Stainless steel slag drying and winnowing device and its drying and winnowing method

A stainless steel and steel slag technology, applied in the field of air separation device and stainless steel slag drying, can solve the problems of difficult control of the water content of steel slag, inability to achieve air separation, and easy wear and tear of equipment, so as to reduce technical risks, reduce content and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

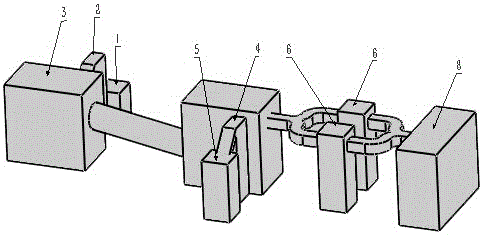

[0036] Such as figure 1 A stainless steel slag drying and winnowing device shown includes a hopper 1, the inlet of the hopper 1 is provided with a bar screen, the outlet of the hopper 1 is connected with the bottom end of the bucket elevator 2, and the bucket The top of the type hoist 2 is connected with the feed inlet of the drying kiln 3, the inside of the drying kiln 3 is provided with a lifting plate, and the drying kiln 3 is also provided with a combustion-supporting fan and a blower, and the blower is installed at the bottom of the drying kiln 3 On the side wall where the feed inlet is located, the blower is a variable frequency blower, and its blowing volume is determined according to the particle size of the powder to be screened; the bottom of the drying kiln 3 is provided with a pellet outlet, and the pellet outlet is connected to the pellet elevato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com