Turntable-type runoff electrode plate dust collector

An electrode plate and rotary disc type technology, which is applied in the field of rotary disc runoff electrode plate dust collector, can solve the problems of unable to meet the requirements of dust removal, difficulty in meeting processing requirements, and reduced air flow of electrostatic precipitators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

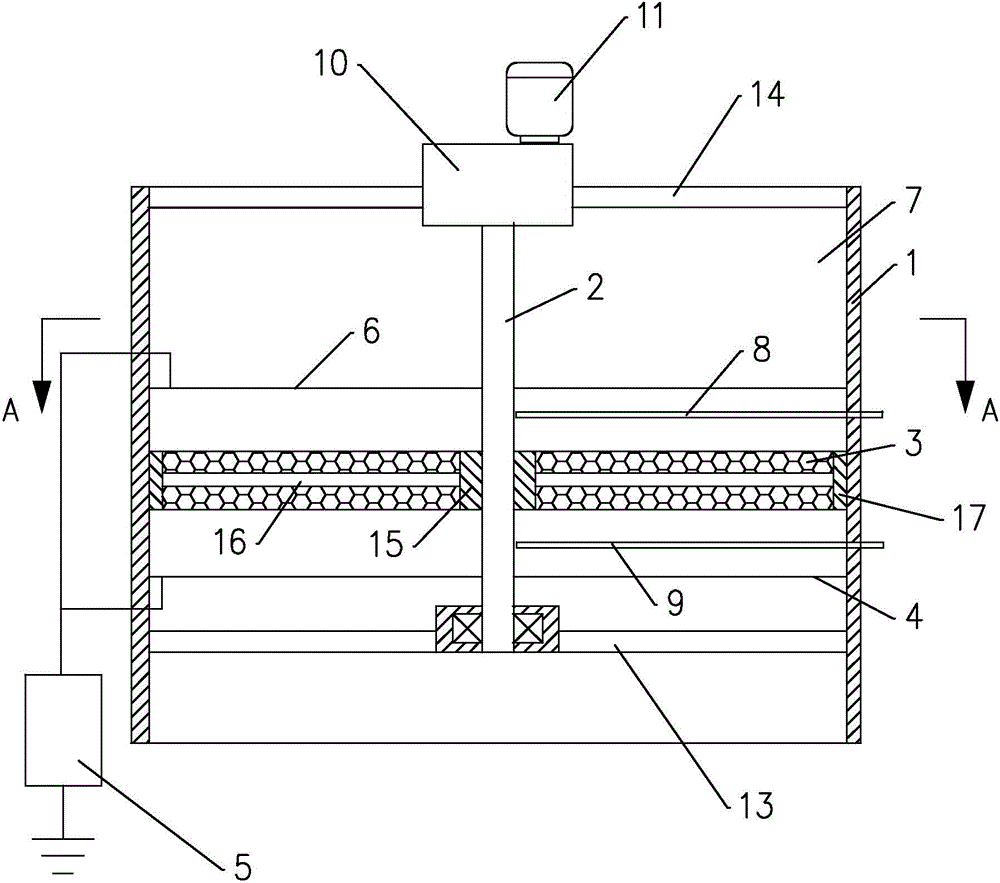

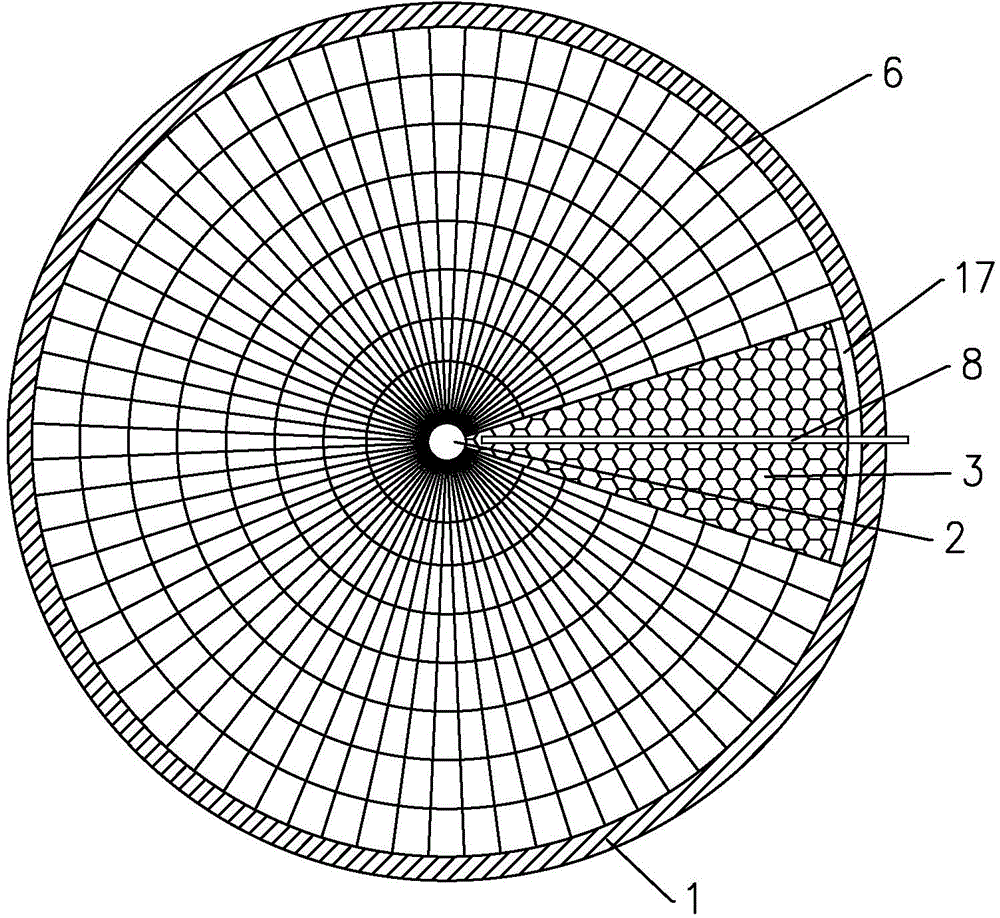

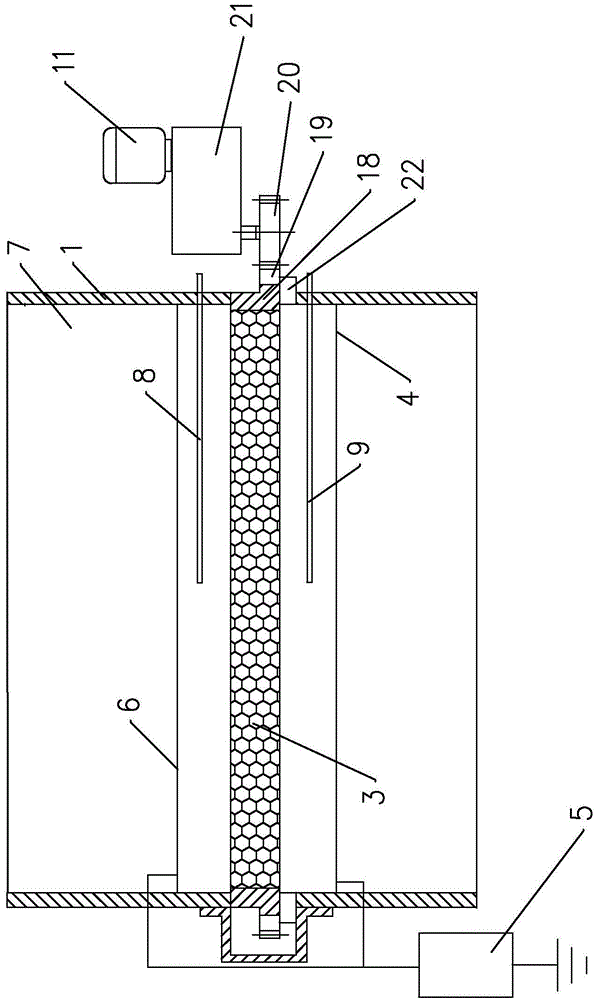

[0020] like figure 1 and figure 2 As shown in the figure, the rotary disk type runoff electrode plate dust collector of the present invention includes a casing 1, and a dust gas duct 7 is arranged in the casing 1, and an electrode plate 3 whose plate surface can be ventilated is arranged in the dust gas duct 7. The electrode plate 3 The plate surface is located in the cross-sectional direction of the dust and gas duct 7, the electrode plate 3 is provided with a front discharge net 4 in front of the direction of the inlet end of the dust and gas duct 7, the plate surface of the electrode plate 3 facing the front discharge net 4 is a plane, and the electrode plate 3 It can be rotated in the dust and gas duct 7 under the driving of the prime mover 11. The plate surface of the electrode plate 3 facing the inlet end of the dust and gas duct 7 is always kept parallel to the mesh surface of the front discharge mesh 4 during the rotation process. The front discharge mesh 4 A potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com