Door frame, door frame bending die and bending method

A technology for bending molds and door frames, which is applied in the field of molds and bending, can solve the problems that door frames cannot be processed, and achieve the effects of good sound insulation, good connection, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

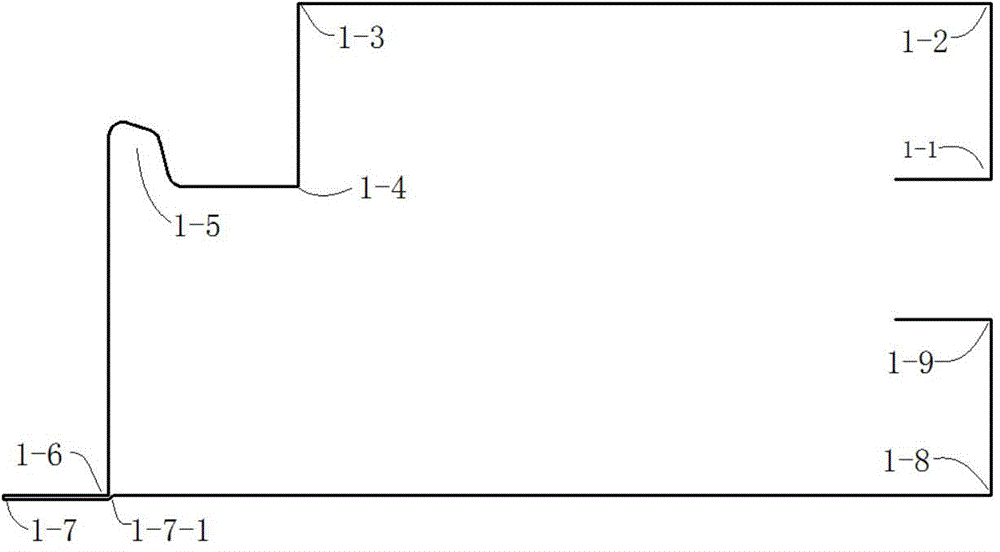

[0048] combine figure 1 , a door frame of this embodiment, the door frame is integrally bent by a metal plate to form a cavity structure, the cavity structure consists of a first right-angle section 1-1, a second right-angle section 1-2, a third right-angle section 1-3, the fourth right-angle section 1-4, the hemming protrusion 1-5, the fifth right-angle section 1-6, the flattening section 1-7, the transition section 1-7-1, the sixth right-angle section 1-8 It is connected with the seventh right-angle segment 1-9 in sequence (such as figure 1 ), wherein: the flanging protrusion 1-5 includes three angle transition sections, the flattening section 1-7 is an overlapping section with an included angle of 0°, and the flattening section 1-7 passes through the transition section 1-7-1 and The sixth right-angle segment 1-8 is connected, and the length of the overlapping segment of the flattened segment 1-7 and the fifth right-angle segment 1-6 is greater than 13.5 mm.

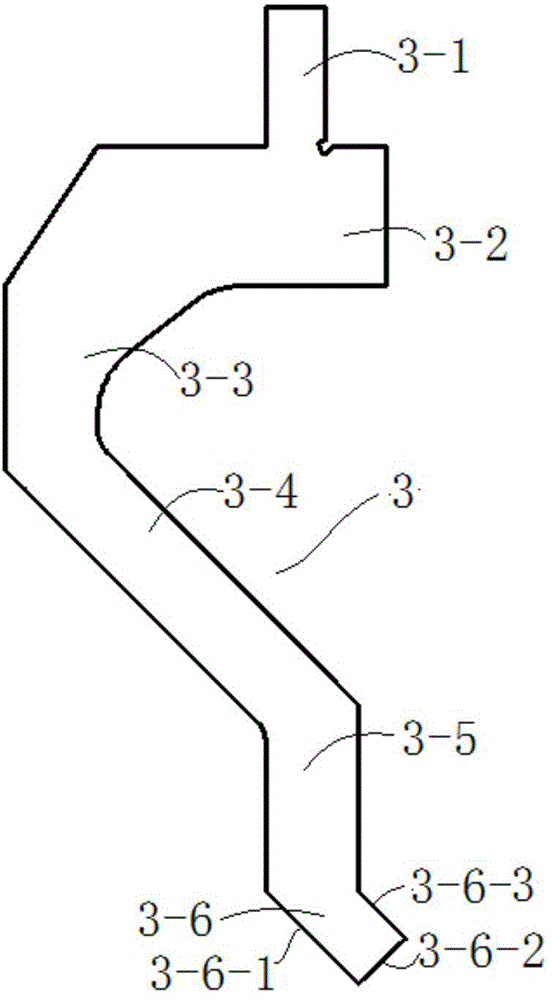

[0049] combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com