Fiber catalytic material for purifying formaldehyde gas and preparation method thereof

A catalytic material and fiber technology, applied in the field of photocatalysis, can solve the problems of reduced activity, poor mechanical properties, poor filterability and durability, complicated preparation process, etc., and achieve the effect of enhanced practicability and excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1) Choose a thickness of 1.5mm and a weight of 166g / m 2 , Acrylonitrile monomer content of 86.52% polyacrylonitrile non-woven fabric as the carrier material, accurately weigh 1.0g of this non-woven fabric into 40ml of hydroxylamine hydrochloride solution with a concentration of 45g / L, adjust the pH to 6.0, The reaction was carried out at 85°C and stirring for 150 minutes, and then removed and repeatedly washed and dried with distilled water to obtain a modified polyacrylonitrile non-woven fabric.

[0014] 2) Weigh 1.0g of modified polyacrylonitrile non-woven fabric and place it in 50ml of ferric chloride aqueous solution with a concentration of 0.02mol / L, carry out the coordination reaction at 50℃ and stirring conditions, take it out after 120min and wash it repeatedly with distilled water Drying to obtain the first polyacrylonitrile non-woven fabric iron complex catalyst material.

[0015] The atomic absorption method was used to determine the change of the iron ion concent...

Embodiment 2

[0017] The concentration of ferric chloride in step 2 of Example 1 was adjusted to 0.1 mol / L, and the rest was the same as that of Example 1, to obtain the second polyacrylonitrile non-woven fabric iron complex catalyst material. After measurement and calculation, its iron ion content is 118mg / g.

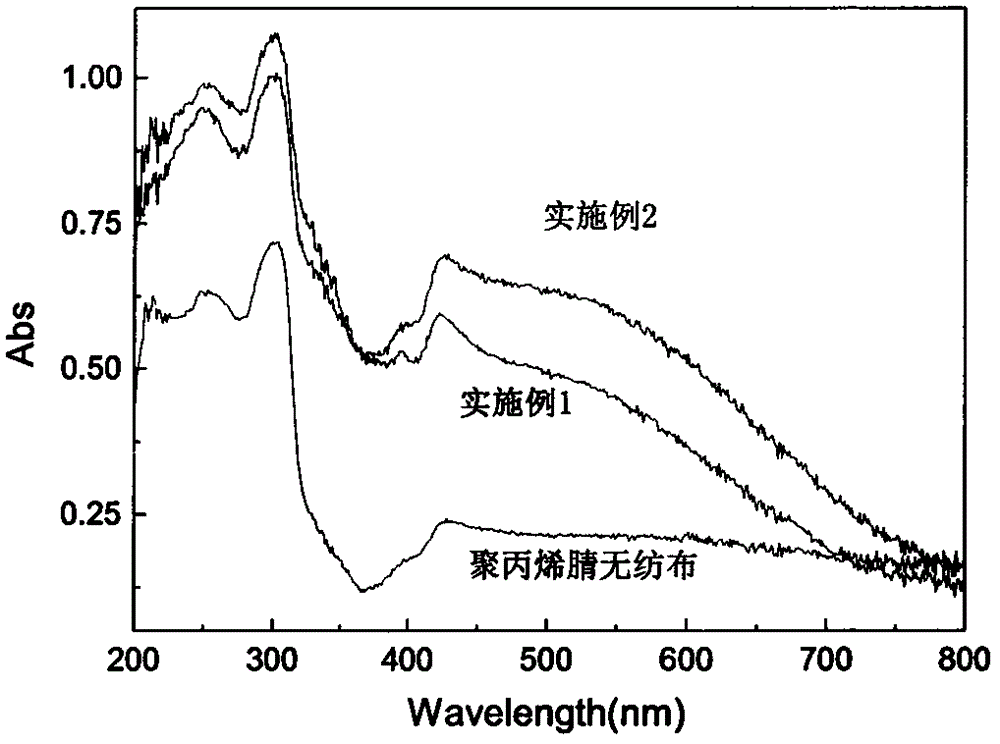

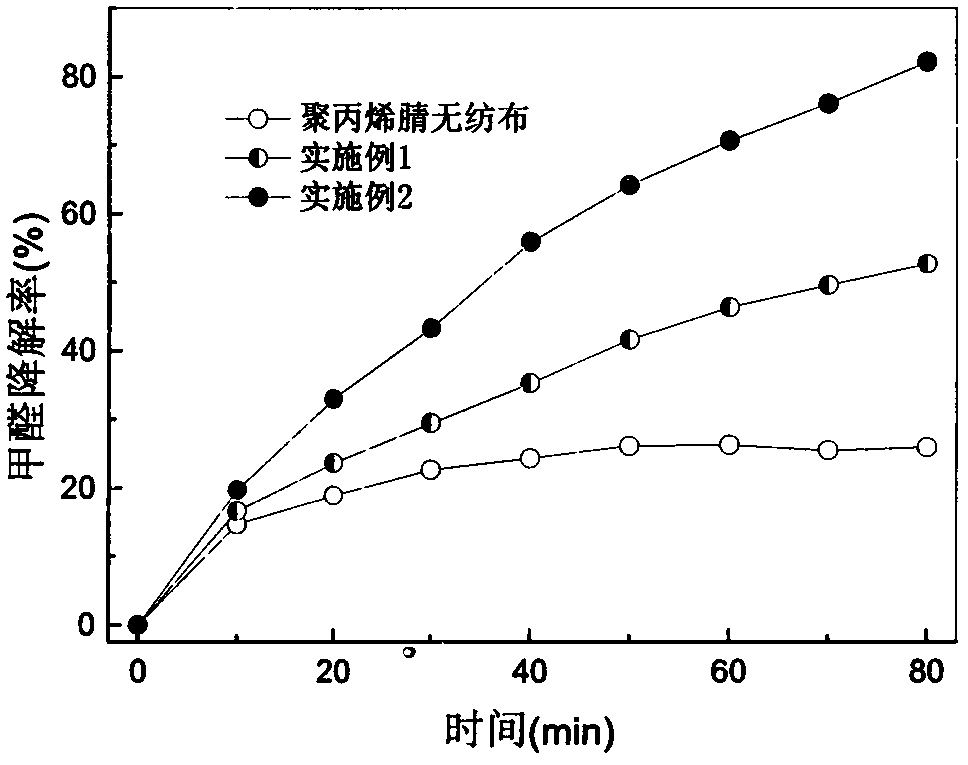

[0018] A Thermo Scientific Evolution220 UV-Vis spectrophotometer was used to measure the absorption spectra of the two examples and the polyacrylonitrile non-woven fabric in the range of 200-800nm. The results are shown in figure 1 Shown. The light absorption area of the polyacrylonitrile non-woven fabric is mainly concentrated in the ultraviolet region of 200-400nm, and the two examples have obvious absorption bands in the visible light region of 400-800nm, and Example 2 with a higher iron ion content shows Higher absorption strength. This absorption peak is mainly due to Fe 3+ D-d electronic transition and the ligand to Fe 3+ Due to the LMCT effect, it provides conditions for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com