Process for welding reinforcing rings between topside module and jacket

A welding process and strengthening ring technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor welding forming, high skill level requirements of workers, low deposition rate, etc., to improve welding and qualified The effect of reducing the operating skill requirements and increasing the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Such as figure 1 — Figure 6 as shown,

[0030] The present invention adopts following steps:

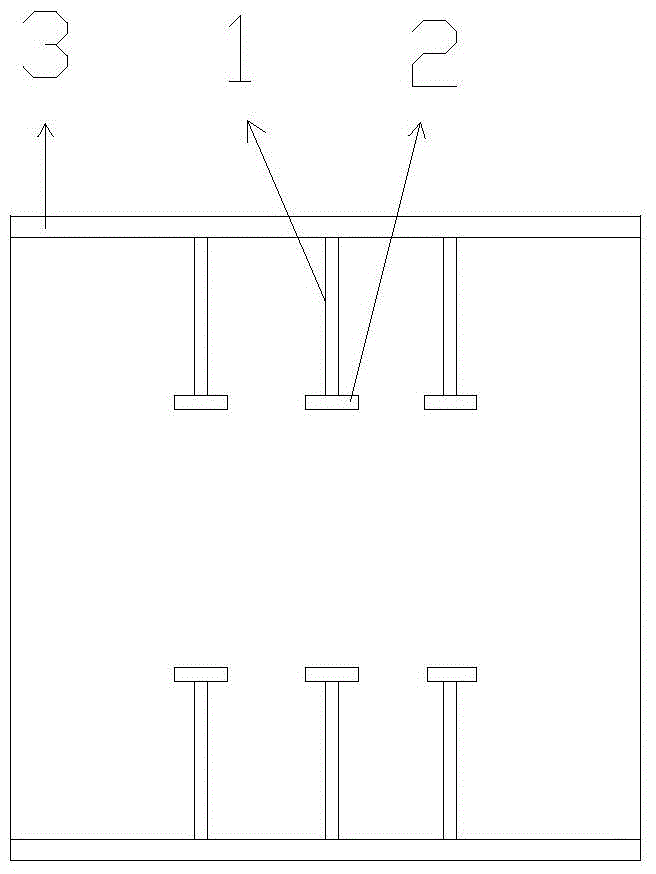

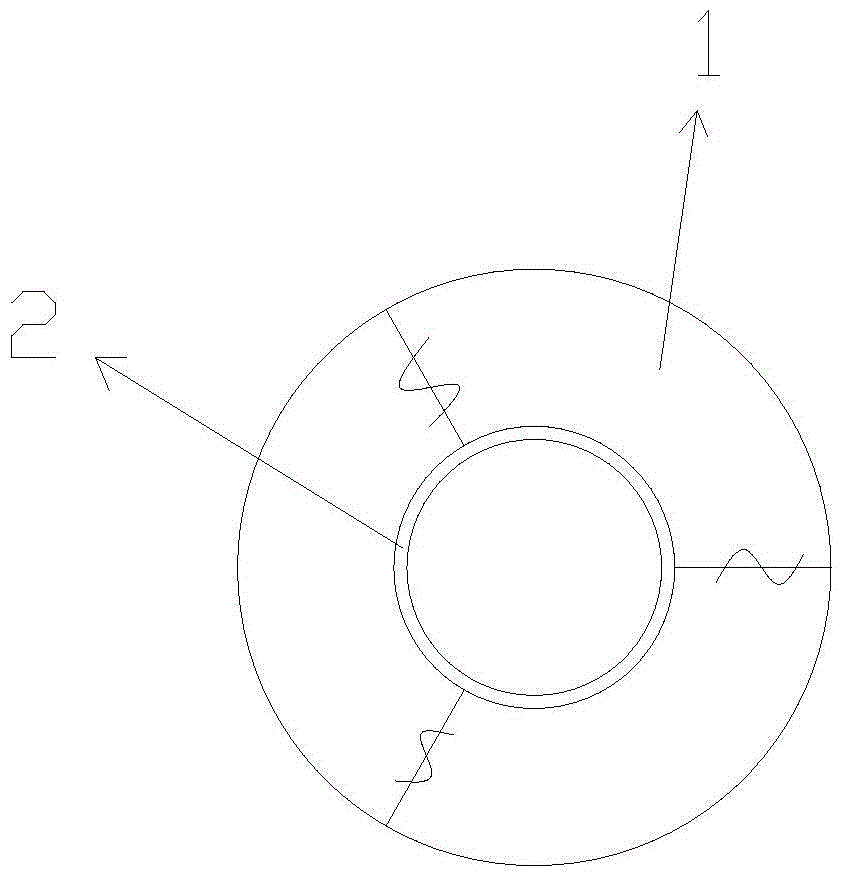

[0031] The first step: if figure 2 As shown, first take a reinforcement ring as a unit, carry out welding prefabrication of the reinforcement ring and the inner flange ring 2 on the outside of the jacket and the upper block; during prefabrication, a reinforcement ring is divided into several arc-shaped plates 1, and then Several arc-shaped plates 1 are spliced together by X-shaped groove and double-sided welding to form an integral reinforcing ring;

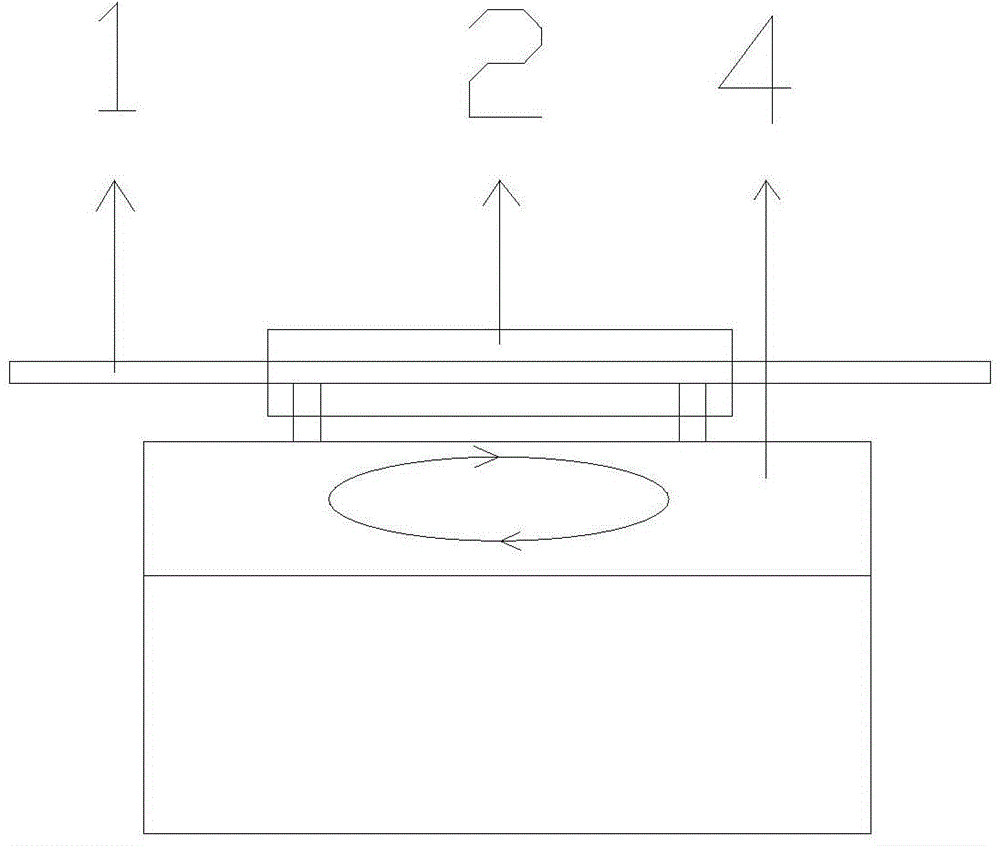

[0032] The second step; if image 3 As shown, assemble the flange ring 2 of the reinforcement ring, place the flange ring 2 on the positioner 4, and use the submerged arc welding machine to weld the flange ring 2 on the arc-shaped plate 1. When welding, the K-type Groove, ring seam of flange ring 2 welded on both sides;

[0033] Step 3: If Figure 4 As shown, make a K-shaped bevel on the outer edge of the reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com