Pile column type concrete hollow pile pier structure

A technology of concrete and hollow piles, which is applied in the field of bridge pier structures, can solve the problems of large steel consumption, difficult construction, and high construction costs, and achieve the effects of improving bearing capacity, saving construction period, and stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows: embodiment

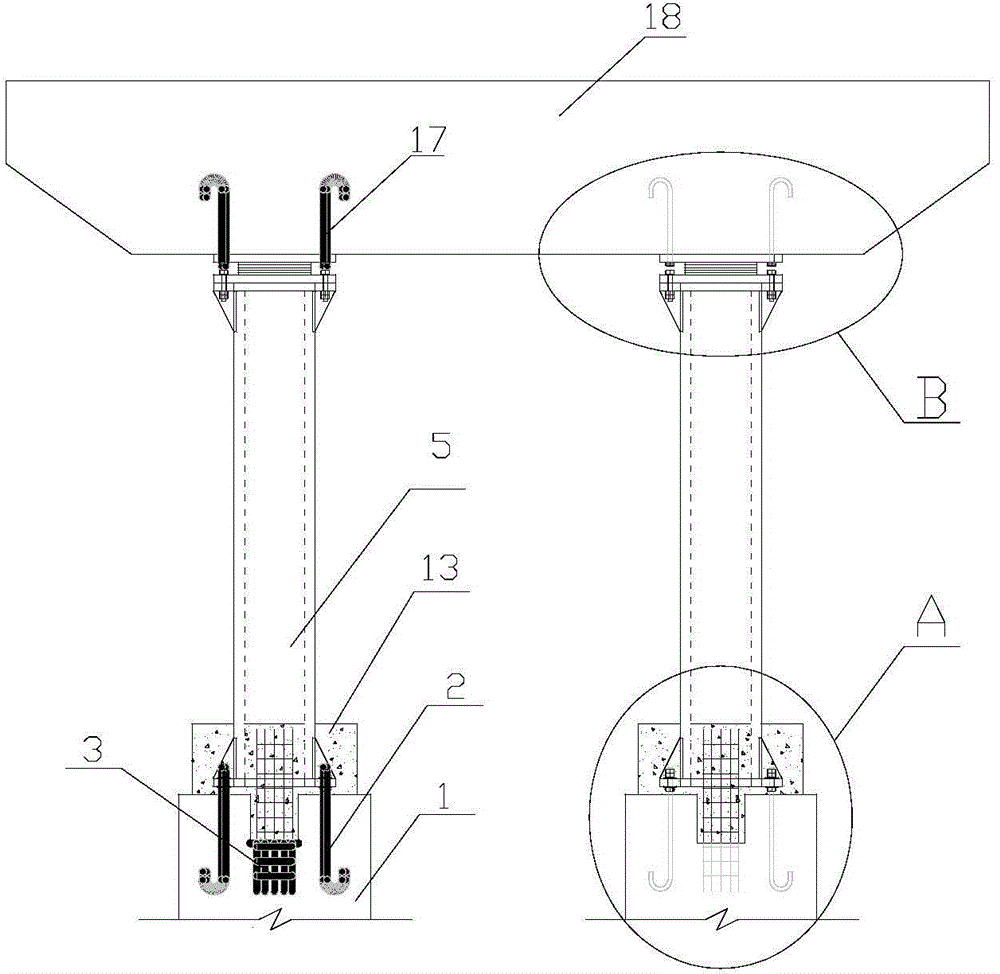

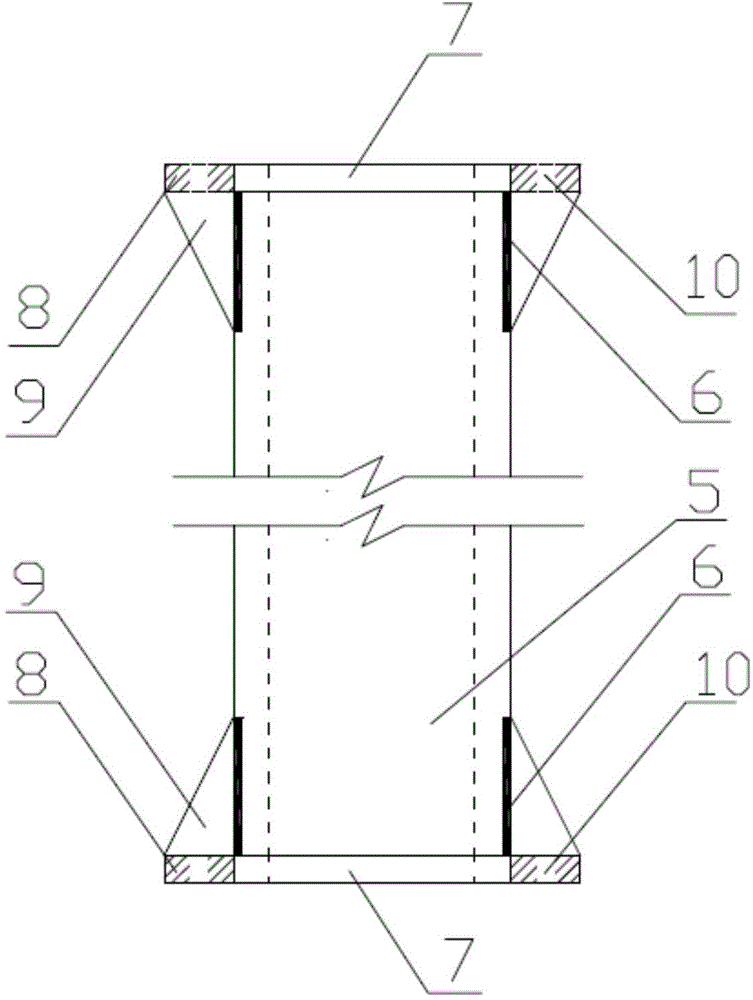

[0030] See accompanying drawing for details, compared with prior art, the present invention provides a kind of pile type concrete hollow pile bridge pier structure, comprises concrete hollow pile bridge pier 5, bridge bearing 15, bridge pier cover beam 18 and foundation cap 1, so The lower end of the concrete hollow pile pier is provided with a flange 8, and the flange is provided with a reserved bolt hole 10, and the flange is connected with the foundation cap, and the flange and the foundation cap are placed on the cast-in-place concrete In 13, the upper and lower surfaces of the bridge support are respectively provided with a steel plate 16 on the bridge support and a steel plate 14 under the bridge support. The steel plate is connected, and the steel plate on the bridge support is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com