Efficient constant pressure difference intermittent rotating extrusion abrasive flow polishing device

A polishing device and intermittent technology, which is applied in the field of high-efficiency constant pressure difference intermittent rotary extrusion abrasive flow polishing device, can solve the problems of excessive material removal, loose abrasive grains, over-polishing, etc., and improve the uniformity of grinding and polishing. The processing surface is uniform and the grinding and polishing effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

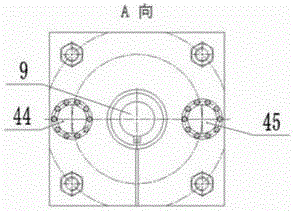

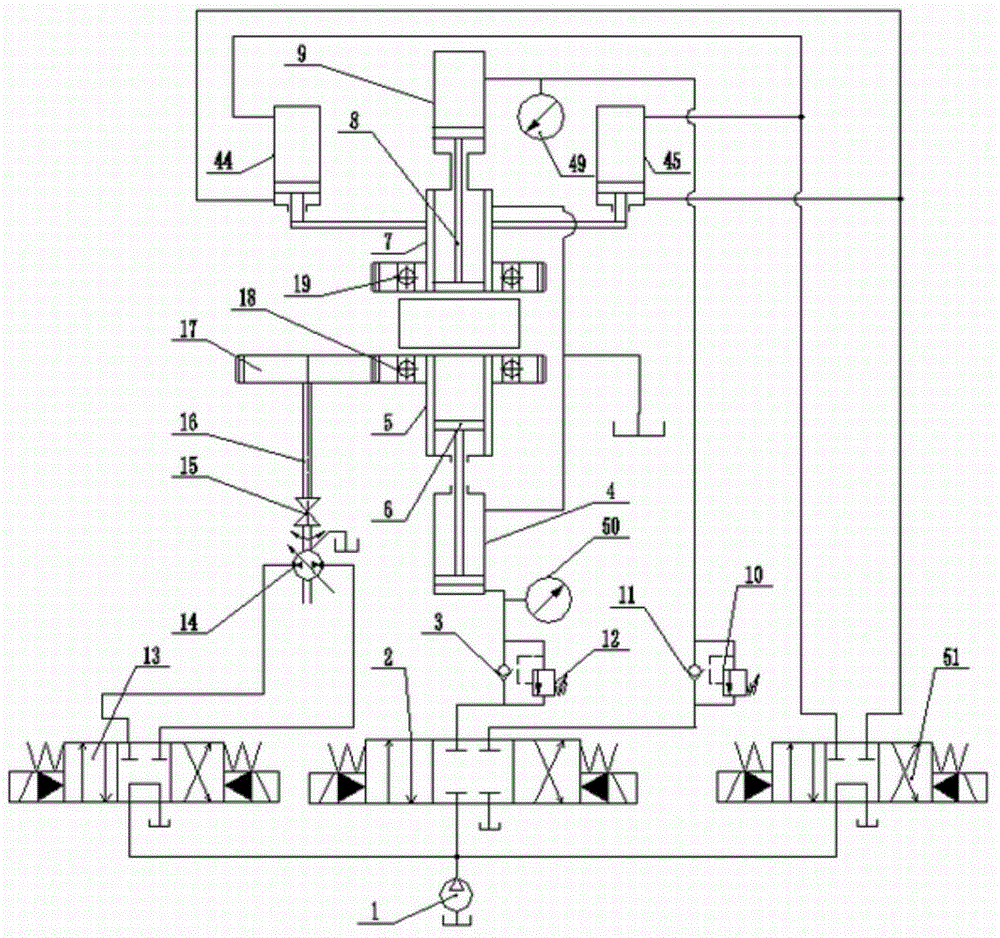

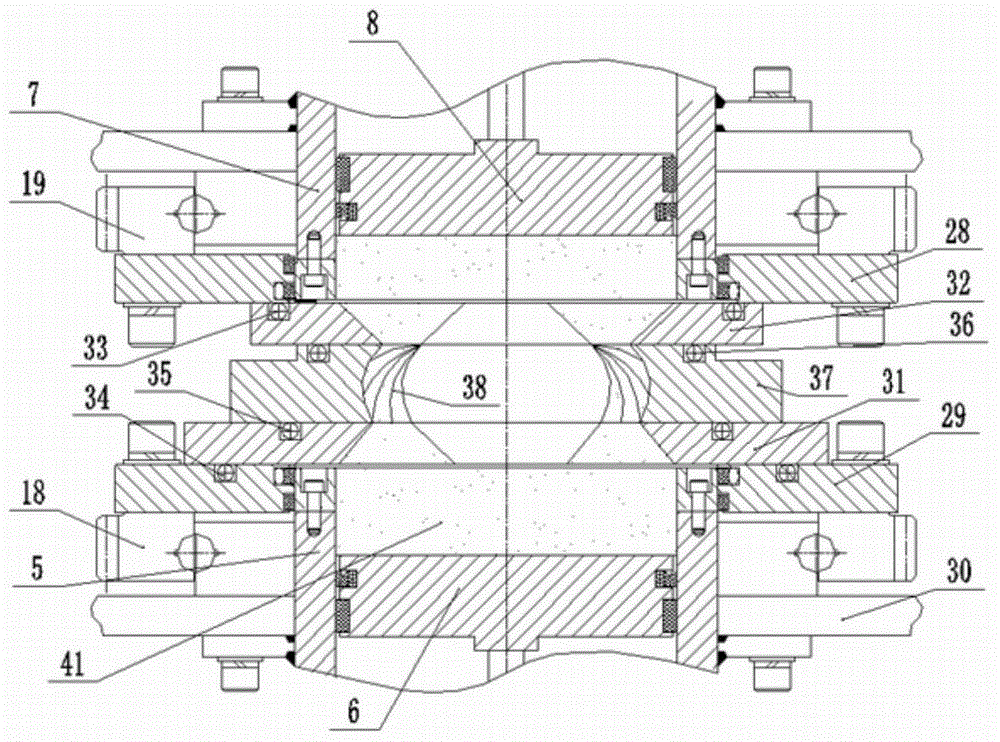

[0025] The above-mentioned abrasive flow polishing device includes a hydraulic transmission bidirectional feeding system, a turntable bearing rotation system, a high-pressure sealing system and a slide rail system.

[0026] The hydraulic transmission two-way feeding system uses the hydraulic pump 1 to pump high-pressure oil through the first three-position four-way reversing valve 2 and the first one-way valve 3 into the lower extrusion cylinder 4, and passes through the lower extrusion cylinder 4 and the lower cylinder The first interlocking push piston 6 in 5 pushes the abrasive through the sealed cavity formed by the processed workpiece 38 and the chuck body, and squeezes to the second interlock push piston 8 located in the upper extrusion cylinder 9 and the upper cylinder 7. Extrusion, grinding and polishing device drives the upper extrusion cylinder 9 to return oil through the second linkage pusher piston 8, and the returned oil flows through the first three-position four-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com