Strained sigesn fin photodetector

A photodetector, fin-type technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as deterioration of material quality and thermal stability, difficulty in preparing high-quality GeSn, and difficulty in wide-ranging band gap adjustment. To achieve the effect of low material, low cost, and improved adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

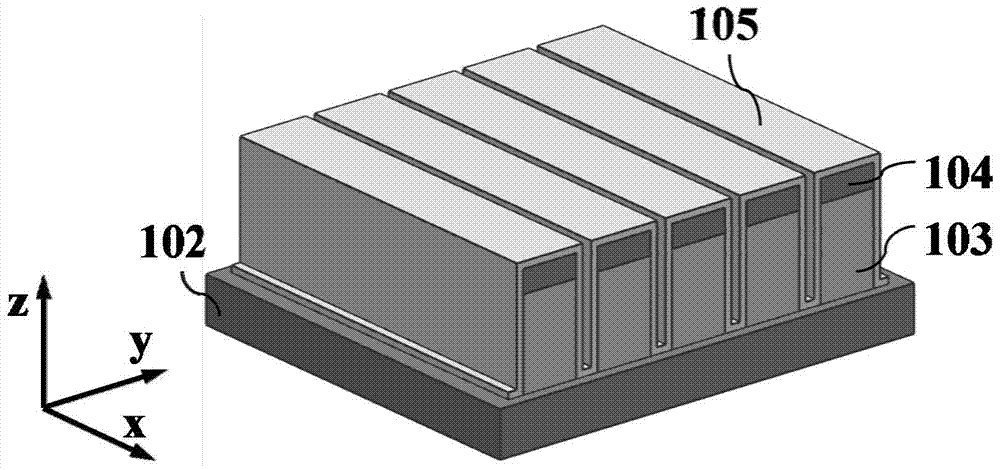

[0024] Embodiment 1, the strained SiGeSn fin photodetector of double-layer structure absorption region, single-layer structure stress layer

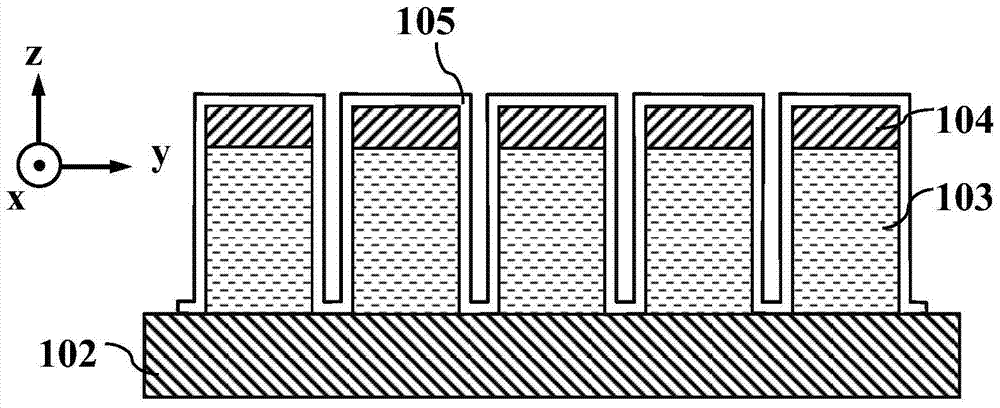

[0025] refer to figure 1 , this example includes from bottom to top: a lower electrode 102 , an absorption region 103 and an upper electrode 104 . The lower electrode 102 is made of a relaxed n-type Ge material, the upper electrode 104 is made of a relaxed p-type Ge material, and the absorption region 103 is made of a double-layer relaxed intrinsic SiGeSn composite material, which is arranged alternately with the gaps to form a fin structure; The upper electrode 104 is located on the upper surface of the absorption region 103 and has the same shape as the fin shape of the absorption region 103 . The surface of the upper electrode 104 and part of the sides of the absorption region 103 are wrapped with a single layer of Si 3 N 4 stress film 105, such as image 3 shown. Stress is generated in the absorption region 103 through the stres...

Embodiment 2

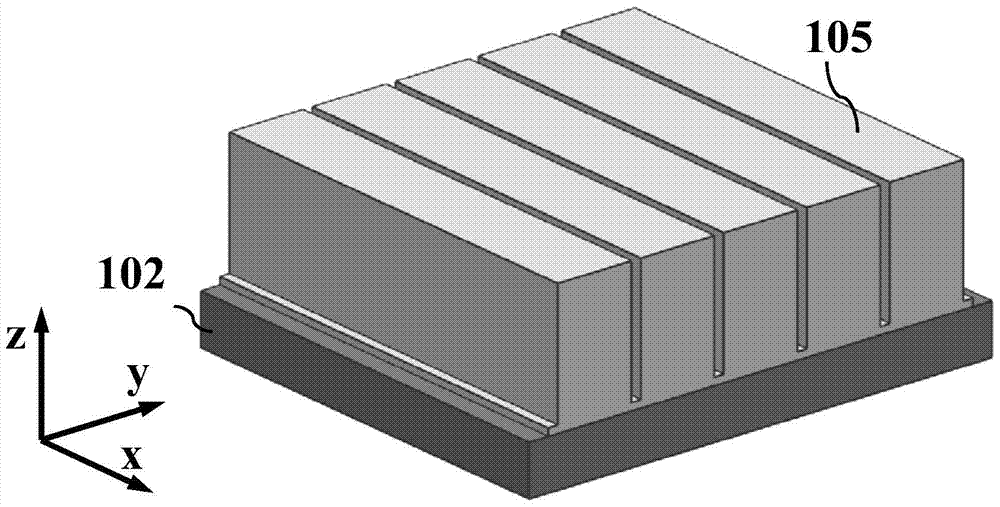

[0027] Example 2, a strained SiGeSn fin photodetector with a single-layer structure absorption region and a double-layer structure stress layer.

[0028] refer to figure 2 , this example includes from bottom to top: a lower electrode 102 , an absorption region 103 , an upper electrode 104 and a double-layer stress film 105 . The lower electrode 102 is made of a relaxed n-type Si material; the absorption region 103 is located on the lower electrode 102, and the absorption region 103 is made of a single-layer relaxed intrinsic SiGeSn composite material, and is arranged alternately with the gaps to form a fin structure; The upper electrode 104 is made of a relaxed p-type Si material, located on the upper surface of the absorption region 103, and its shape is the same as the fin shape of the absorption region 103; the double-layer stress film 105 completely wraps the sides of the upper electrode 104 and the absorption region 103, so that Stress is generated in the absorption reg...

Embodiment 3

[0031] Embodiment 3, single-layer structure absorption region, strained SiGeSn fin photodetector of single-layer structure stress layer

[0032] refer to figure 1 , this example includes from bottom to top: a lower electrode 102 , an absorption region 103 and an upper electrode 104 . The lower electrode 102 is made of relaxed n-type polysilicon material, the upper electrode 104 is made of relaxed p-type polysilicon material, and the absorption region 103 is made of a single-layer relaxed intrinsic SiGeSn composite material, which is arranged alternately with the gaps to form a fin structure; The shape of the upper electrode 104 is the same as the fin shape of the absorption region 103 . The surface of the upper electrode 104 and part of the sides of the absorption region 103 are wrapped with a single-layer stress film 105, such as image 3 shown. The stress film generates stress in the absorption region 103 to realize band gap adjustment of the absorption region 103 and inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com