Continuous die feeding and anti-dislocation method

A technology of anti-displacement and material feeding, applied in the field of continuous mold, can solve the problems of manual observation and judgment, and achieve the effect of ensuring normal use and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

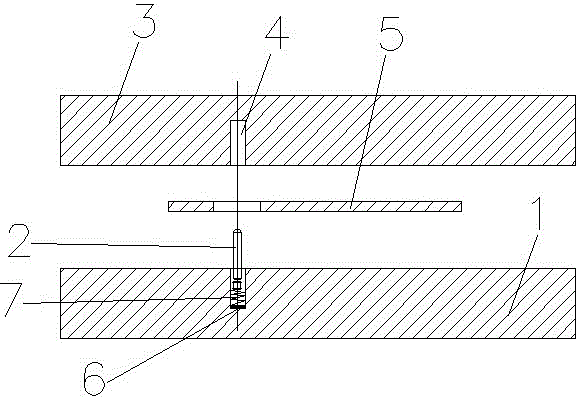

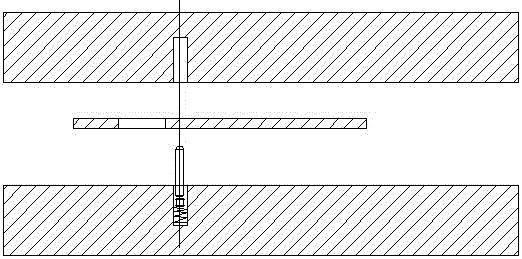

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] see figure 1 and figure 2 , as can be seen from the figure, the present invention’s method for preventing misalignment of continuous die feeding, pre-installs the upward detection pin 2 on the lower die 1, and sets the pin hole 4 at the corresponding position of the upper die 3, and the detection pin 2 is facing the pin hole 4. During normal feeding, the pin hole 4 is facing the hollow position of the workpiece 5, that is, the hole between the detection pin and the pin hole is the opening part of the workpiece. During each processing, since there is no obstruction, the detection pin can enter the pin hole. See figure 1 , since the pin hole is larger than the diameter of the detection pin, and the detection pin cannot reach the bottom of the pin hole, so the detection pin has no force. When the feed is not in place, such as too much or too little feed, when the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com