Circumferential block structure of prefabricated rectangular shield tunnel lining

A technology of rectangular shield and block structure, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problem of no clear definition of segment segments, increased opening of segment joints, unfavorable tunnel stress and waterproofing, etc. problems, to achieve good resistance to external soil loads, improve tunnel stress and waterproof capacity, and ensure the effect of lining stress performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

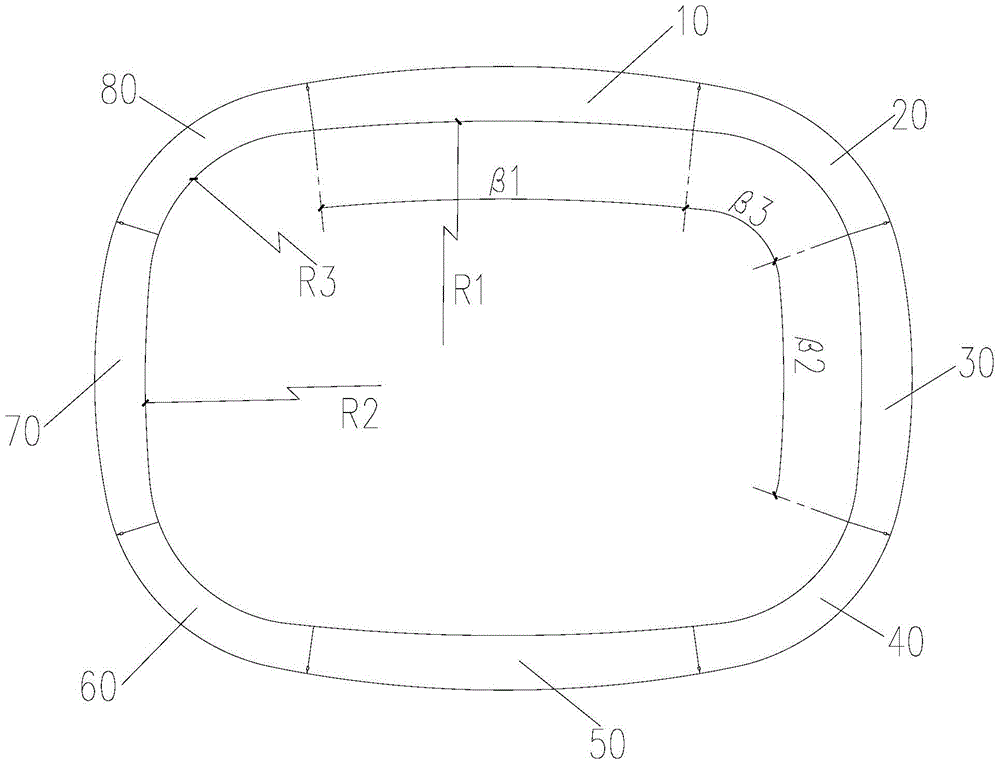

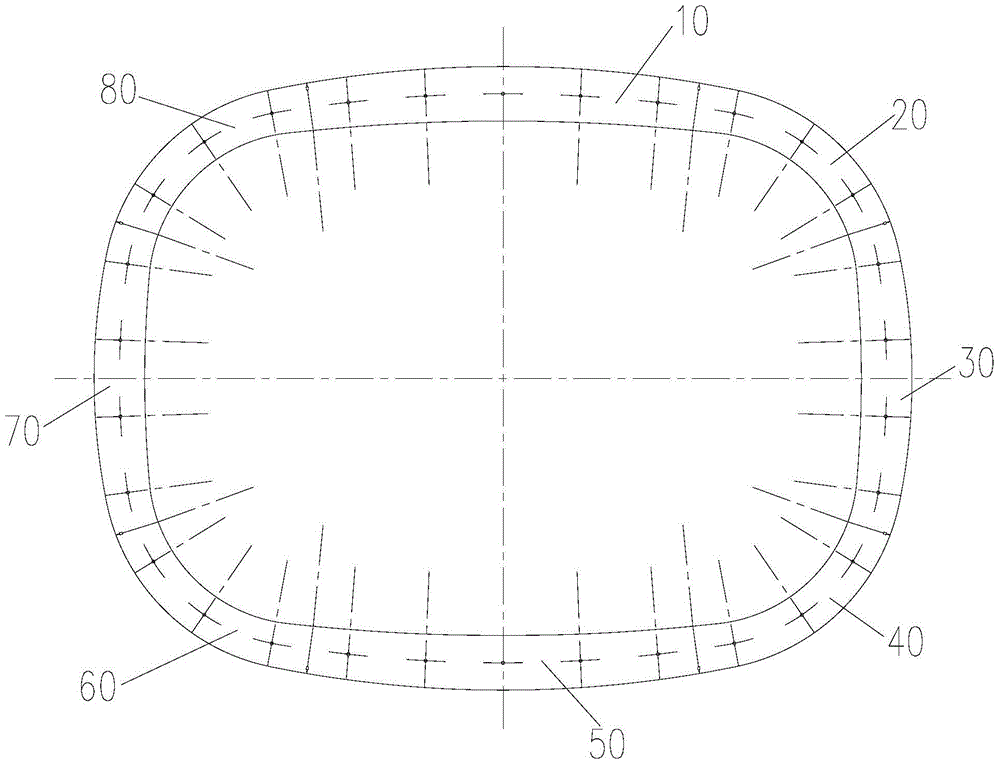

[0018] Such as figure 1 As shown, the ring block structure of a prefabricated rectangular shield tunnel lining in this embodiment consists of top inverted arch block 10, first corner block 20, first side wall block 30, The second corner block 40, the bottom inverted arch block 50, the third corner block 60, the second side wall block 70 and the fourth corner block 80 are connected in series, and the fourth corner block 80 is also separated from the top inverted arch. Blocks 10 are connected to form a closed circle as a whole, and the seams between adjacent blocks are located at places where the lining is less stressed.

[0019] The inner arc radius R1 of the top inverted arch block 10 and the bottom inverted arch block 50 of this embodiment is both 24000mm-26000mm, the angle β1 is 10°-12°, the first side wall block 30 and the second side wall The inner arc radius R2 of the wall block 70 is 14000mm-16000mm, the angle β2 is 38°-42°, the first corner block 20, the second corner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com