A method for detecting liquid steel liquid level and mold slag liquid slag layer thickness in mold

A crystallizer and liquid slag layer technology, which is applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to monitor the thickness of liquid slag layer in real time and operational uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

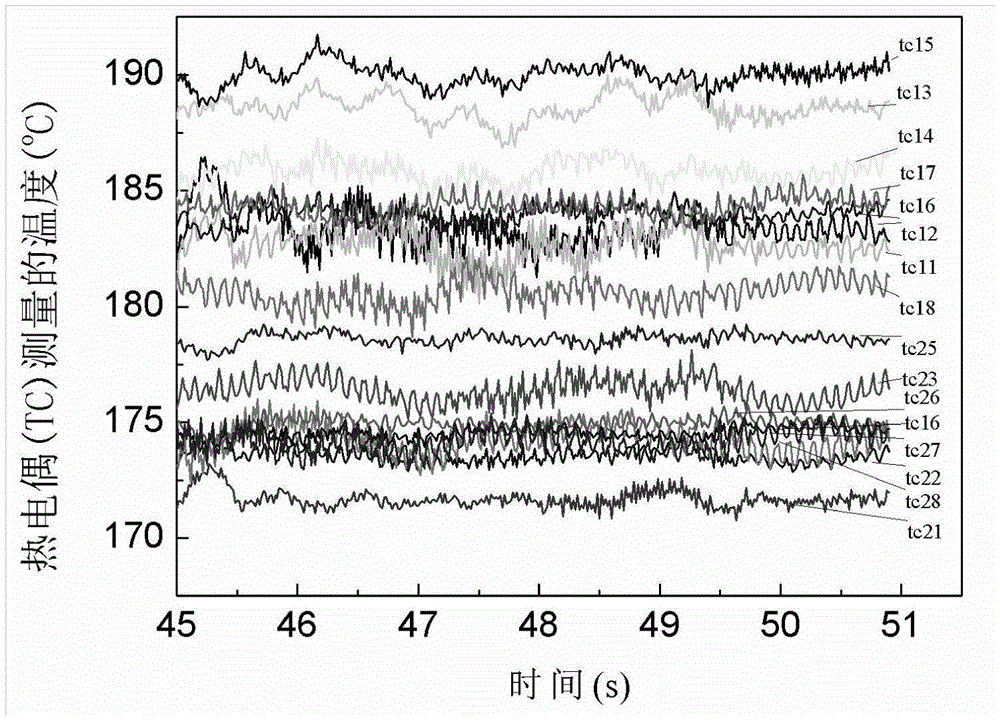

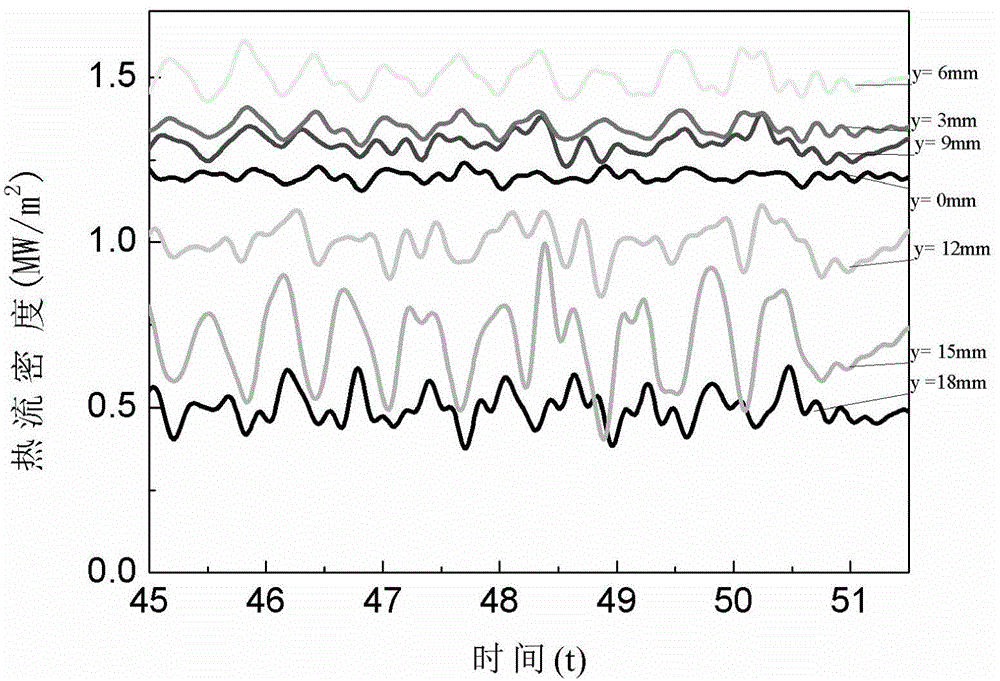

[0133] Cast Q235 steel, the casting temperature is 1530°C, the casting speed is 0.53m / min, the crystallizer vibration frequency is 1.67Hz, and the amplitude is 3mm.

[0134] In the process of using the present invention to detect the molten steel level in the crystallizer and the thickness of the mold slag liquid slag layer, four steps are adopted: 1) temperature measurement / collection in the mold wall, 2) inverse calculation of heat flux density, 3) heat flux density spectrum 4) interface identification to determine the position of the liquid steel level and the position of the liquid slag layer, so as to detect the liquid steel level and the thickness of the liquid slag layer.

[0135] step one

[0136] Such as figure 1 Shown: Along the height direction of the mold wall, two sets of thermocouples are installed in the copper wall of the mold corresponding to the molten steel level and the liquid slag layer, that is, along the height direction of the mold wall, the average te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com