Heat setting machine with intelligent control device

A heat-setting machine, intelligent control technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of affecting the heat-setting effect, unsmooth airflow, large air resistance, etc., to ensure heat-setting Effect, uniform and smooth airflow, the effect of reducing airflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

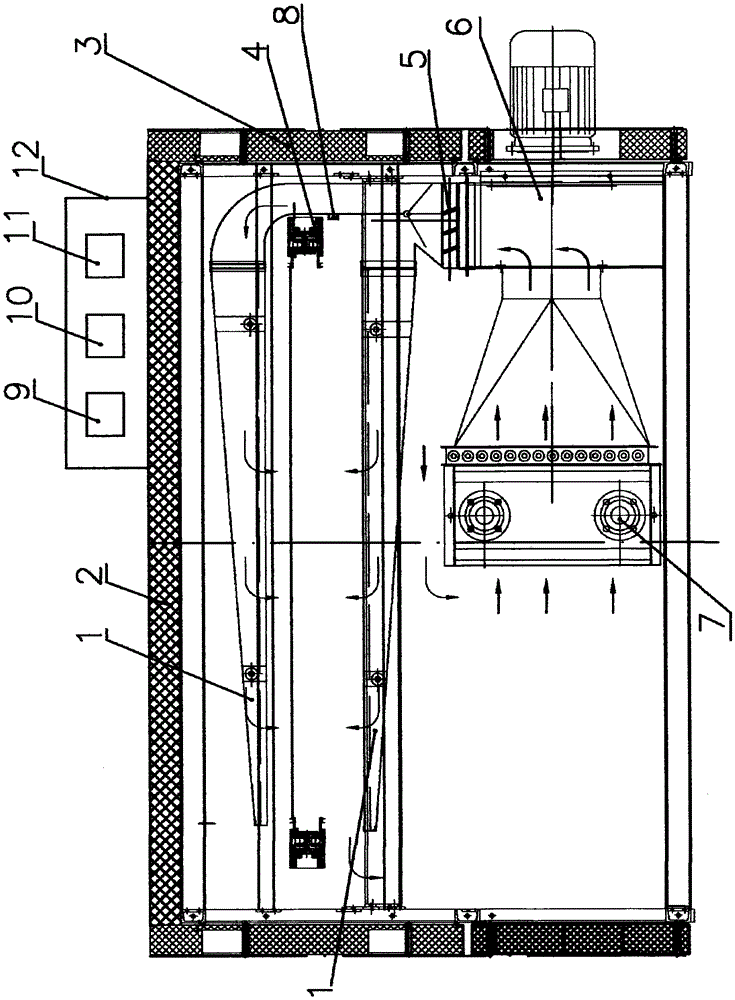

[0009] Such as figure 1 As shown, a heat-setting machine with an intelligent control device of the present invention includes an insulated box 2 and a hot air blowing device 1 located in the insulated box 2, the insulated box 2 is provided with an insulated door 3, The hot air blowing device 1 is connected with the deflector 5, the deflector 5 is connected with the air outlet of the blower fan 6, the air inlet of the blower blower 6 is connected with the natural gas heating system 7 in sequence, and the hot blast blowing device 1 has two one, respectively located above and below the needle plate 4, the inner wall of the insulated box 2 is provided with a temperature on-line detection sensor 8, the top of the insulated box 2 is provided with a temperature control device 12, in the temperature control device 12 Be provided with data analyzer 9, data processor 10, linkag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com