Two-side front jacquard satin towel and weaving process thereof

A front jacquard satin file and towel technology, applied in the direction of excavation fabrics, textiles and papermaking, fabrics, etc., can solve the problems of pattern design, lack of layering, etc., and achieve rich and colorful expressions, multiple designs and creative spaces, three-dimensional strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

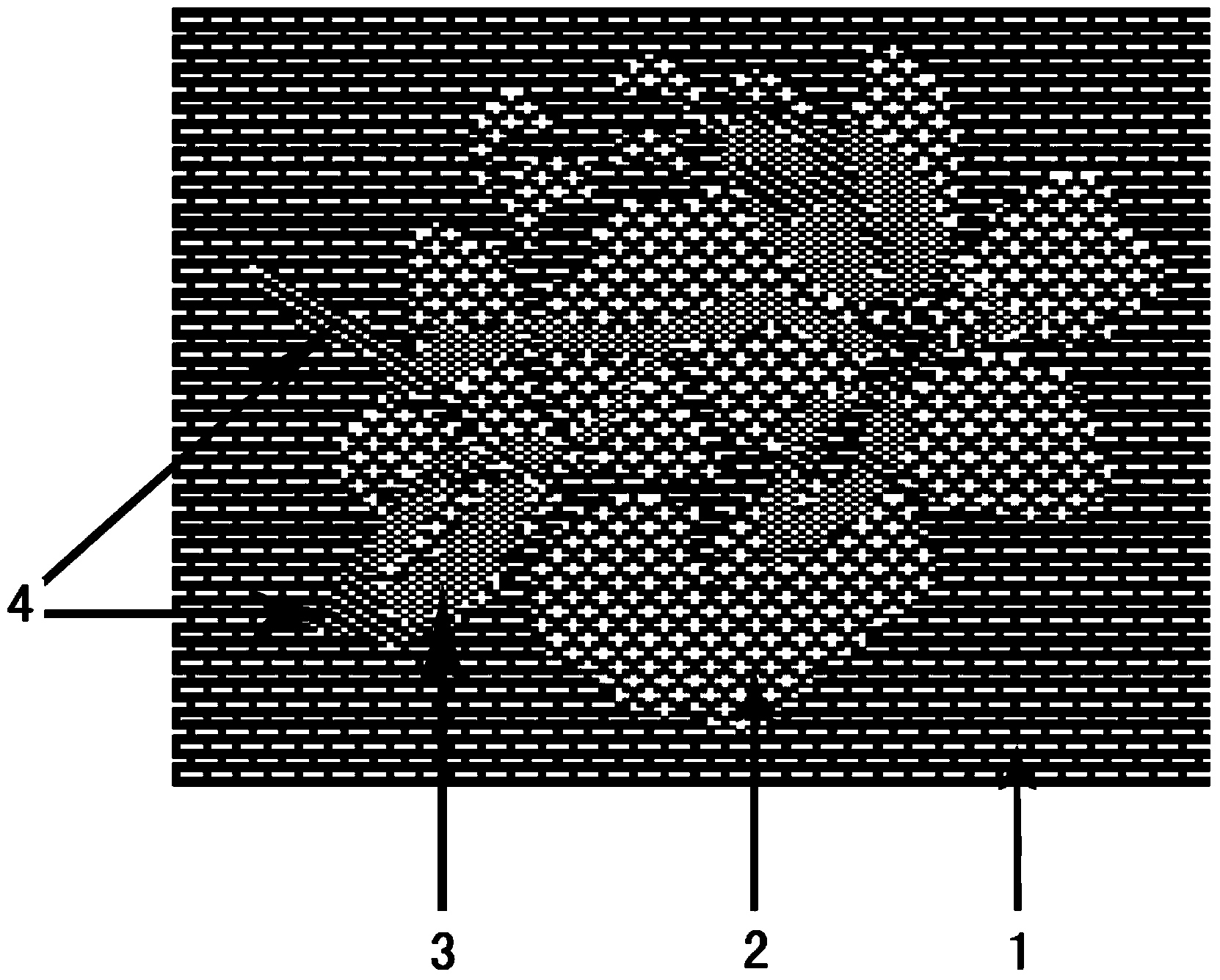

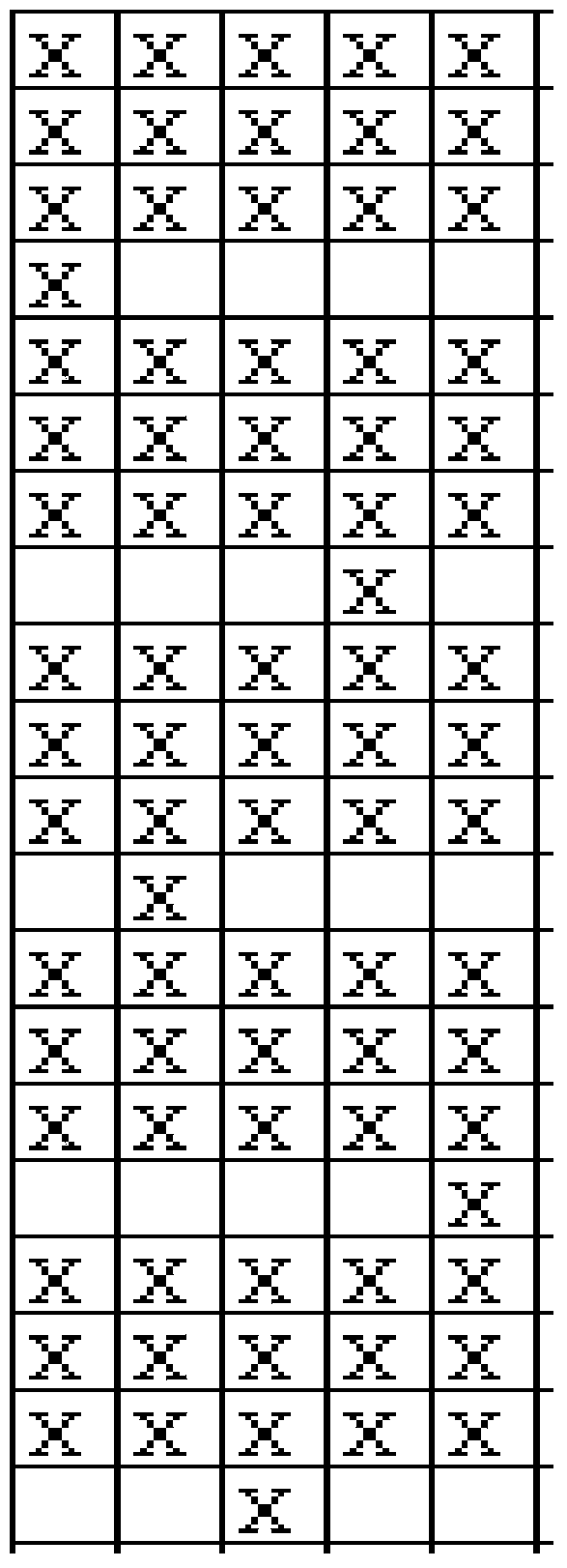

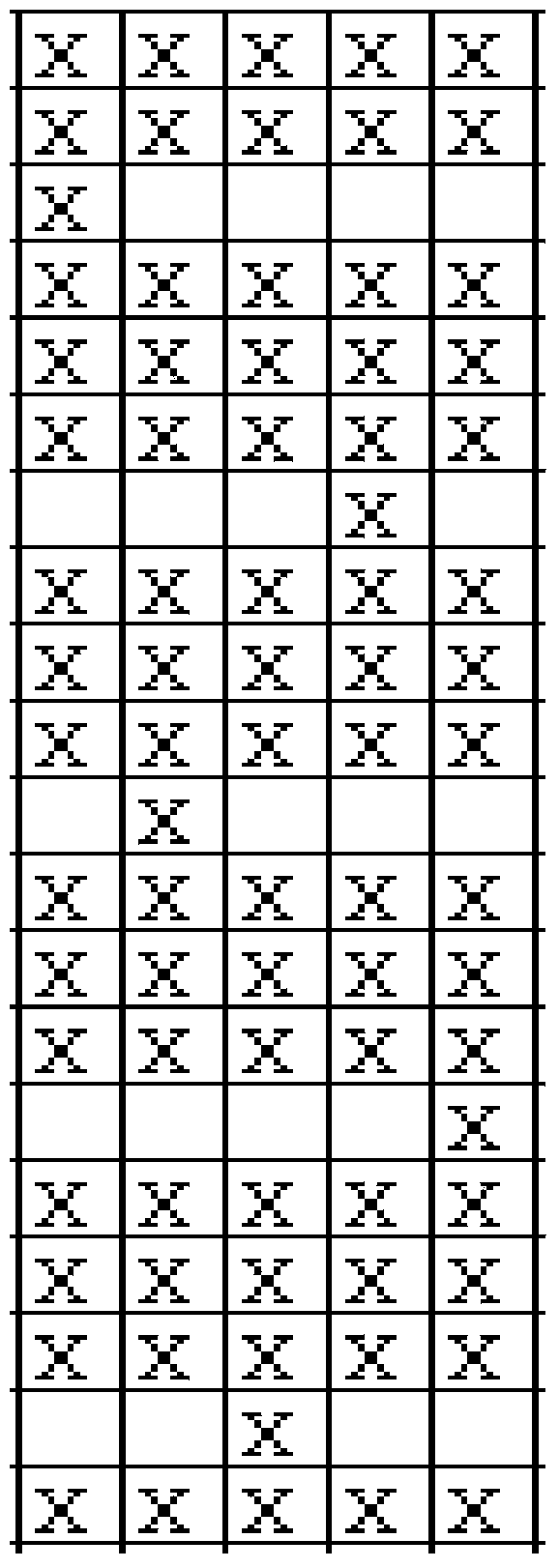

[0038] A double-sided front jacquard satin towel, woven from the ground warp, wool warp and weft yarn, the weft density is designed to be 85 threads / cm, the weft yarn count is 18.2tex×2 ply weft yarn, and the warp yarn is divided into four layers , wherein the ground warps of the upper two layers interweave with the weft yarns to form a front pattern, wherein the wool warps of the lower two layers interweave with the weft yarns to form a reverse pattern, and the gap between the front pattern and the reverse pattern A plurality of evenly distributed binding structures formed by pile warp and weft yarns are connected as a whole, the density of the binding structures is one binding structure per 10 wefts, and the binding structures are evenly distributed on the towel in a staggered manner.

Embodiment 2

[0040]A double-sided front jacquard satin towel, which is woven from the ground warp, wool warp and weft yarn. The weft yarn is 4-color beat-up, and the weft density is designed to be 82 pieces / cm. The weft yarn count is 29.2tex×2 ply weft yarn , the warp is divided into four layers, wherein the ground warps of the upper two layers are interwoven with the weft yarns to form a front pattern, and the wool warps of the lower two layers are interwoven with the weft yarns to form a reverse pattern. It is connected as a whole with a plurality of evenly distributed binding tissues formed by wool warp and weft yarns between the reverse pattern textures. The density of the binding tissues is one binding tissue for every 8 wefts, and the binding tissues are in the Stagger evenly over the towels.

Embodiment 3

[0042] On the G6300 rapier satin loom, the warp yarns are divided into four layers, the weft yarns are beat-up in 4 colors, the weft density of the weft yarns is designed to be 90 pcs / cm, and the weft yarns are 18.2tex×2 plied weft yarns, and the plied twist is 33 twists / 10 centimeters, interweave the ground warps of the upper two layers with the weft yarns of two colors to form a front pattern, and wherein the wool warps of the lower two layers are interwoven with the weft yarns of the other two colors to form the reverse side pattern, at the same time, a plurality of evenly distributed binding structures are formed by the warp and weft yarns, and the front pattern structure and the reverse pattern structure are connected as a whole, in order to ensure the flatness and better hand feeling of the product satin Softness, the density of the binding tissue is one binding tissue per 12 wefts, and the binding tissue is evenly distributed on the towel; in order to ensure the flatness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com