Speed synchronous control method and system for load simulator

A technology of load simulator and synchronous control, applied in the direction of program control device, software simulation/interpretation/simulation, etc., can solve problems such as high cost and complex structure, and achieve the effect of avoiding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

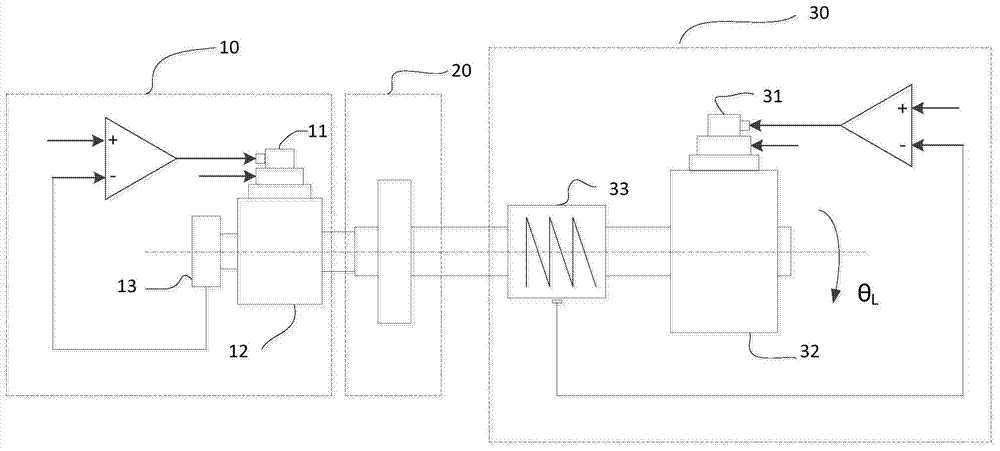

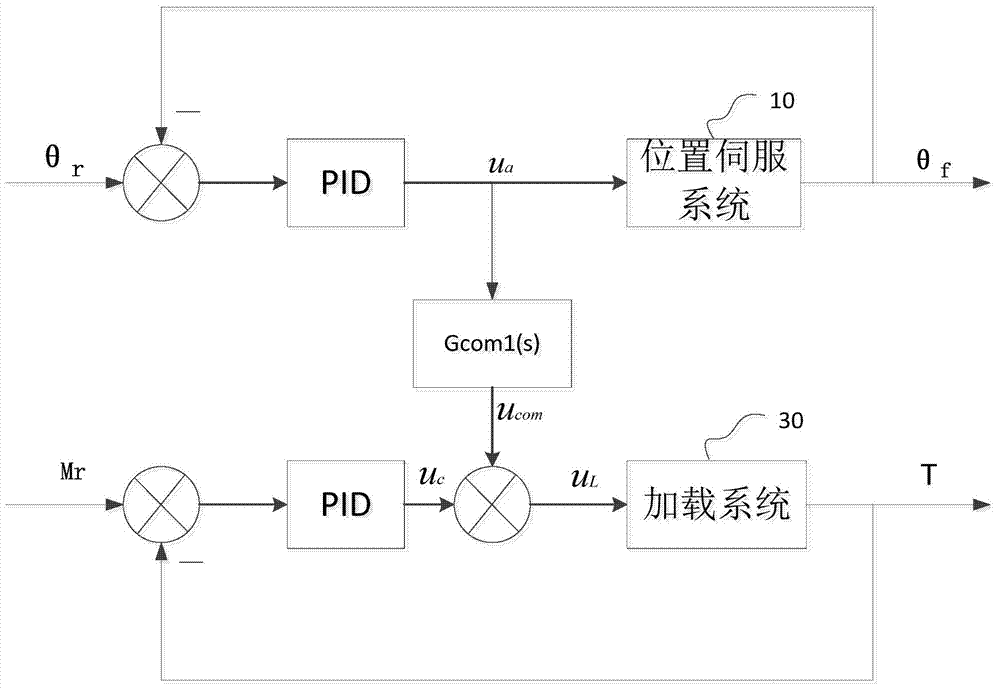

[0145] As an implementation manner, step S10 may include:

[0146] The servo valve 11 of the position servo system 10 controls the position hydraulic motor 12 to output a force or torque signal according to a control command.

[0147] Step S20 may include:

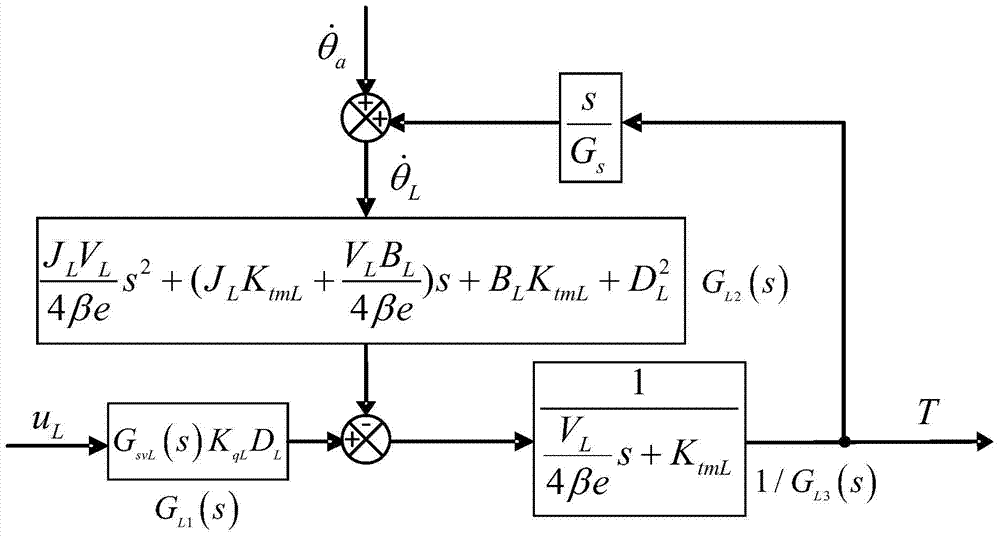

[0148] S21: The loading servo valve 31 of the loading system 30 controls the loading hydraulic motor 32 of the loading system 30 according to the current signal of the servo valve 11 of the measured position servo system, so that the force or moment output by the loading hydraulic motor 32 is applied to the object by the inertial load 20 Measuring position servo system 10.

[0149] As a preferred solution, step S20 may also include:

[0150] S211: The loading servo valve 31 controls the loading hydraulic motor 32 according to the pressure difference signal between the two chambers of the position system, so that the force or torque signal output by the loading hydraulic motor 32 is applied to the measured position servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com