Density board and manufacture method thereof

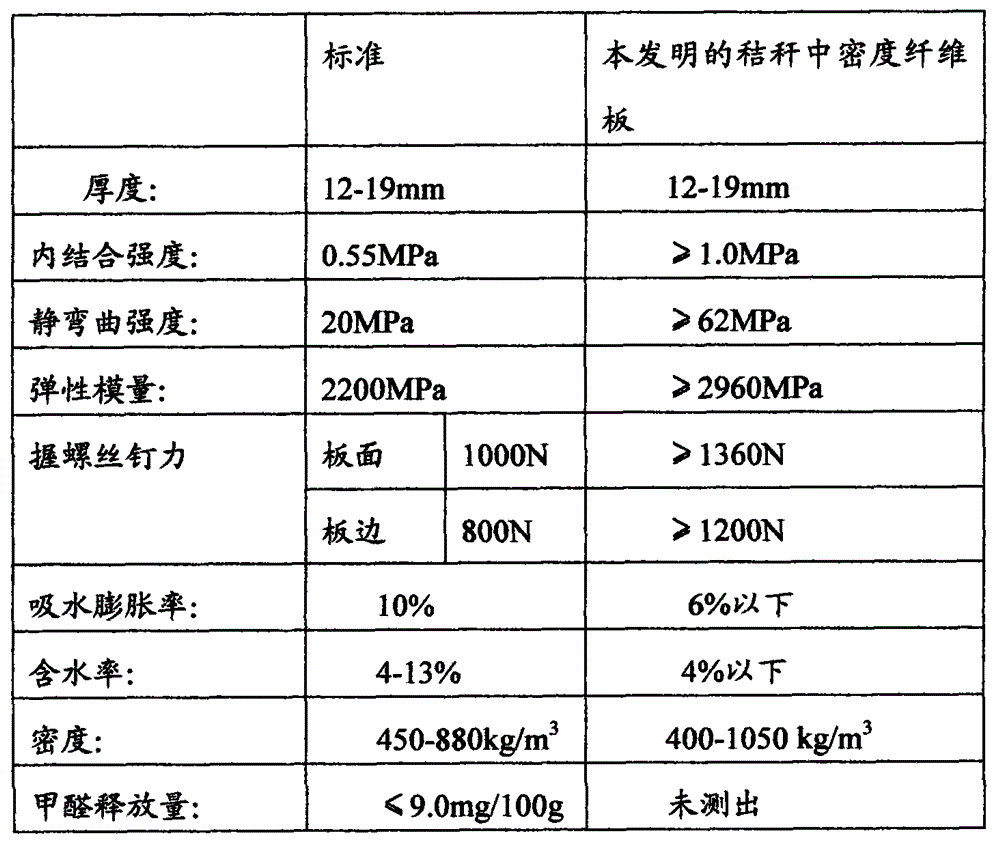

A density board and isocyanate technology, applied in the field of building materials, can solve problems such as unreasonable raw materials and fleece pollution, and achieve the effects of eliminating formaldehyde release, enhancing adhesion, board strength and internal bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] At the same time, the embodiment of the present invention also proposes a method for preparing any of the aforementioned density boards, including:

[0019] fully mixing the straw fiber and isocyanate, and vacuum dehydrating and drying, so that the moisture content of the mixture is 5-15%;

[0020] After the raw materials are paved and formed by external demoulding, they are pre-pressed at a pressure of 0.5-2.5 MPa;

[0021] Then adjust the pressure to 2-6MPa, and perform hot pressing at a temperature of 150-230°C;

[0022] After demoulding, it is processed to obtain the finished product.

[0023] Wherein, the processing includes: cutting and sanding. The pre-pressing time is 20-120 seconds. The time for the hot pressing is 100-250 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com