Preparation method of Silicalite-1/ZSM-5 composite molecular sieve

A ZSM-5, composite molecular sieve technology, used in molecular sieve catalysts, microsphere preparation, chemical instruments and methods, etc., can solve the uncontrollable thickness of composite molecular sieve shell structure, adverse reactions, and reduce composite molecular sieve catalytic effect and type selection effect. and other problems, to achieve the effect of being conducive to large-scale production and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Disperse 50 grams of ZSM-5 molecular sieve evenly in water under the ultrasonic frequency of 40KHz and ultrasonic power of 360W. Under the condition of water bath temperature of 25°C, adjust the pH value to 9 with ammonia water, and add template agent tetrapropyl bromide ammonium chloride, and then ethyl tetrasilicate was added, and the resulting mixture was reacted for 4 hours at a stirring speed of 200 rpm, separated, and dried at a temperature of 80°C to obtain a pretreated ZSM-5 molecular sieve Z1.

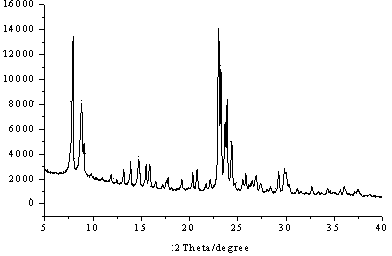

[0031] The particle size of ZSM-5 molecular sieve is 500nm; the silica / alumina molecular molar ratio is 27; the mass ratio of ethyl orthosilicate (calculated as silica) to ZSM-5 molecular sieve is 0.2; template agent (template agent TPA + The mass ratio of ZSM-5 to pretreated ZSM-5 is 1.5; the XRD diffraction pattern of ZSM-5 molecular sieve is shown in figure 2 .

Embodiment 2

[0033] Disperse 50 grams of ZSM-5 molecular sieve evenly in water under the ultrasonic frequency of 60KHz and ultrasonic power of 800W. Under the condition of water bath temperature of 55°C, adjust the pH value to 5 with sulfuric acid, and add the template agent tetrapropyl hydrogen ammonium oxide, and then ethyl tetrasilicate was added, and the resulting mixture was reacted at a stirring speed of 300 rpm for 4 hours, separated, and dried at 60°C to obtain a pretreated ZSM-5 molecular sieve Z2.

[0034] The particle size of ZSM-5 molecular sieve is 800nm; the silica / alumina molecular molar ratio is 76; the mass ratio of tetraethyl orthosilicate (calculated as silica) to ZSM-5 molecular sieve is 0.35; template agent (template agent TPA + Count) and the mass ratio of pretreatment ZSM-5 is 2.

Embodiment 3

[0036] Disperse 40 grams of ZSM-5 molecular sieve evenly in water under the action of ultrasonic frequency of 40KHz and power of 2000W. Under the condition of water bath temperature of 75°C, adjust the pH value to 12 with ammonia water, and add template agent tetrapropyl bromide ammonium chloride, and then methyl orthosilicate was added, and the resulting mixture was reacted for 3.5 hours at a stirring speed of 250 rpm, separated, and dried at a temperature of 100°C to obtain a pretreated ZSM-5 molecular sieve Z3.

[0037]The particle size of ZSM-5 molecular sieve is 300nm; the silica / alumina molecular molar ratio is 150; the mass ratio of methyl orthosilicate (calculated as silica) to ZSM-5 molecular sieve is 0.6; template agent (template agent TPA + Count) to the mass ratio of pretreated ZSM-5 is 0.5.

[0038] Synthesis of Composite Molecular Sieves

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com