Lithium ion battery electrode structure and preparation method thereof

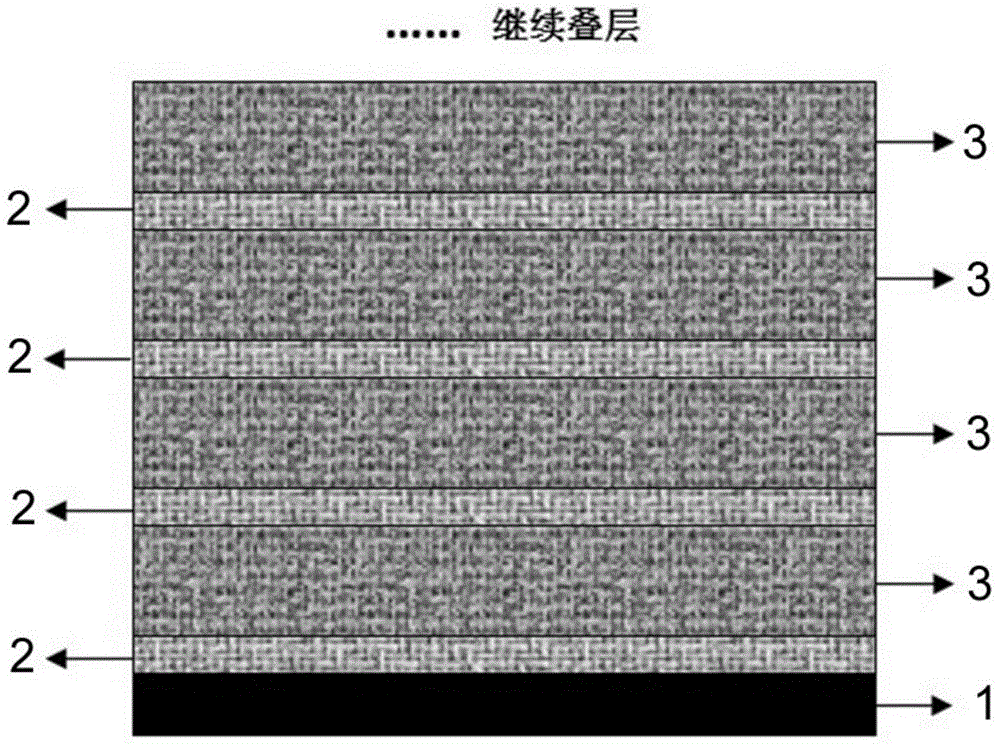

A lithium-ion battery and electrode structure technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problem of further greatly reducing the mass and volume of inactive materials, electron and ion transfer and diffusion The path becomes longer, it is difficult to satisfy the problem, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of graphene coating slurry: First, dissolve 2 g of sodium carboxymethyl cellulose in 198 g of deionized water, use a mechanical stirrer to stir at a rate of 700 rpm for 1 h until uniform, and prepare 1% carboxymethyl cellulose The aqueous solution of sodium methylcellulose; the graphene water-based conductive paste obtained by 50g intercalation stripping method is added in the sodium carboxymethylcellulose solution of 1% content (wherein the content of graphene in the graphene water-based conductive paste is 4%, the number of graphene layers is 3-7 layers, and the typical size of graphene is 5-10 μm), figure 2 It is a transmission electron microscope picture of graphene after freeze-drying the graphene conductive paste. From the high-resolution transmission electron microscope picture, we can see that the number of layers of graphene is 4. Use a mechanical stirrer to stir at a rate of 700 rpm for 1 h until the graphene slurry is uniformly dispersed in a ...

Embodiment 2

[0037] 1. Preparation of graphene coating slurry: First, dissolve 2 g of sodium carboxymethyl cellulose in 198 g of deionized water, use a mechanical stirrer to stir at a rate of 700 rpm for 1 h until uniform, and prepare 1% carboxymethyl cellulose The aqueous solution of sodium methylcellulose; the graphene water-based conductive paste obtained by 50g intercalation stripping method is added in the sodium carboxymethylcellulose solution of 1% content (wherein the content of graphene in the graphene water-based conductive paste is 4%, the number of graphene layers is 3-7 layers, and the typical size of graphene is 5-10 μm). Use a mechanical stirrer to stir at a rate of 700 rpm for 1 h until the graphene slurry is uniformly dispersed in a 1% sodium carboxymethylcellulose solution to prepare a graphene-coated slurry.

[0038] 2. Preparation of lithium iron phosphate coating slurry: weigh 64g of lithium iron phosphate, 8g of conductive carbon black SP, 8g of polyvinylidene fluorid...

Embodiment 3

[0042]1. Preparation of coating slurry for multi-walled carbon nanotubes: First, dissolve 2 g of sodium carboxymethyl cellulose in 198 g of deionized water, use a mechanical stirrer to stir at a rate of 700 rpm for 1 h until uniform, and configure to 1% The aqueous solution of sodium carboxymethyl cellulose with a content of 1%; 50g of multi-walled carbon nanotube aqueous conductive paste is added to the sodium carboxymethyl cellulose solution with a content of 1% (wherein the multi-walled carbon nanotube aqueous conductive paste is The content of carbon nanotubes is 3%, the diameter of multi-walled carbon nanotubes is 10-30nm, and the length is 30-50μm), using a mechanical stirrer to stir at a rate of 700 rpm for 1h until the multi-walled carbon nanotube slurry is evenly dispersed In a 1% sodium carboxymethyl cellulose solution, a multi-walled carbon nanotube coating slurry is prepared.

[0043] 2. Preparation of lithium cobaltate coating slurry: weigh 80g of lithium cobaltat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com