Electronic device

A technology of electronic devices and electronic modules, which is applied in the direction of electrical digital data processing, instruments, cooling/ventilation/heating transformation, etc., can solve the problems of shortened working life, high working temperature, and inability to dissipate heat, so as to improve the heat dissipation effect and improve The effect of the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

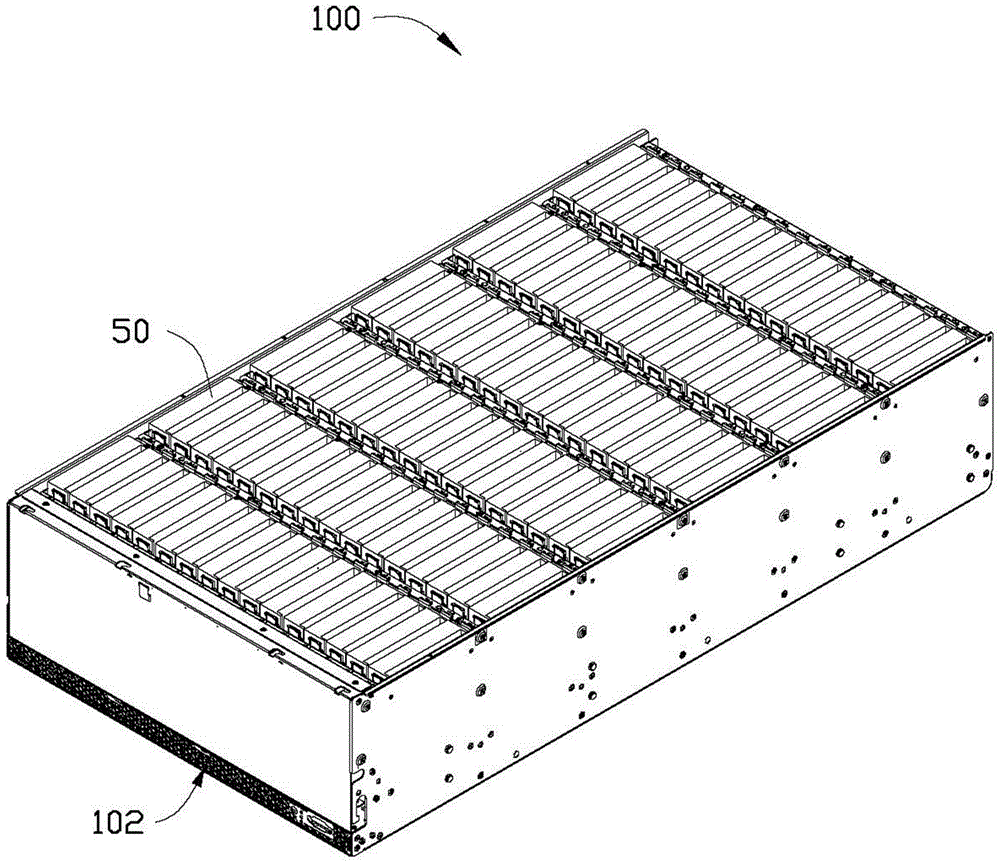

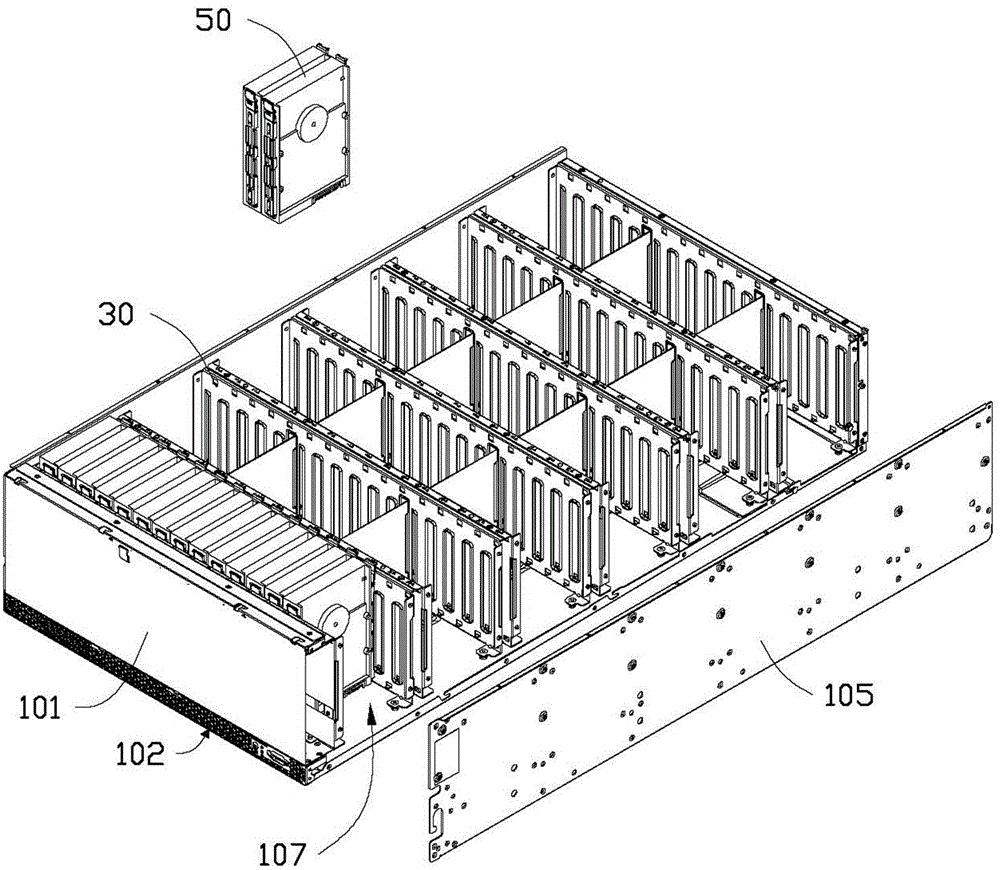

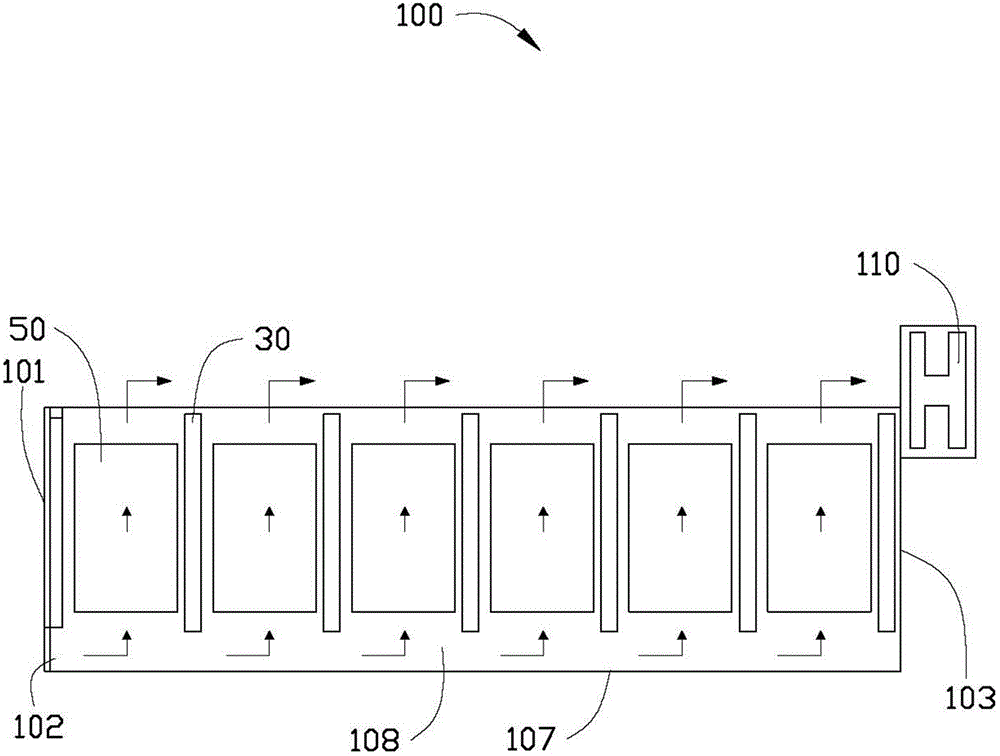

[0013] Please refer to figure 1 and figure 2 , The electronic device of the present invention includes a chassis 100 and several groups of electronic modules 50 , the chassis 100 includes a front panel 101 , a rear panel 103 , two side panels 105 , a bottom panel 107 and several partitions 30 . The partitions 30 are arranged in parallel between the front panel 101 and the rear panel 103 and vertically connected to the two side panels 105 respectively. The bottom of each partition 30 maintains a gap 108 with the bottom panel 107 . A cooling channel is formed between every two adjacent partitions 30 . Each group of electronic modules 50 is vertically inserted between two adjacent partitions 30 . An air inlet 102 is defined at the bottom of the front panel 101 . In this embodiment, the electronic module 50 is a hard disk module.

[0014] Please also refer to image 3 , when the electronic device of the present invention is working, the wind flow, such as external cold air, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com