Motor case one-step turning method and clamp

A technology for turning machining and casing, applied in the field of one-tool turning machining method of motor casing and its fixture, can solve the problems of difficulty, increased processing, high requirements on casing size and tolerance, etc., to improve noise and temperature rise, and improve work efficiency , to ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

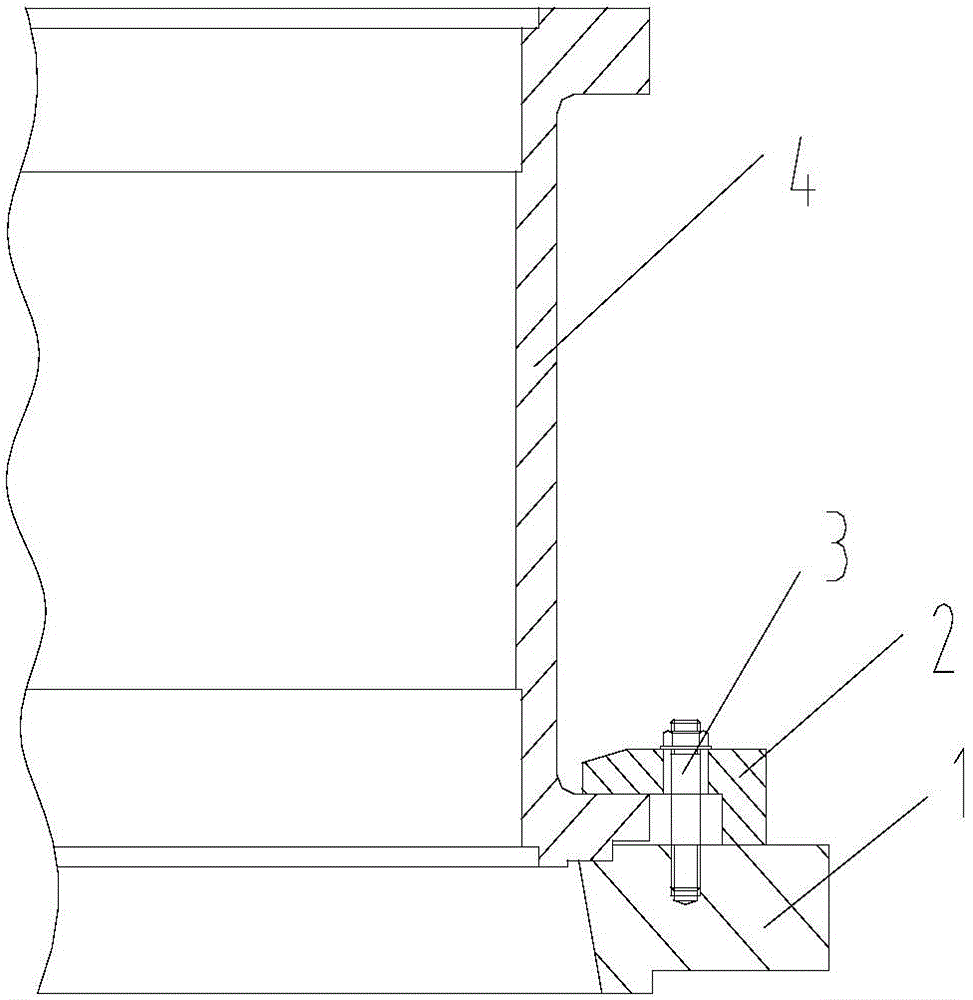

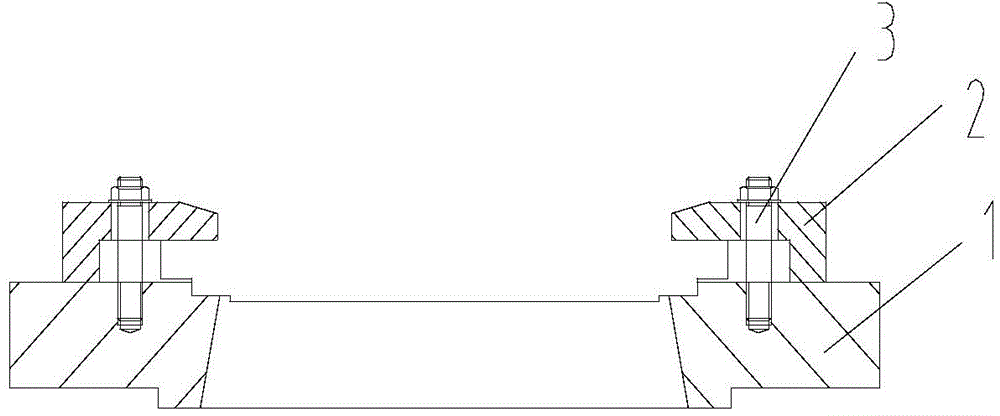

[0016] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] When finishing the planes, seams and inner holes of the high-efficiency motor casing, the KRCK518G CNC vertical machine tool and its special fixtures are used to complete the "one-tool lathe" processing technology to complete the entire process. The assembly method of the workpiece and the fixture during processing Such as figure 1 shown;

[0018] The processing method steps are as follows:

[0019] a. Roughly machine the inner hole of the motor casing, the end face and the inner stop at the end face on the double-sided rough boring machine, and leave a finishing allowance of 1 to 1.5 mm on one side; considering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com