Large span steel tube arch bridge stents-free hoisting process

A steel pipe arch bridge and steel pipe support technology, which is applied to arch bridges, bridges, bridge forms, etc., to achieve the effects of reasonable design, convenient realization, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

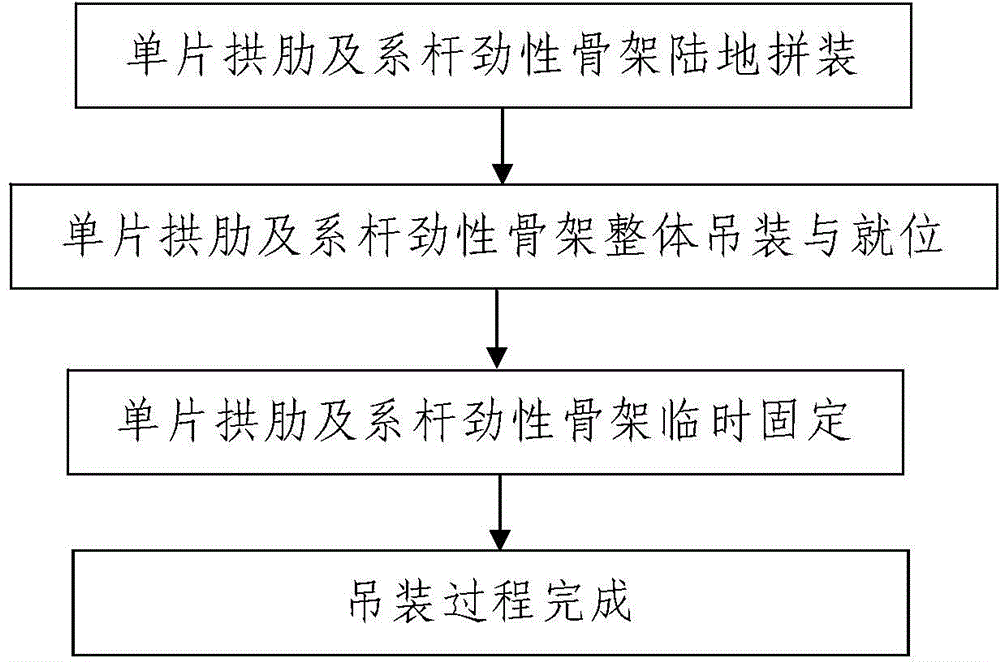

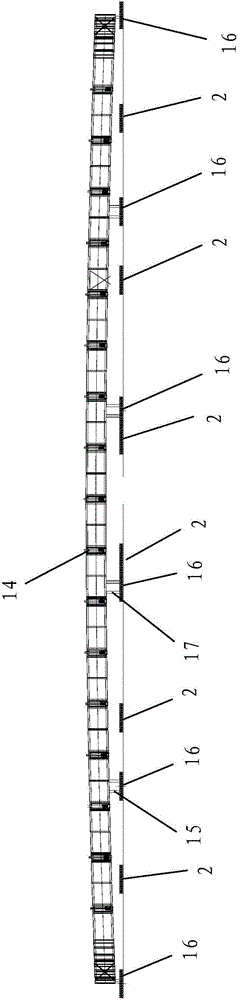

[0084] Such as Picture 1-1 The shown large-span steel pipe arch bridge has no support hoisting process, and the long-span steel pipe arch bridge constructed is a tie-bar arch bridge erected on the river 22, combined with figure 1 , figure 2 , image 3 and Figure 8 , the tied arch bridge includes a bridge lower support structure 23 and a bridge superstructure supported on the bridge lower support structure 23, and the bridge superstructure includes an arch rib 1 and a tie rod connected between the two arch feet of the arch rib 1 , the tie rod is located directly below the arch rib 1 and a stiff skeleton 14 is arranged inside it. The rigid frame 14 is a rigid frame that reinforces the tie rods and is assembled from a plurality of rods. Both ends of the rigid frame 14 are respectively fastened and connected to the two ends of the arch rib 1 . The arch rib 1 is a steel pipe concrete structure and it is composed of an arched steel pipe support and a concrete structure poured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com