Wind turbine generator system low-wind-speed airfoil section family

A wind turbine, low wind speed technology, applied in wind turbine components, wind turbines, wind turbines that are consistent with the wind direction, etc., can solve the problems of lack of new airfoil design data and aerodynamic data, affecting blade design level, etc. Achieve stable and effective output power, good geometric compatibility, and small power and load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

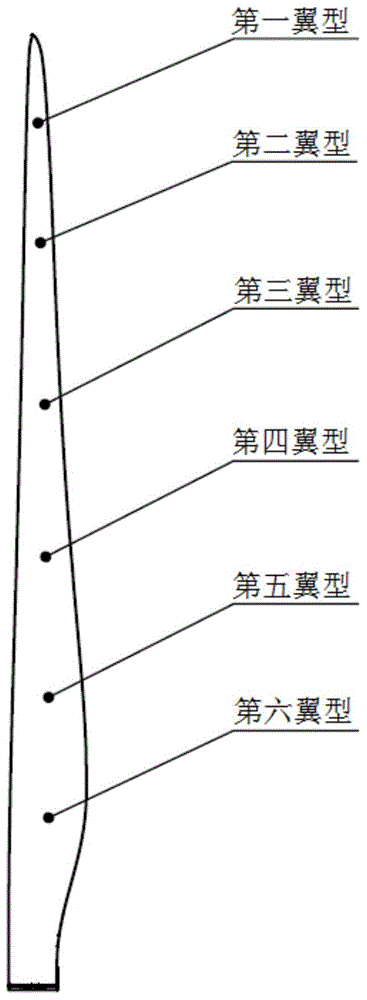

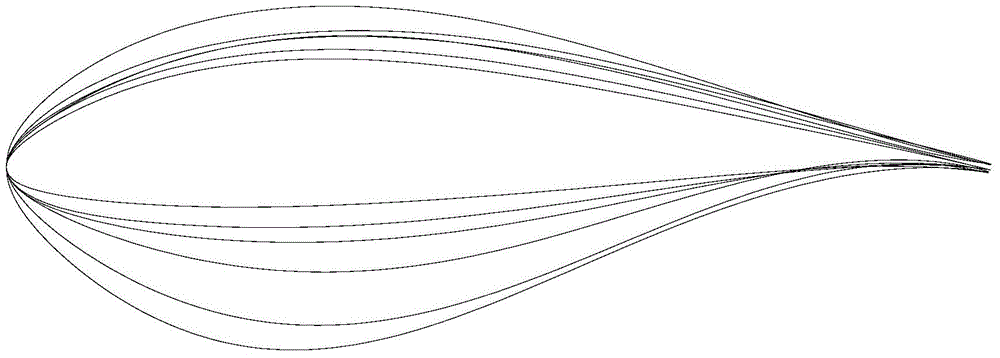

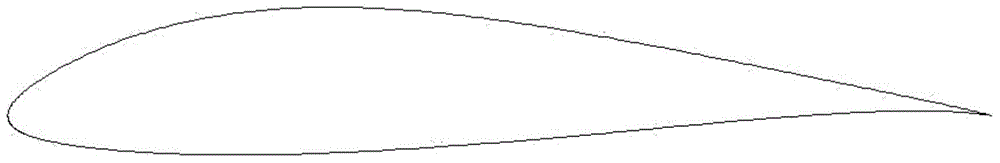

[0035] The present invention provides a low-wind-speed airfoil family of wind turbine blades. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036]The special airfoil family of the wind power generating set of the present invention is based on the XFOIL software for geometric design and aerodynamic calculation of the new airfoil. XFOIL was originally written by Dr. Mark Drela of the Massachusetts Institute of Technology in 1986. The calculation model uses a combination of viscous and inviscid methods, and is mainly used for the design and calculation of subsonic airfoils. Due to its fast calculation speed and good robustness, XFOIL is very suitable for dealing with low Reynolds number flow problems of wind turbines, and the accuracy of calculation results meets the design requirements, so it has been widely used in the field of wind turbine airfoil design.

[0037] The special airfoil family for w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com