Underwater non-dispersible concrete and its preparation method

A concrete and dispersion technology, applied in the field of concrete, can solve the problems that concrete does not meet the technical requirements of underwater engineering, loses the ability of aggregate cementation, and is difficult to guarantee the engineering quality, and achieves good underwater anti-dispersion performance and good anti-dispersion performance. , the effect of improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

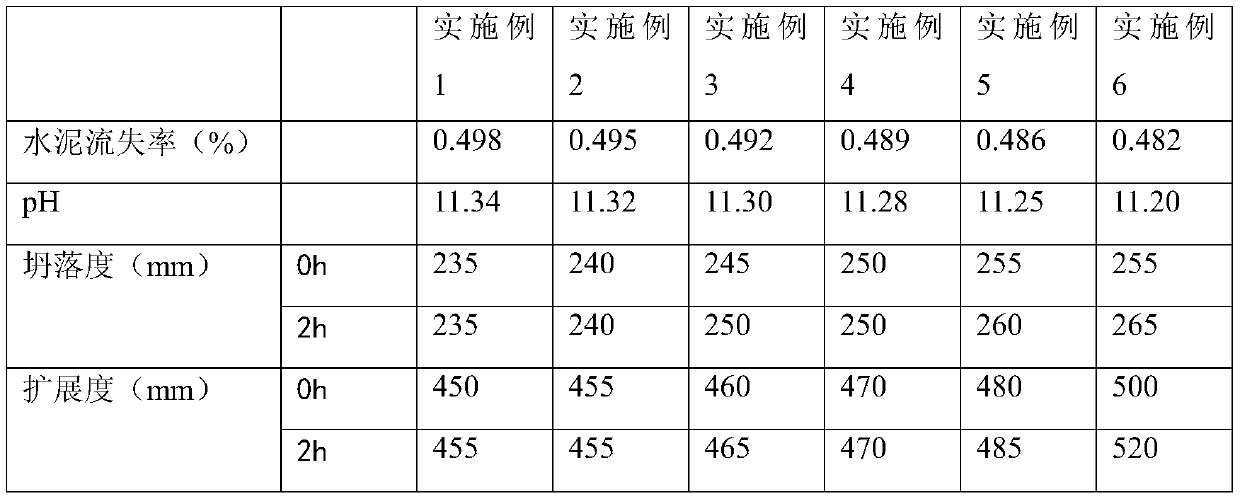

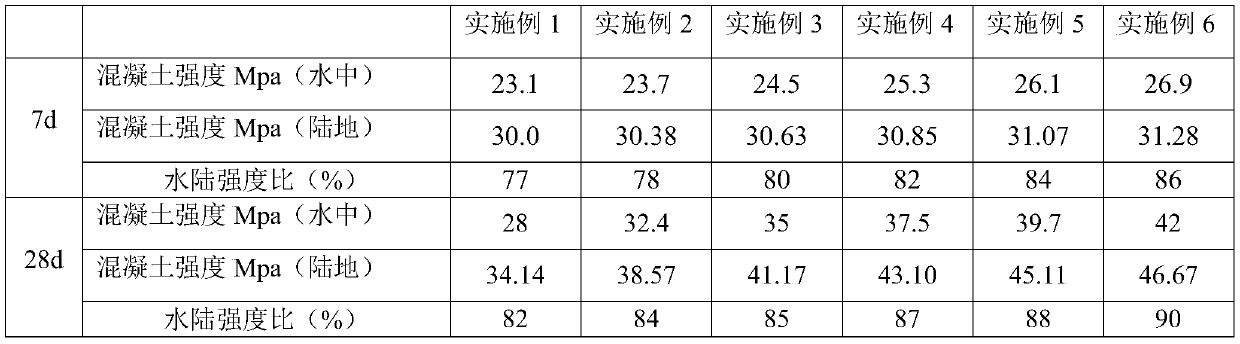

Embodiment 1 to Embodiment 6

[0025] Embodiment 1 to embodiment 6: the specific materials are selected as follows: cement is ordinary Portland cement, strength grade 42.5, purchased from Tangshan Jidong Sanyou Company; Hebei Zunhua river sand, fineness modulus 2.6; Hebei Tangshan 7- 18mm continuous graded gravel.

[0026] The flocculant is carboxymethyl cellulose, selected from Renqiu Chengyi Chemical; the early strength agent includes sodium chloride and triethanolamine, wherein triethanolamine is selected from Shijiazhuang Haisen Chemical Co., Ltd., and sodium chloride is selected from Beijing Qingkaihua Feng Technology Development Co., Ltd.; auxiliary agents include fatty alcohol polyoxyethylene ether sodium sulfate and nano silicon powder, wherein fatty alcohol polyoxyethylene ether sodium sulfate is selected from Zhengzhou Shengtai Chemical Co., Ltd.

[0027] The selected nano-silicon powder is purchased from the market, and its main technical indicators include: a specific surface area of 640±50, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com