Honeycomb core milling platform

A technology of honeycomb core and working platform, which is applied in the direction of milling machine equipment, milling machine equipment details, large fixed members, etc., can solve problems such as difficult to control the angle of milling, reduce work efficiency, and product scrapping, so as to avoid instability and unsatisfactory Accurate, low component accuracy requirements, and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

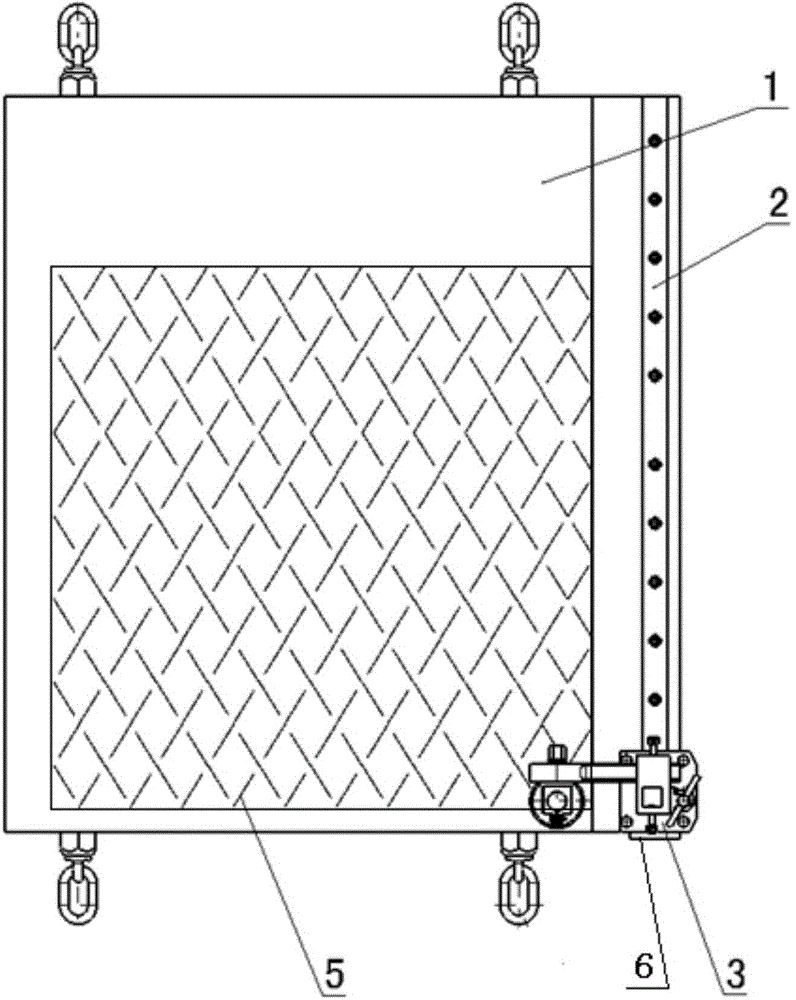

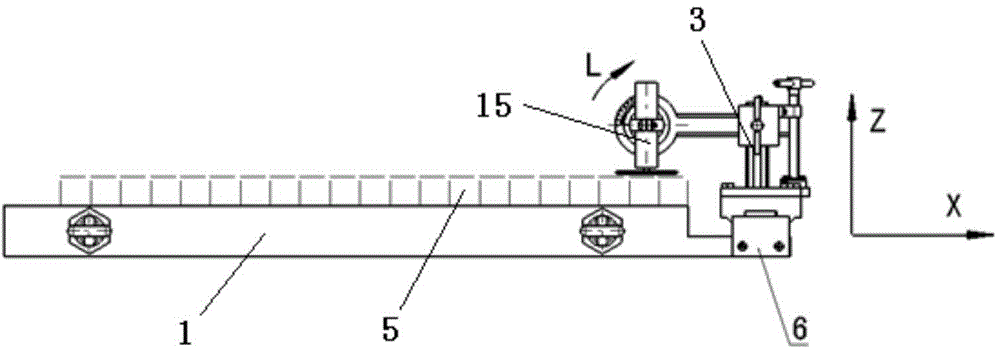

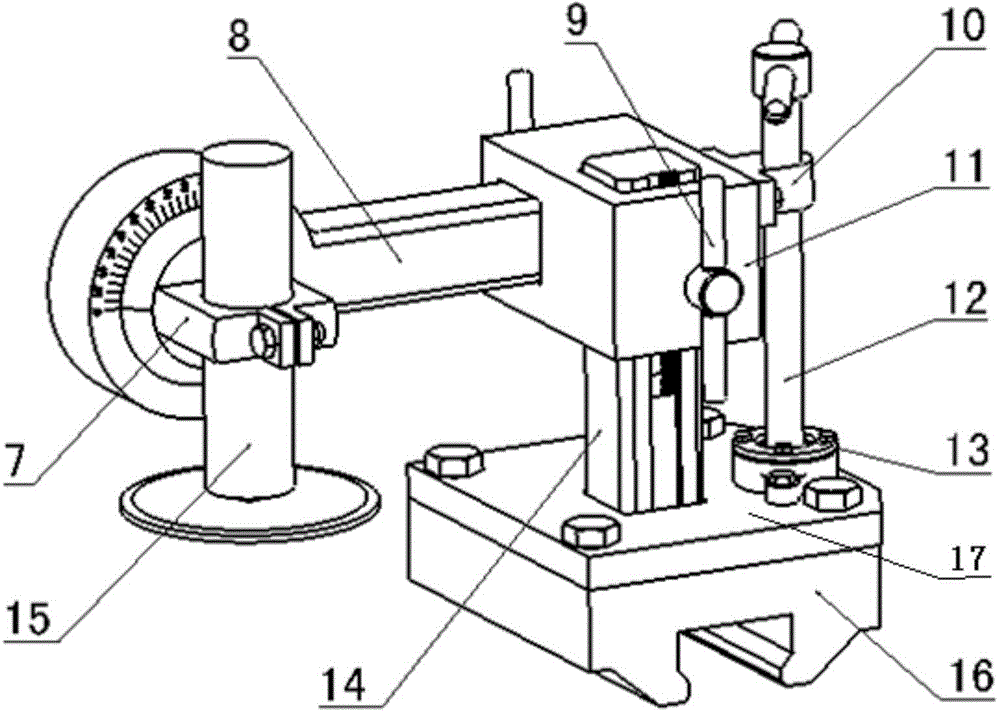

[0013] The honeycomb core milling platform of the present application is as follows figure 1 , figure 2 As shown, it includes a working platform 1, a guide rail 2 and a transmission mechanism 3, and the part 5 to be processed is a honeycomb core board, which needs to be milled. Paste the part 5 to be processed on the work platform 1, and adjust the height (Z direction), left and right (X direction) and angle (L direction) position of the tool 15 through the transmission mechanism 3. After the tool is fixed, the worker can directly The transmission mechanism starts from the limit stop 6 and processes the product along the direction (Y direction) of the guide rail 2 .

[0014] The key of the present application is how to control the position of the cutter, so as to free the hands of the worker, so as to achieve the purpose of convenience, speed and precision. The transmission mechanism 3 is the device used to control the position of the tool.

[0015] transmissions such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com