Method for calibrating small-aperture diaphragm

A technology of small hole diaphragm and optical method, which is applied in the direction of using optical devices, measuring devices, instruments, etc., to achieve the effects of less human-subjective error factors, high measurement accuracy, and simple and easy-to-understand principles of the invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

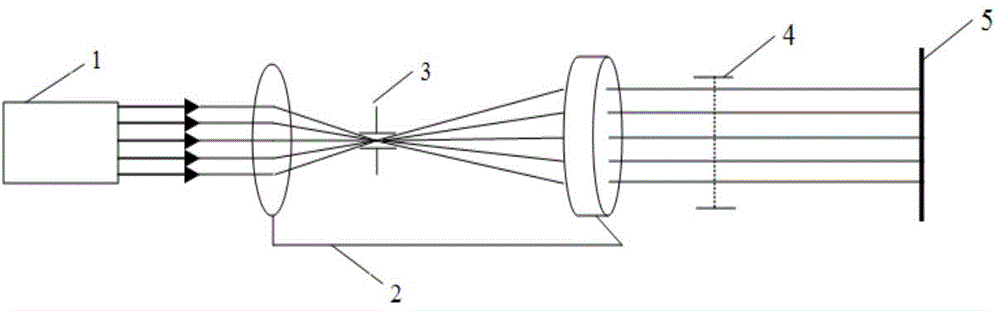

[0015] exist figure 1 Among them, the observation screen (5) is a reticle that can measure the size of the pattern. When the laser (1) passes through the collimated beam expander system (2), the size of the output parallel circular beam should be slightly larger than the diameter of the fixed aperture diaphragm (4). The diameter of the fixed aperture diaphragm (4) can be obtained by measuring the light spot.

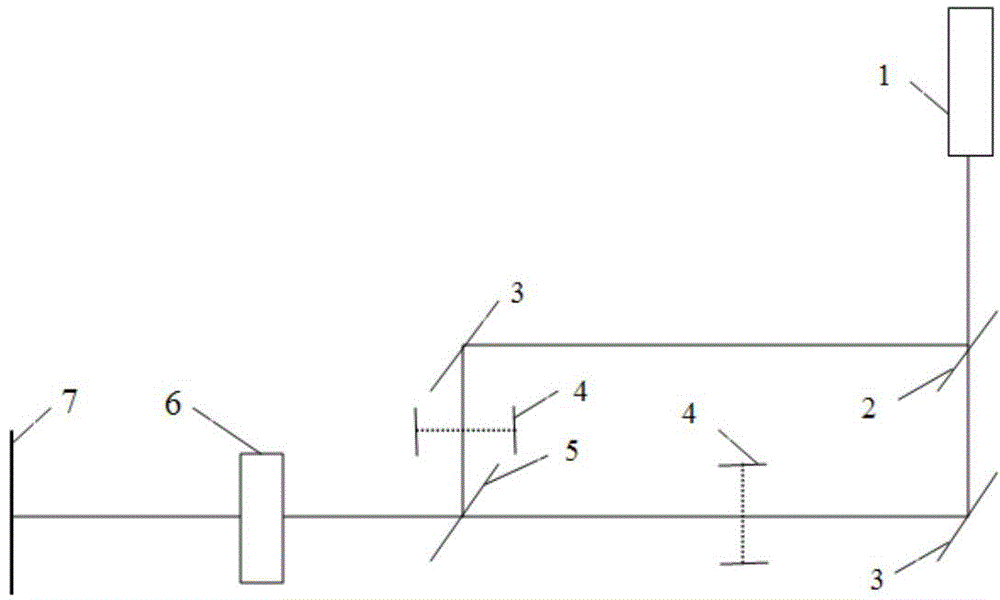

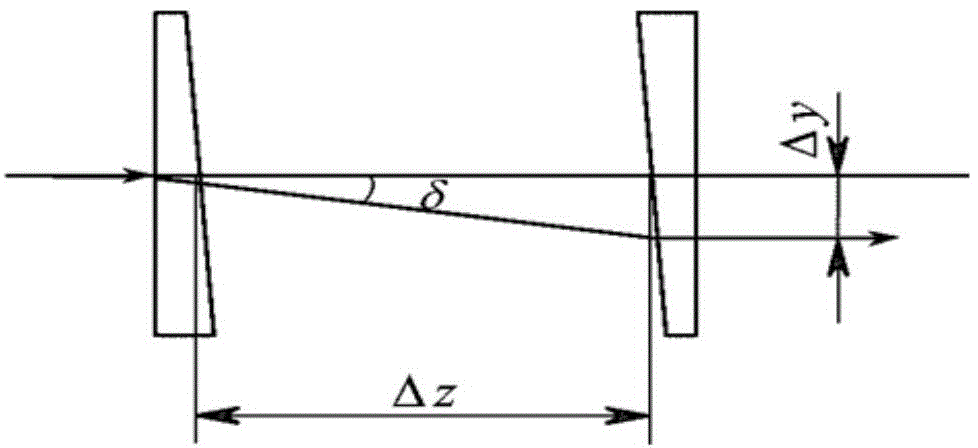

[0016] exist figure 2 Among them, the Mach-Zehnder interference system is composed of the beam splitter (2), the total mirror (3) and the beam combiner (5). A laser (1) is used as the input light source of the interference system, and a small hole aperture (4) of the same specification to be tested is respectively placed in any adjacent two arms of the interference system, and the actual diameters of the two apertures (4) are required to be consistent. Promptly require that two diaphragms (4) driving levers should be dialed to the same position. A double optical wed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com