A kind of preparation method of submarine artificial reef

A technology of artificial reef and sulphoaluminate cement, which is applied in the field of building materials, can solve the problems of raw material transportation, loading and unloading storage and construction, difficulty in adapting to the environmental conditions of islands and reefs, difficulty in raw material loading and unloading and storage, etc., and achieve good underwater Effects of anti-dispersion ability, reduced construction cost, good intermeshing and bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Submarine artificial reef made of ordinary Portland cement.

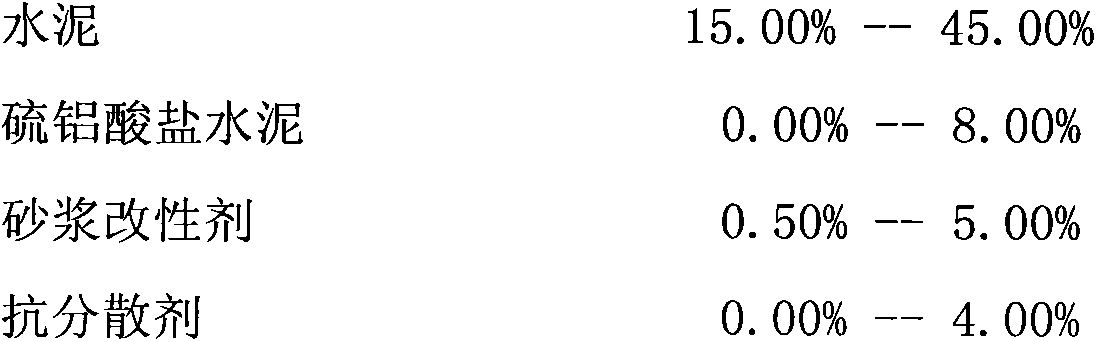

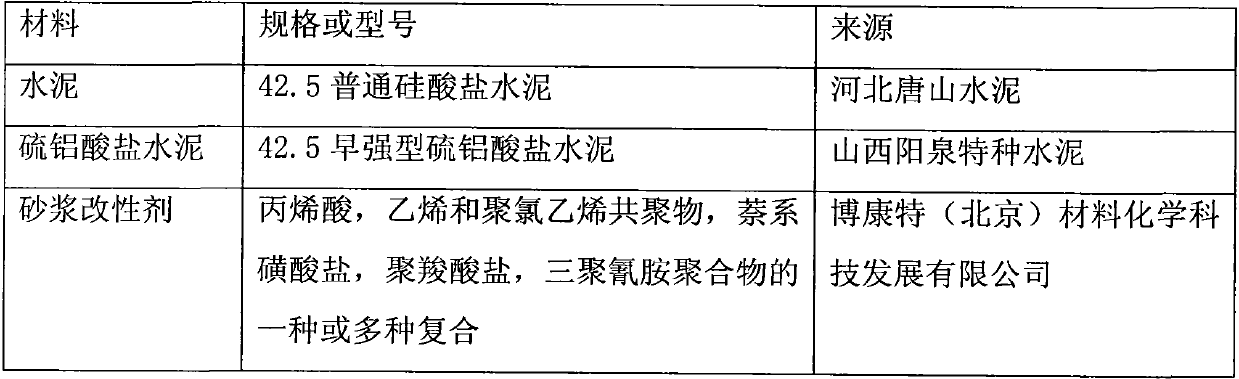

[0031] Table 1: Raw materials used

[0032]

[0033]

[0034] Submarine artificial reefs prepared with Portland cement:

[0035] 42.5 ordinary Portland cement 32.40%, 42.5 early strength sulfoaluminate cement 1.60%, mortar modifier 2.94%, anti-dispersion agent 0.02%, silica fume 1.87%, fly ash 5.10%, slag 2.37%, bone Material 38.30%, seawater 15.40%,. After accurately weighing the raw materials according to the proportion, stir with a mortar mixer, add sea water while stirring, after stirring for 5-10 minutes, stop the machine for 1-3 minutes, continue stirring for 1-2 minutes, pour the stirred mortar into the In a 4cmx4cmx16cm mold with a depth of 20cm in water, take out the test mold from the water after 6 hours, scrape the surface of the mold with a scraper, put it in water again for 24 hours, and measure the compressive strength of the mortar for 1 day after removing the mold, and other test piece...

Embodiment 2

[0038] Seabed artificial reefs prepared with slag cement.

[0039] Table 2: Raw materials used

[0040]

[0041] Seabed artificial reefs prepared with slag cement:

[0042] 42.5 slag cement 35.20%, 42.5 early strength sulfoaluminate cement 2.10%, mortar modifier 2.72%, anti-dispersion agent 0.03%, silica fume 2.36%, fly ash 6.89%, aggregate 37.10%, seawater 13.60% . After accurately weighing the raw materials according to the proportion, stir with a mortar mixer, add sea water while stirring, after stirring for 5-10 minutes, stop the machine for 1-3 minutes, continue stirring for 1-2 minutes, pour the stirred mortar into the In a 4cm x 4cm x 16cm mold with a depth of 20cm in water, take out the test mold from the water after 6 hours, scrape the surface of the mold with a scraper, put it back into the water and maintain it for 24 hours, and measure the compressive strength of the mortar for 1 day after the mold is removed. The blocks were maintained in seawater at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com