Shredded bread improver, method for preparing same and application of shredded bread improver

A bread improver and hand tearing technology, applied in the food field, can solve problems such as inconvenience of consumers, and achieve the effects of simple raw materials, simple production and application process, and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

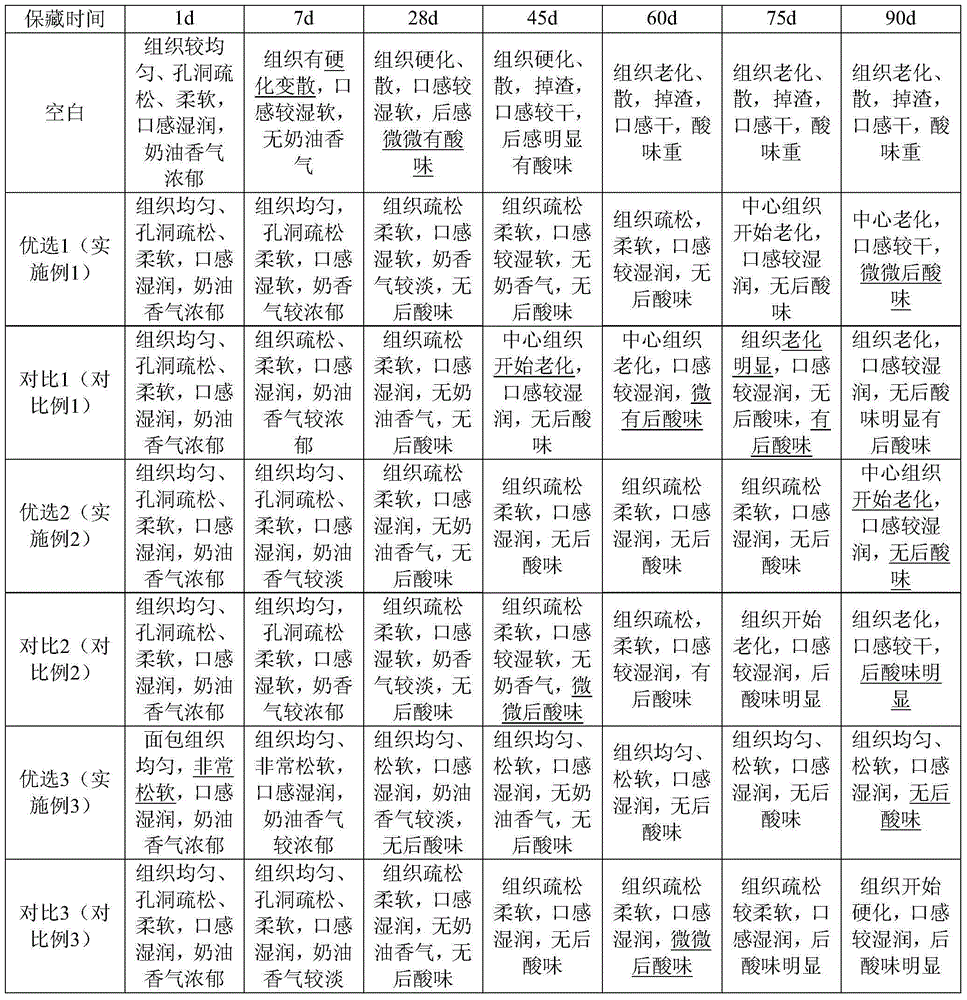

Embodiment 1

[0027] A preferred version of shredded bread improver: sodium stearoyl lactylate 15%, calcium stearoyl lactylate 15%, α-amylase (AB32, Wuxi Innoc Technology Co., Ltd.) 0.3%, lipase (Novozymes, Guangzhou Mingyuan Industry and Trade Co., Ltd.) 0.2%, xanthan gum 10%, ascorbyl palmitate 3%, sodium pyrophosphate 10%, corn starch 46.5%.

Embodiment 2

[0029] A preferred version of shredded bread improver: sodium stearoyl lactylate 15%, sucrose fatty acid ester 5%, α-amylase 0.2%, glucose oxidase (Novozymes, Guangzhou Mingyuan Industry and Trade Co., Ltd.) 0.2%, Gelatin 3%, sodium polyacrylate (Renqiu Wanfang Chemical Co., Ltd., molecular weight 4-10 million) 3%, ascorbyl palmitate 2%, sodium pyrophosphate 3%, calcium dihydrogen phosphate 5%, pregelatinization Starch (French Roquette, PRCH20) 63.6%

Embodiment 3

[0031] A preferred solution of shredded bread improver: sodium stearoyl lactylate 5%, diacetyl tartaric acid mono(dig)glyceride (Henan Zhengtong Chemical Co., Ltd.) 5%, α-amylase 0.1%, lipase 0.1%, glucose oxidation Enzyme 0.1%, Sodium Alginate 3%, Gelatin 2%, Ascorbyl Palmitate 1%, Disodium Dihydrogen Pyrophosphate 2.5%, Sodium Pyrophosphate 2.5%, Dextrin (MD15, Qinhuangdao Lihua Starch Co., Ltd.) 78.7 %

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com