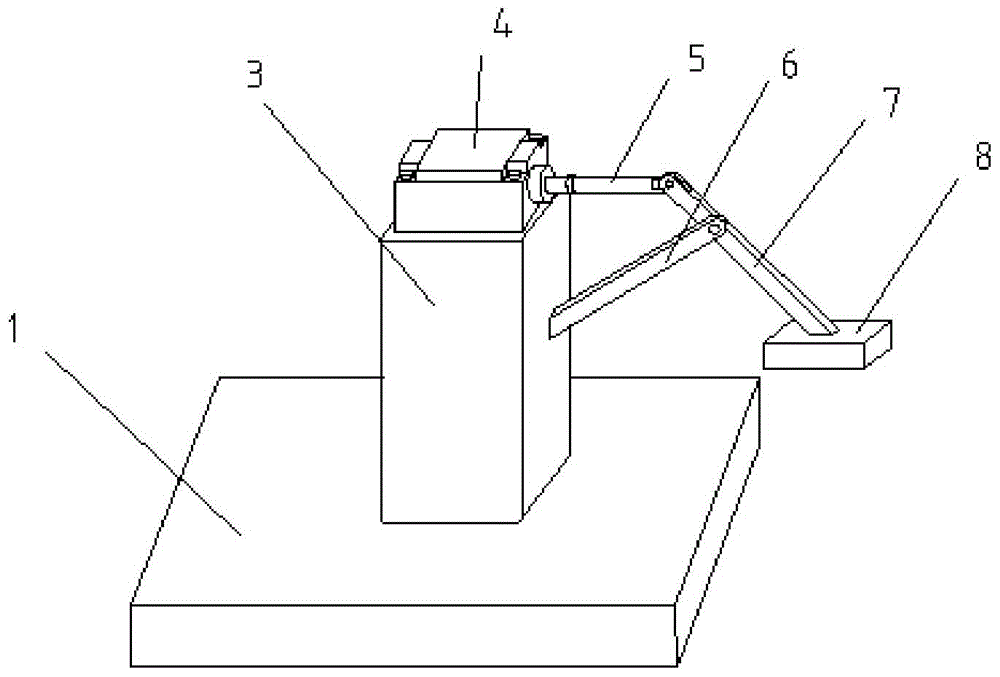

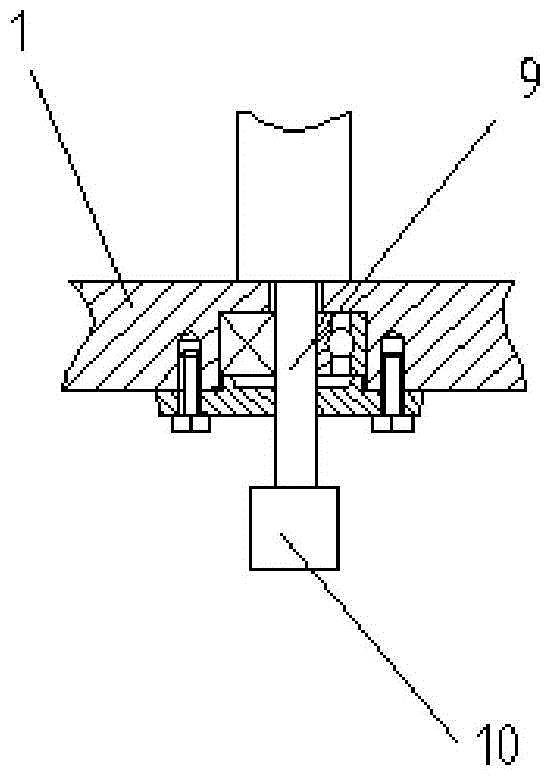

[0017] Such as figure 1 and figure 2 As shown, a workpiece transfer sequence manipulator includes a flat plate 1 and a rotating column 3, the rotating column 3 is vertically arranged, and the lower part of the rotating column 3 is integrally formed with a rotating shaft 9, and the rotating column 3 passes through the rotating shaft 9 and the flat plate 1 Rotationally connected, a bearing is provided between the rotating shaft 9 and the flat plate 1, and a cylinder 4 is provided on the top of the rotating column 3. The piston rod of the cylinder 4 is fixedly connected to one end of the first connecting rod 5, and the other end of the first connecting rod 5 It is hinged with one end of the second connecting rod 7, and the other end of the second connecting rod 7 is fixedly connected with a horizontally arranged suction cup 8, and an electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com