Singe-driving and double-direction type AGV

A single-drive, directional wheel technology, used in motor vehicles, transportation and packaging, etc., can solve the problems of increased cost, inability to go straight, and high manufacturing costs, and achieve the effect of saving costs and motor power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

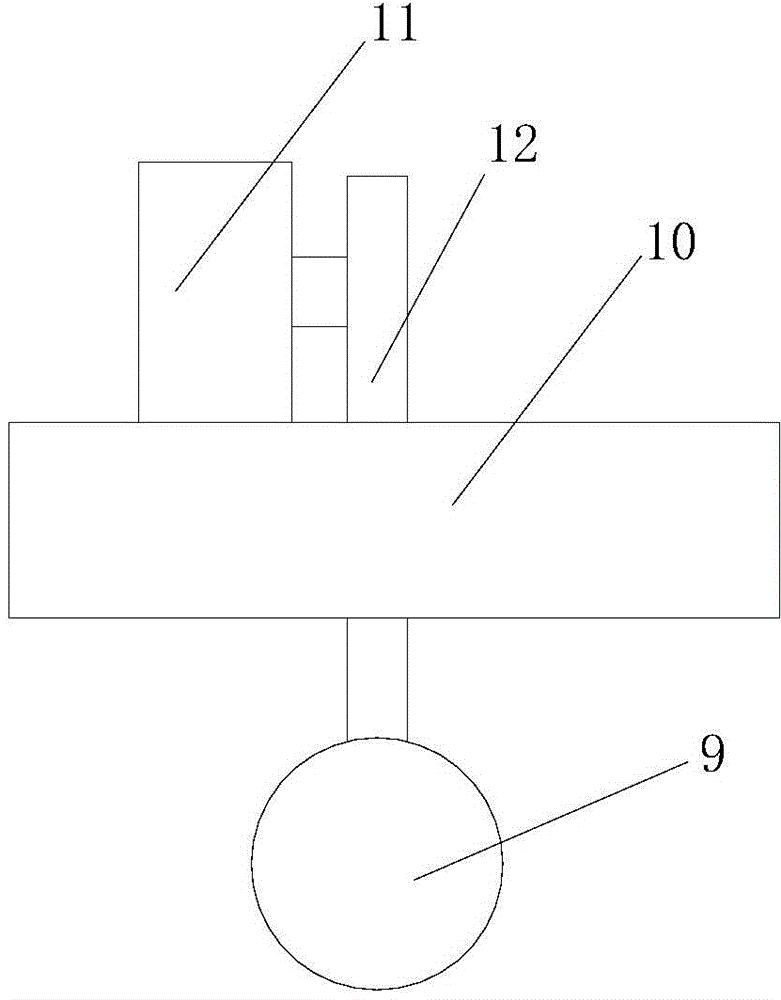

[0017] see figure 1 The single-drive two-way AGV of the present invention includes a car body 1, a navigation sensor 2 and a controller (not shown) arranged on the car body 1, a drive assembly 3 arranged under the car body 1, The first universal wheel set 4 and the second universal wheel set 5 arranged at the bottom of the vehicle body 1 face to face, and the safety devices 8 are arranged at the front and rear ends of the vehicle body 1 . Wherein, the drive assembly 3 includes a drive wheel 31 and a power unit (not shown), the power unit is connected to the drive wheel 31 by transmission, and the drive assembly 3 is connected to the controller and can be moved relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com