Antitoxic fibers and fibrous media and methods for manufacturing same

An anti-toxin and medium technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of increasing the amount and toxicity of leaching, increasing immersion steps, increasing the overall cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Example 1 - Preparation of triiodide solution for mixing into impregnation solution

[0083] A. Preparation of 1N iodine (129600ppm I 2 ):

[0084] 1. In a 1L volumetric flask, add about 250mL of high-purity water

[0085] 2. Weigh out 175 g of KI solids and add to a 1 L flask containing water

[0086] 3. Vortex the solution in the flask to dissolve all the KI

[0087] 4. Weigh out 130 g of iodine solid and add to 1 L flask containing KI and aqueous solution

[0088] 5. Fill the volumetric flask to the mark line with high-purity water

[0089] 6. Add a magnetic stir bar to the flask

[0090] 7. Cap the flask with a glass stopper

[0091] 8. Cut a piece of parafilm and wrap it around the top of the flask / cork to prevent any leaks

[0092] 9. Pick up the flask and place it on the magnetic stir plate

[0093] 10. Set agitation control to 7 and allow the solution to mix overnight to dissolve all iodine solids

[0094] 11. Dilute as needed

Embodiment 2

[0095] Example 2 - Example of Antitoxin Fiber Medium

[0096] In one example, a sample amount (18.0 g) of an antitoxin fibrous medium of iodine-containing polyolefin was formed by the method of the invention comprising impregnating the starting polyolefin in a concentrated solution of triiodide at about 8500 ppm middle. The water content was approximately 2.5% by weight, therefore, after drying, approximately 17.10 g of dry antitoxin medium was produced. The % of total impregnated material added to the untreated sample was measured to be about 1.6% or 0.274 g by weight of the dry media. The antitoxin (iodine) was measured to be about 0.248 g or about 1.45% by weight of the dry antitoxin medium. Added chemical components were about 0.038 g.

[0097]A second sample amount (18.0 g) of iodine-containing polyolefin antitoxin fiber medium was prepared according to the same method as sample one. The initial water content prior to drying was approximately 5.0% of the initial wei...

Embodiment 3

[0098] Example 3 - Example of a mask

[0099] Face masks are formed using the antitoxin fibrous media of the present invention.

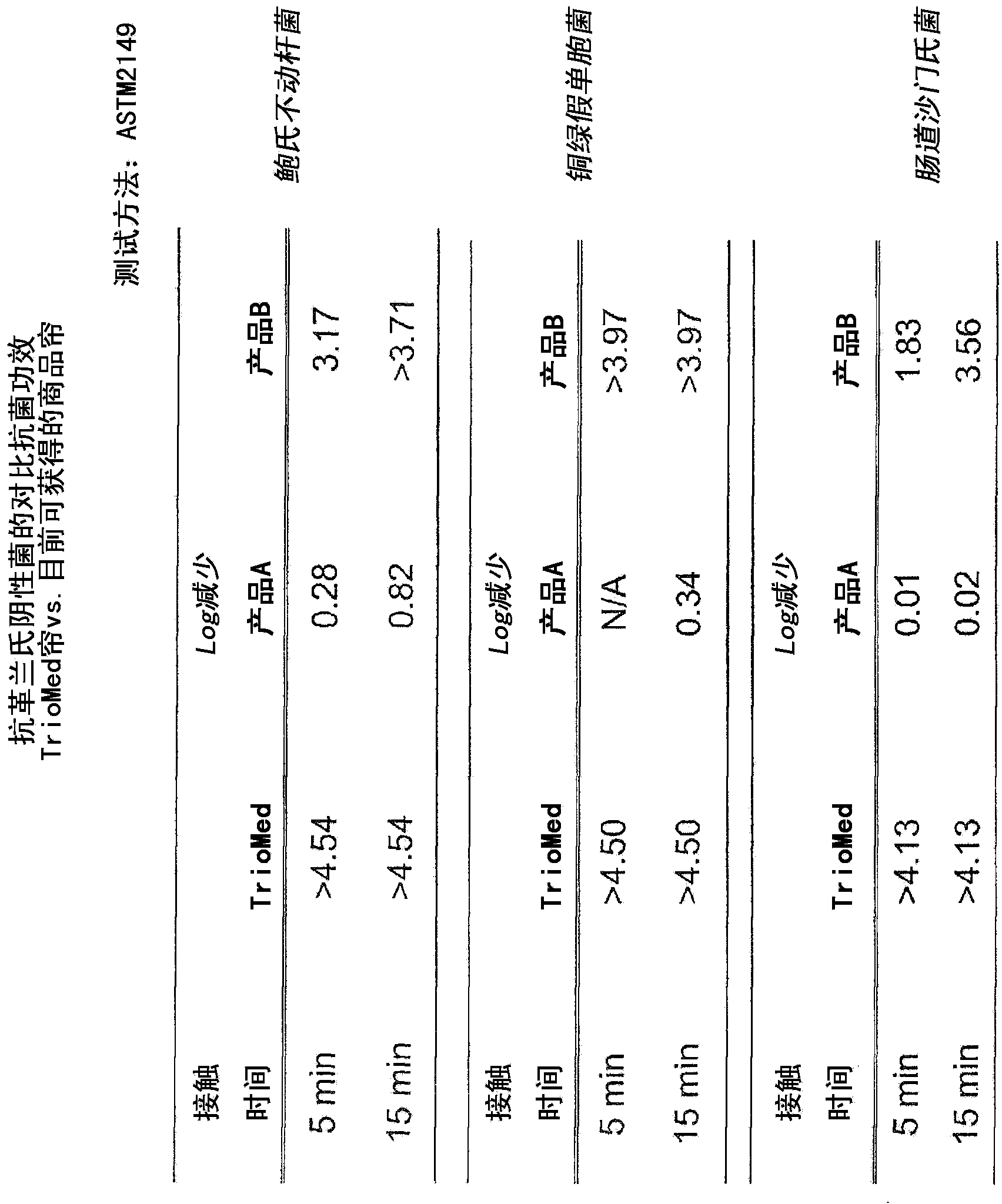

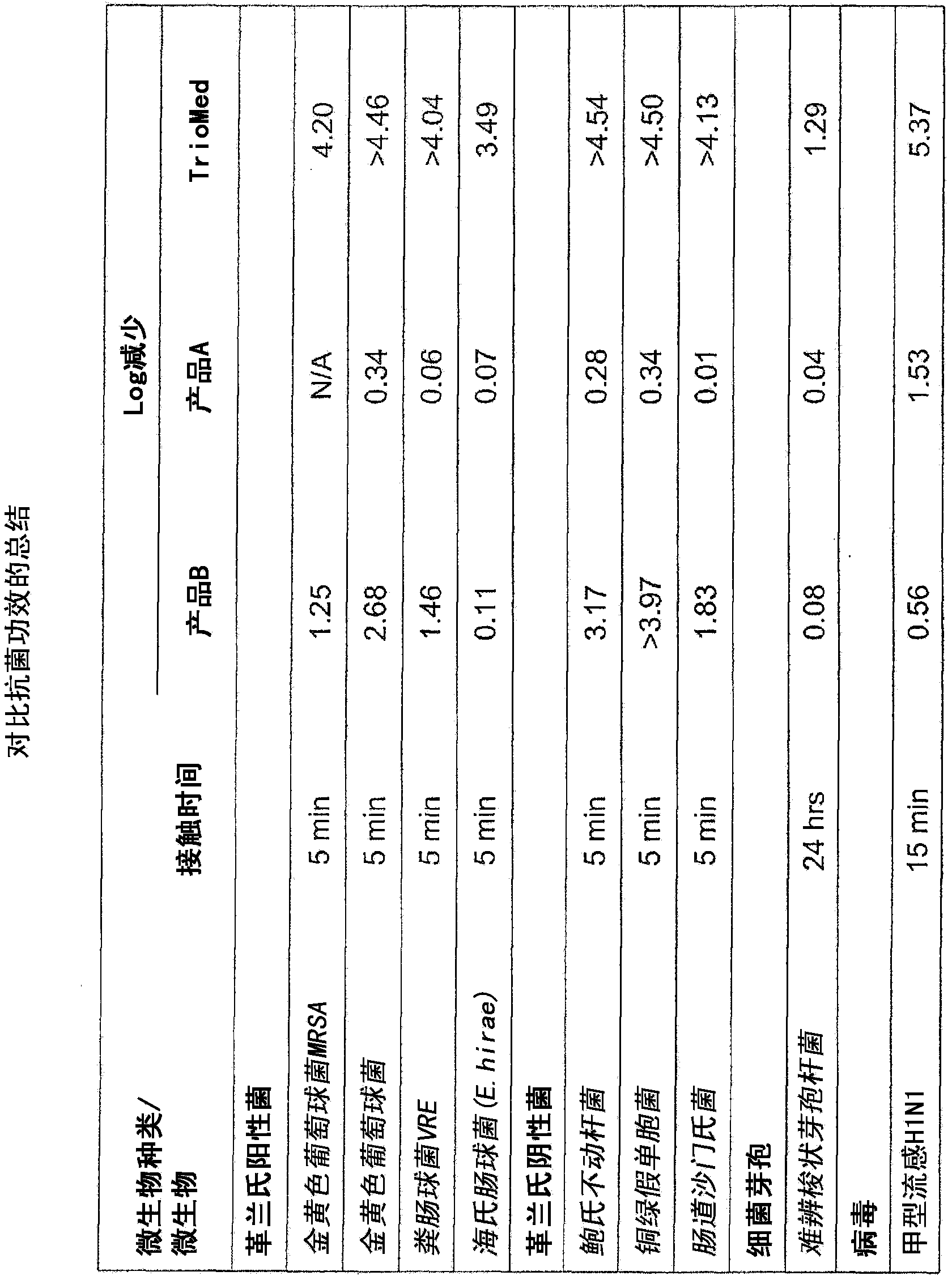

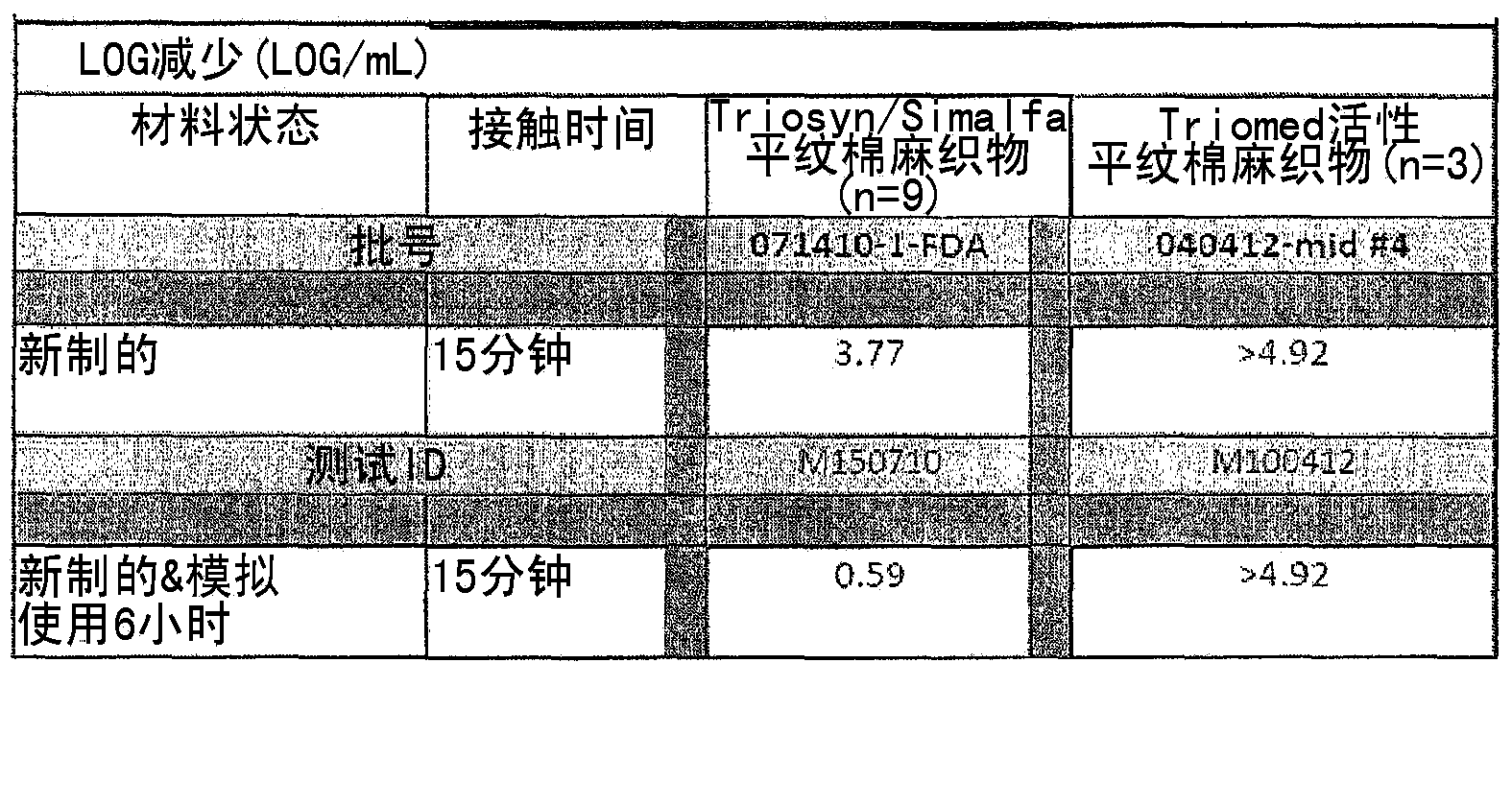

[0100] refer to image 3 , treating a fibrous layer for a mask with a triiodide impregnating solution prepared according to the method of the present invention. The resulting fibrous medium was used to make scrim layers for face masks. In the figures, the scrim is referred to as TrioMed active scrim, while the prior art scrim is referred to as Triosyn / Simalfa. TrioMed Active Scrim contains 0.4 grams per square meter (GSM) of iodine. Triosyn / Simalfa scrim contains 2.0 GSM of iodine.

[0101] The bactericidal efficacy of these covers was tested by incubating each test cover for 15 minutes with a known amount of Pseudomonas aeruginosa. The number of remaining viable bacteria was then quantified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com