End pressure type coaxial load

A coaxial load and coaxial technology, used in electrical components, circuits, waveguide devices, etc., can solve the problems of increasing signal transmission distance, deformation of large insulators, low signal transmission efficiency, etc. Effects of Burratio, Good Index and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

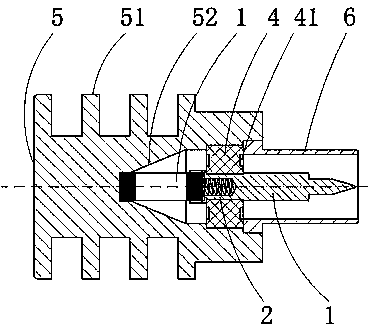

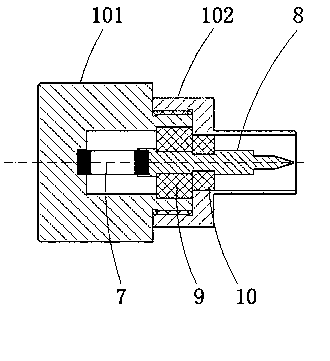

[0016] Example: Combined figure 1 , the end-pressure coaxial load of this embodiment includes: it includes a columnar resistor 1 that realizes the conversion of microwave power to heat energy of the product, a compression spring 2 that can still be in good contact after long-term use of the product, an inner conductor 3, and supports Functional insulating medium 4, outer conductor 5 to realize product grounding and heat dissipation, and end face bushing 6;

[0017] figure 1 As shown, a heat sink 51 is arranged on the outer circumference of the outer conductor 5 to improve the power carrying capacity of the product; a coaxial tapered transmission cavity 52 is arranged inside the outer conductor 5 to realize the gradual transition of signal transmission and reduce the reflection ratio of the signal, thereby reducing The voltage standing wave ratio of the product realizes high-efficiency signal transmission; the impedance compensation ring 41 provided on both sides of the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com