Preparation method of low-density carbon/carbon composite cylindrical material

A carbon composite and low-density technology, applied in the field of low-density carbon/carbon composite cylinder material preparation, can solve problems affecting performance and life, high cost, poor strength, etc., to improve material utilization, increase service life, The effect of enhancing the ability to resist external force and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

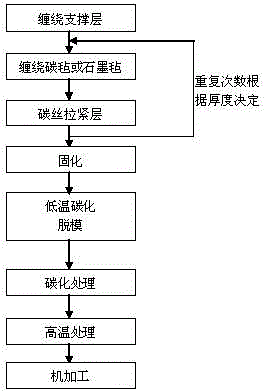

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Ordinary High Temperature Adhesives

[0024] Dissolve p-toluenesulfonic acid with industrial ethanol, wherein the weight ratio of industrial ethanol and p-toluenesulfonic acid is 100 parts: 12 parts, then stirred for 20 minutes, then gradually added 100 parts of phenolic resins and 6 parts of boric acid under stirring, and finally Add 80 parts of graphite into the solution, and continue stirring for 60 minutes to obtain a high-temperature binder.

[0025] The dimensions of the prepared low-density carbon / carbon composite cylinder are: D=1100mm, d=990mm, L=1800mm, and thickness 55mm.

[0026] A method for preparing a low-density carbon / carbon composite cylinder, the steps of which are

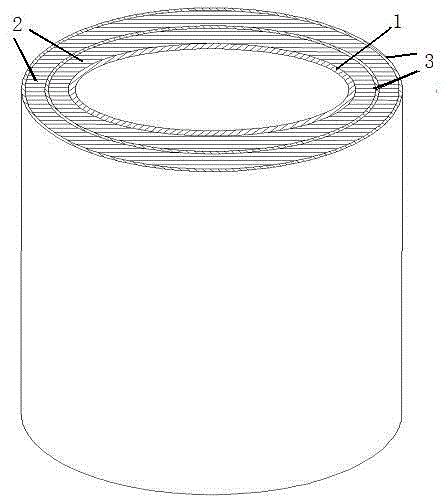

[0027] a. Prepreg carbon fiber cloth is used to prepare support layer 1, and the winding thickness is 3 mm;

[0028] b. Apply high-temperature adhesive on the support layer 1, wrap a layer of 12mm graphite felt on the support layer 1, pay attention to compressing when win...

Embodiment 2

[0037] The dimensions of the prepared low-density carbon / carbon composite tube are: D=596mm, d=460mm, L=1400mm, thickness 68mm:

[0038] a. The support layer 1 is prepared by winding prepreg carbon filaments, and the winding thickness is 3 mm;

[0039] b. Brush the high-temperature adhesive on the support layer 1, and then wrap the second layer of 10mm thick carbon felt on the support layer 1. When winding, the carbon felt is close to the support layer 1 and cannot be loosened. Use carbon rope to sew the interface;

[0040] c. On the basis of step b, use prepreg carbon wire to wrap the tension layer, the tension of the winding monofilament is 5N, and the winding thickness is 1mm;

[0041] d. On the tensioning layer 3 in step c, apply a high-temperature adhesive and wind carbon felt, the carbon felt is close to the tensioning layer 3, and the tensioning layer 3 is wrapped with carbon filaments with a thickness of 3 mm to form a preform;

[0042] e. Put the above preform into t...

Embodiment 3

[0048] The dimensions of the prepared low-density carbon / carbon composite tube are: D=1423mm, d=1260mm, L=1800mm, thickness 82mm:

[0049] a. The supporting layer is prepared by winding pre-preg carbon fiber cloth, and the winding thickness is 4mm;

[0050] b. Brush the high-temperature adhesive on the support layer 1, and then wrap a layer of 14mm thick carbon felt on the support layer 1. When winding, pay attention to compressing to ensure that the carbon felt is close to the support layer 1 and cannot be loosened. Use carbon rope to sew interface;

[0051] c. Wrap a layer of graphite paper on the basis of carbon felt in step b, with a thickness of 1mm;

[0052] d. On the basis of the graphite paper in step c, wrap the tension layer 3 with pre-impregnated carbon filaments, the tension of the winding monofilament is 5N, and the winding thickness is 1mm;

[0053] e. On the tension layer 3 in step d, apply a high-temperature adhesive again, and wrap 3 layers of graphite felt,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Winding thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com