A Composite Insulator with Built-in Capacitive Equalizing Screen

A composite insulator, capacitor voltage equalization technology, applied in the direction of insulators, circuits, electrical components, etc., can solve the problems of electromagnetic environment insulation material performance influence, uneven surface electric field distribution, etc., to reduce corona phenomenon, improve electric field distribution, easy to use The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

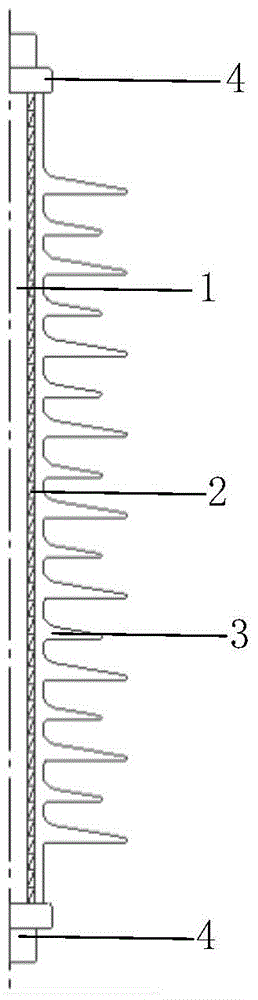

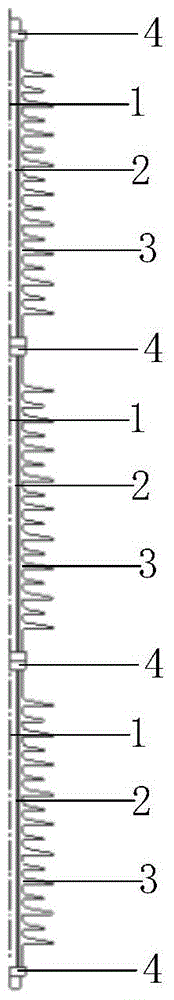

[0027] The composite insulator (hereinafter referred to as the insulator) with the built-in capacitance equalizing screen provided by the present invention has a structure as follows: figure 1 As shown, it includes a mandrel 1, a capacity equalizing screen 2 is provided outside the mandrel 1, a jacket 3 is set outside the capacitive equalizing screen 2, and fittings 4 are at both ends of the insulator.

[0028] The material of the mandrel 1 is epoxy resin and E glass fiber.

[0029] A capacitive equalizing screen 2 is added between the core rod 1 and the jacket 3 of the traditional rod-shaped composite insulator, which can well improve the electric field distribution on the surface of the insulator.

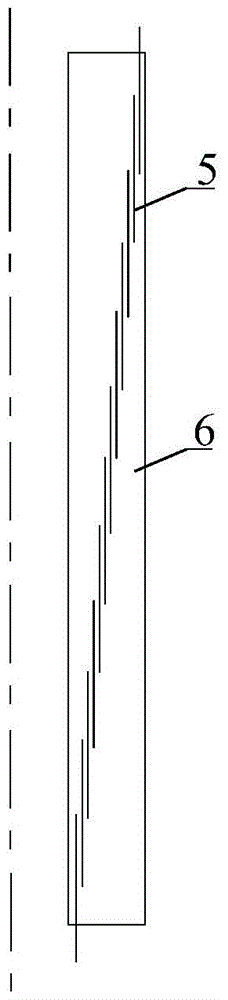

[0030] The structure of the capacitive equalizing screen 2 is as follows: image 3 As shown, the capacitance equalizing screen 2 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com