Cutting device and cutting method

A cutting device and wire cutting technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as large offset and increased time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

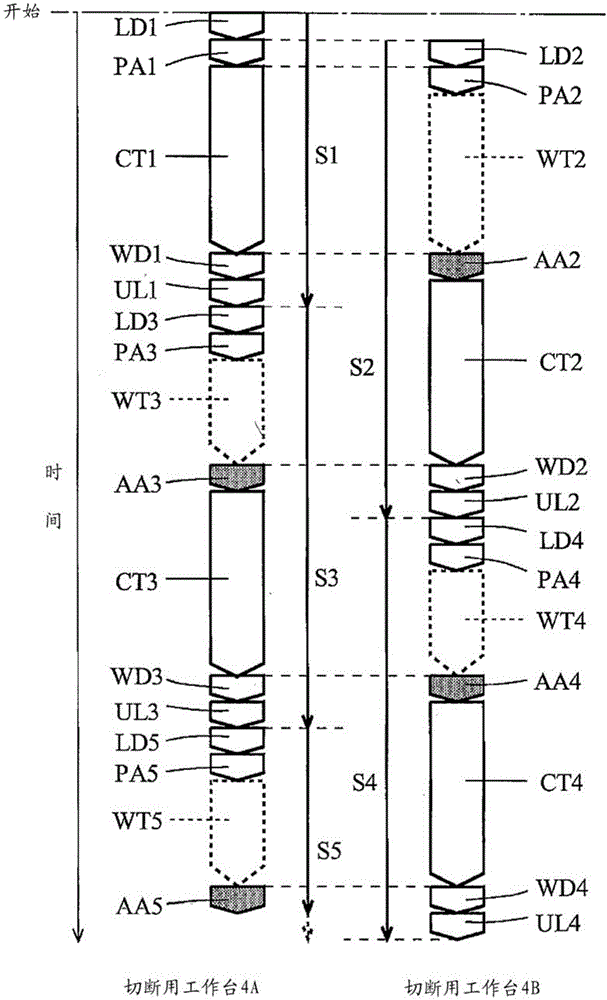

[0107] In the double-station type cutting device, the alignment mark is detected again before cutting the package substrate by using a camera for notch detection integrally provided on the spindle unit. In this way, the offset from the cutting line set by pre-alignment is corrected while the package substrate is shrunk, and the package substrate is cut along the corrected cutting line immediately before cutting.

[0108] refer to Figure 1 to Figure 5 , an embodiment of the cutting device according to the present invention will be described. Any one of the drawings in this application document is appropriately omitted or exaggerated for easy understanding and is schematically depicted. The same reference numerals are used for the same structural elements, and explanations thereof are appropriately omitted.

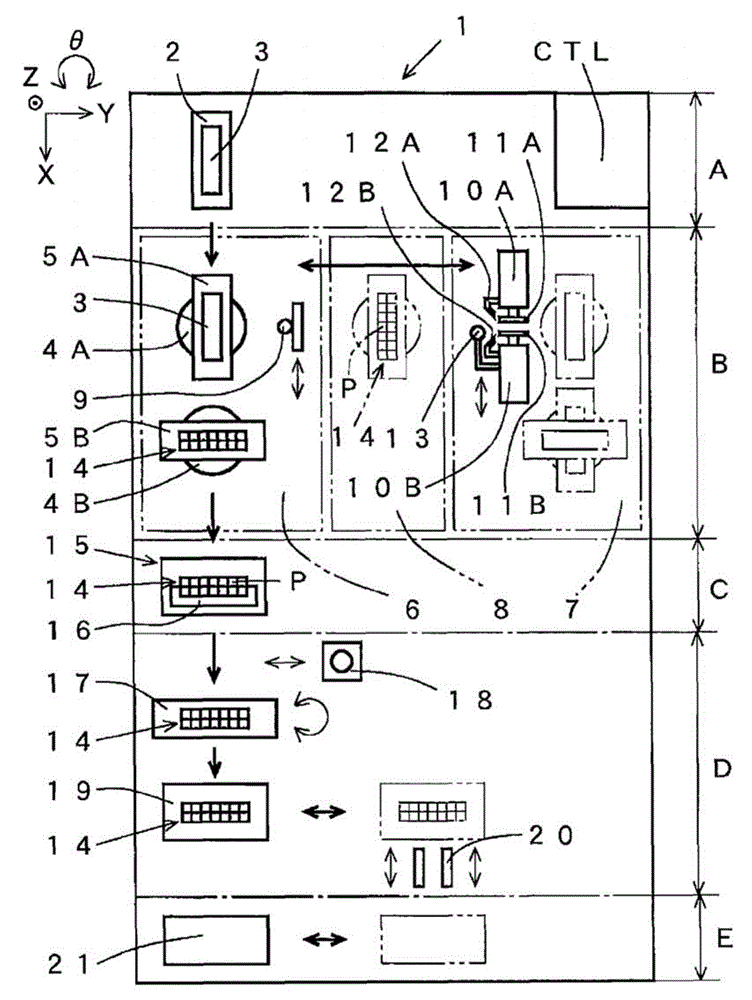

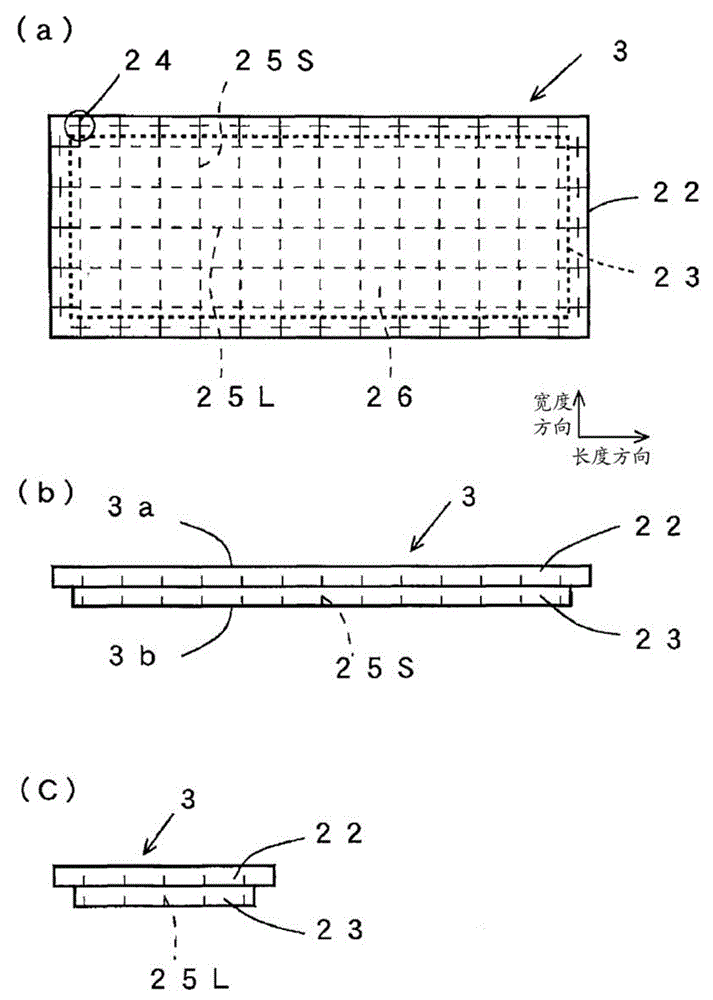

[0109] figure 1 It is a schematic plan view showing the double-station type cutting device 1 according to the present embodiment. The cutting device 1 singulates an ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com