Main rib conveying mechanism for roll welding processing of square pipe steel reinforcement framework

A steel skeleton and transmission mechanism technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail:

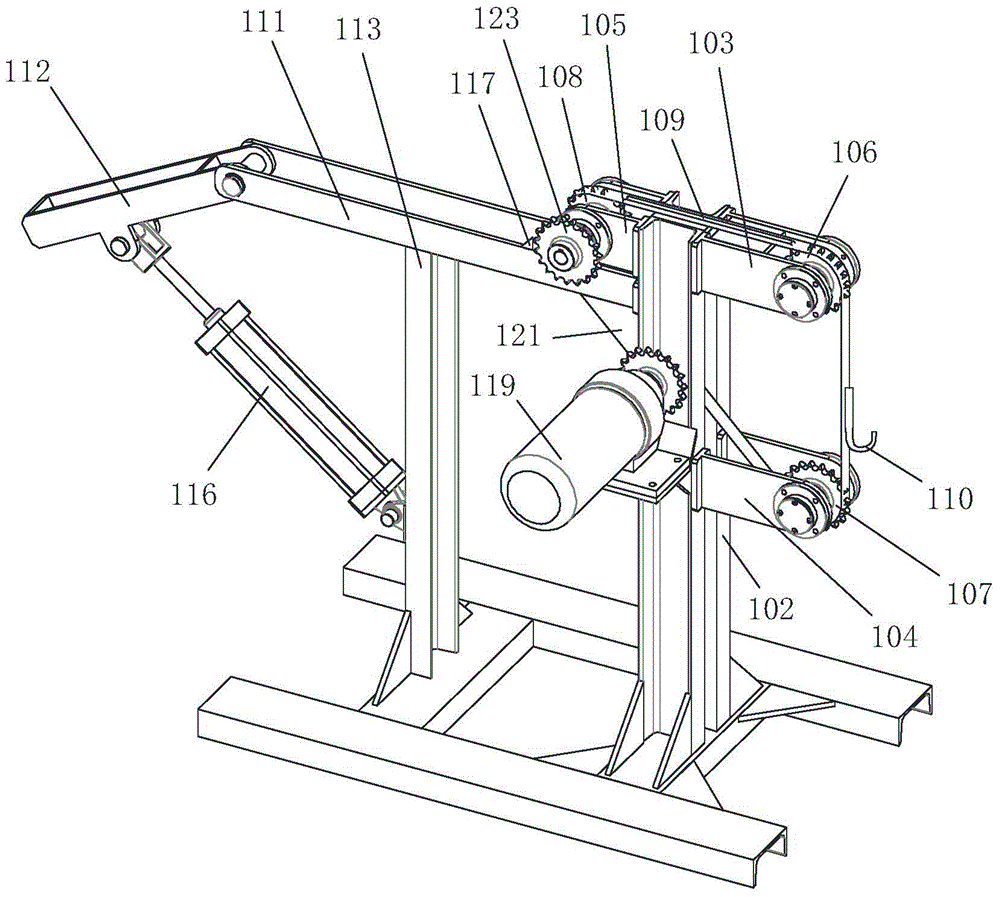

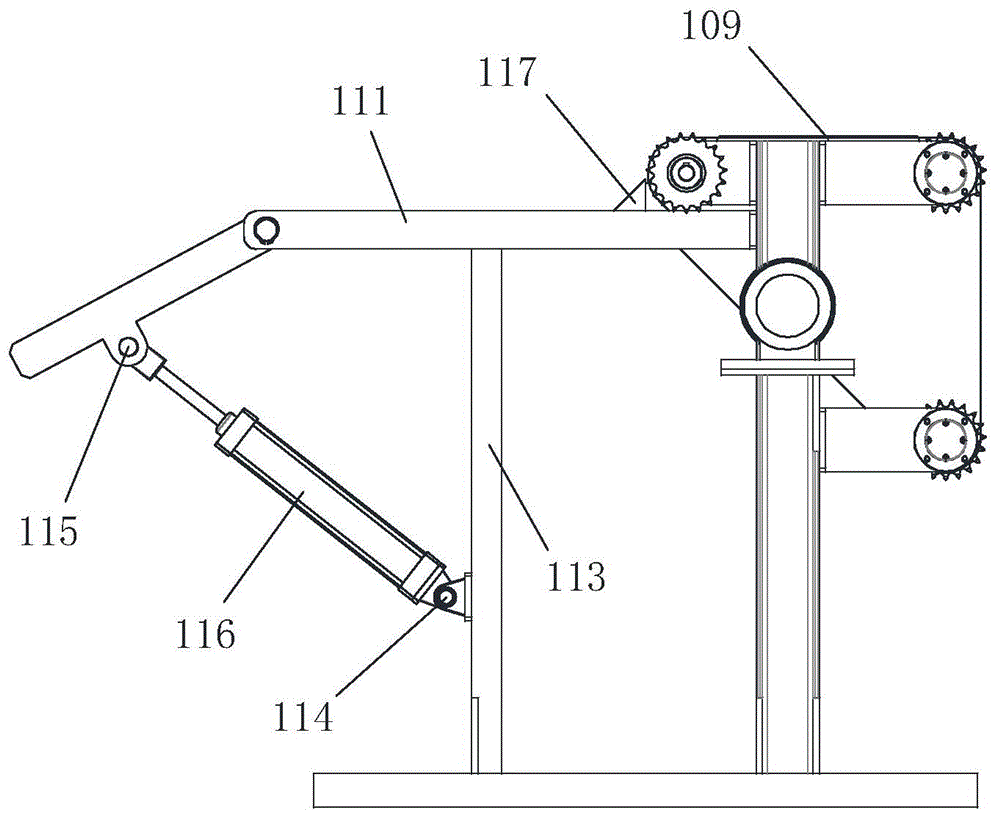

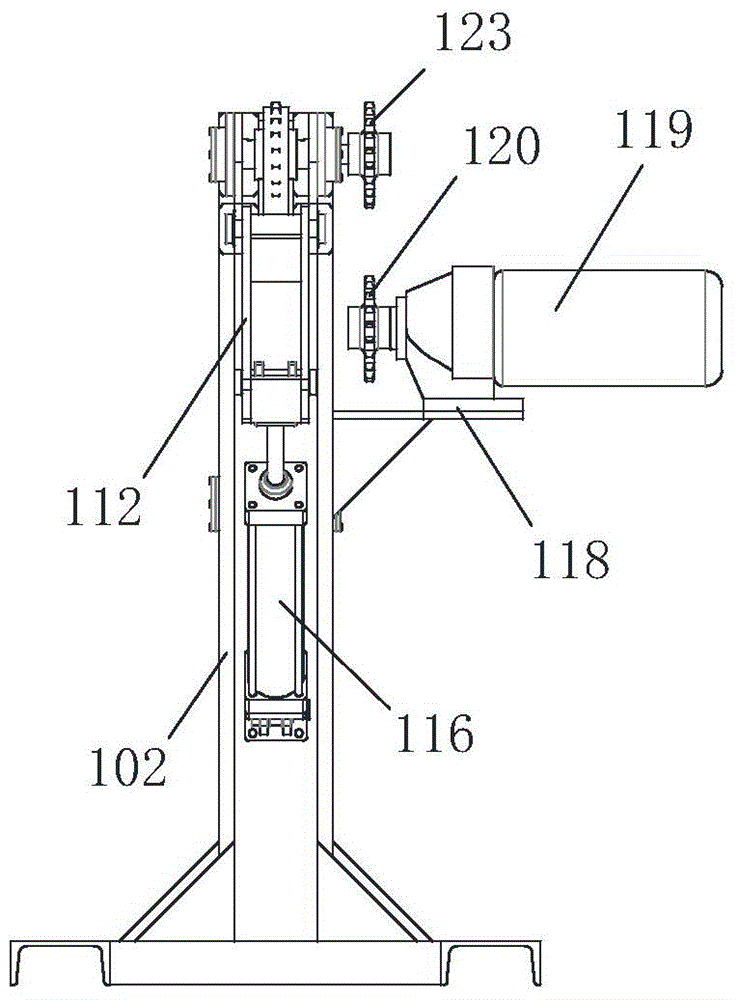

[0024] combine Figure 1 to Figure 5 As shown, the steel bar handling device 1 is suitable for transporting the polished steel bar to the steel bar blanking conveying device, so as to prepare for the subsequent seam welding process. One side of the steel bar handling device is provided with a polished steel bar conveying device 2, and the polished steel bar conveying device is placed with polished steel bars; In front of the seam welding machine, the grinding steel bar conveying device and the steel bar blanking conveying device are all arranged along the direction of the steel bar.

[0025] The steel bar handling device 1 includes at least two handling units 101, and each handling unit is arranged in a line in the direction of the reinforcement; the handling unit includes a mounting bracket 102, and the mounting bracket is vertically arranged, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com