Kieselguhr-based particle adsorbent and preparation and modification method thereof

A particle adsorbent, diatomite technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., to achieve the effect of improving surface properties, simple method, and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

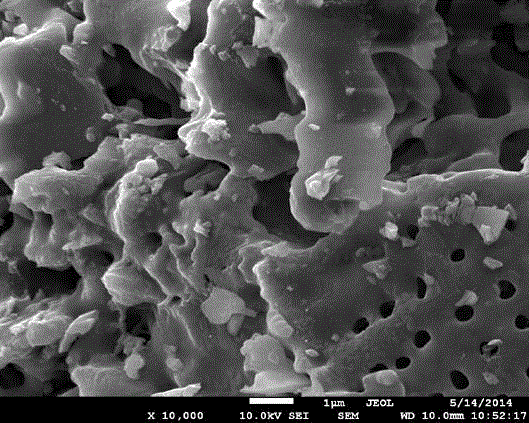

Image

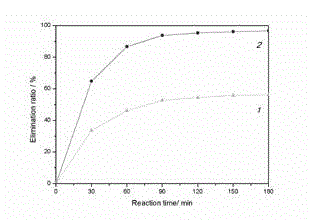

Examples

Embodiment 1

[0025] The diatomite-based granular adsorbent is made of the following raw materials in weight ratio: 79g diatomite, 6g kaolin, 4g feldspar, 3g sodium chloride, 2g montmorillonite, 6 sodium carbonate, 5 carbon powder (pore forming agent, Add), oleic acid 0.6, water 16mL.

[0026] When preparing, weigh the above various raw materials in proportion, mix the raw materials, and dry grind to D 50 = 5 μm, molded in a rolling ball molding machine for 10 minutes, and calcined at 980 ° C for 2 hours to obtain a diatomite-based particle adsorbent.

[0027] The method for modifying the diatomite-based granular adsorbent comprises the following steps: (1) placing the diatomite-based granular adsorbent in an ultrasonic oscillator, ultrasonically cleaning it with tap water, and then drying it at 105°C for use; (1 ) with 0.5mol / L FeCl 3 Mix 10mL of the solution with the diatomite-based granular adsorbent treated in the previous step, stir well, then raise the temperature to 30°C, adjust th...

Embodiment 2

[0032] The diatomite-based granular adsorbent is made of the following raw materials in weight ratio: 86g diatomite, 4g kaolin, 2g quartz, 5g sodium chloride, 3g magnesium carbonate, 3 calcium carbonate, 3 water-soluble starch, 1g magnesium stearate , water 18mL.

[0033] When preparing, weigh the above various raw materials in proportion, mix the raw materials, and dry grind to D 50 = 8 μm, molded in a rolling ball molding machine for 20 minutes, and calcined at 1040 ° C for 2 hours to obtain a diatomite-based particle adsorbent.

[0034] The method for modifying the diatomite-based granular adsorbent comprises the following steps: (1) placing the diatomite-based granular adsorbent in an ultrasonic oscillator, ultrasonically cleaning it with tap water, and then drying it at 105°C for use; (2) ) with 0.3mol / L FeCl 3 Mix 10mL of the solution with the diatomite-based granular adsorbent treated in the previous step, stir well, then raise the temperature to 25°C, adjust the solu...

Embodiment 3

[0036]The diatomite-based granular adsorbent is made of raw materials in the following weight ratio: diatomite: 75g, kaolin 10g, feldspar 3g, sodium carbonate 6g, sodium chloride 3g, magnesium carbonate 3g, coal powder 5, carbon powder 3, Sodium oxalate 0.6, water 14mL.

[0037] When preparing, weigh the above raw materials in proportion, weigh the various raw materials in proportion, mix the raw materials, and dry grind them to D 50 =10 μm, molded in a rolling ball molding machine for 15 minutes, and calcined at 920°C for 2 hours to obtain a diatomite-based particle adsorbent.

[0038] The method for modifying the diatomite-based granular adsorbent comprises the following steps: (1) placing the diatomite-based granular adsorbent in an ultrasonic oscillator, ultrasonically cleaning it with tap water, and then drying it at 105°C for use; (2) ) with 1mol / L FeCl 3 Mix 10mL of the solution with the diatomite-based granular adsorbent treated in the previous step, stir well, then ...

PUM

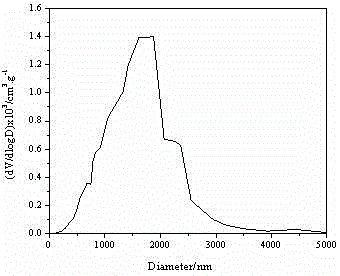

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com