Solid washing-agent composition packaged by water-soluble membrane

A solid detergent and water-soluble film technology, applied in the field of daily chemical detergents, can solve the problems that detergent tablets are difficult to fully dissolve, limit the commercialization of detergent tablets, and conflict between the strength and dissolution rate of solid detergent tablets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

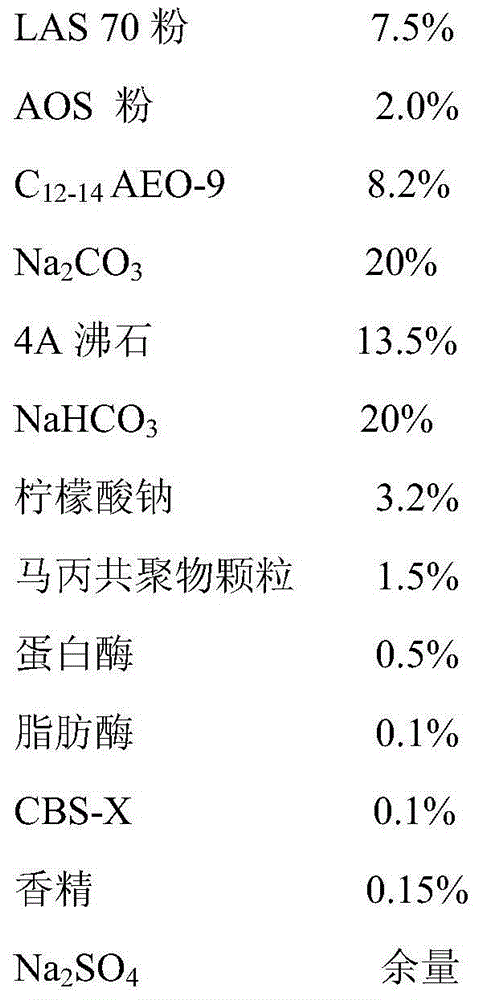

[0022] Add the following components in weight percentage to the double spiral cone mixer:

[0023]

[0024] Among them, non-ionic surfactant C 12-14 AEO-9 needs to melt into a transparent liquid before adding it. The above components are uniformly mixed by mechanical stirring, and the material is discharged to obtain a solid detergent. Using a film blowing machine, the vinyl alcohol / acrylamide copolymer with a degree of polymerization of 1800 and a degree of alcoholysis of 98.5% is made into a film with a thickness of 45um, and the solid detergent is processed on a vacuumed crawler groove packaging machine The package is made into a capsule-like water-soluble film solid detergent with a specification of 25g.

Embodiment 2

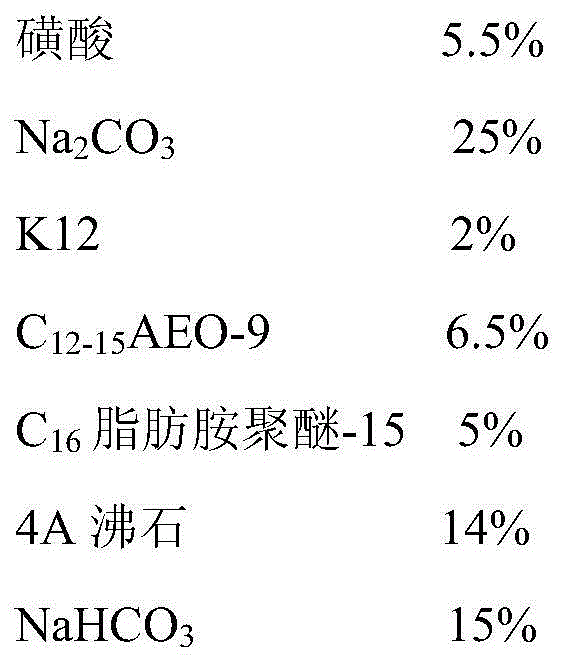

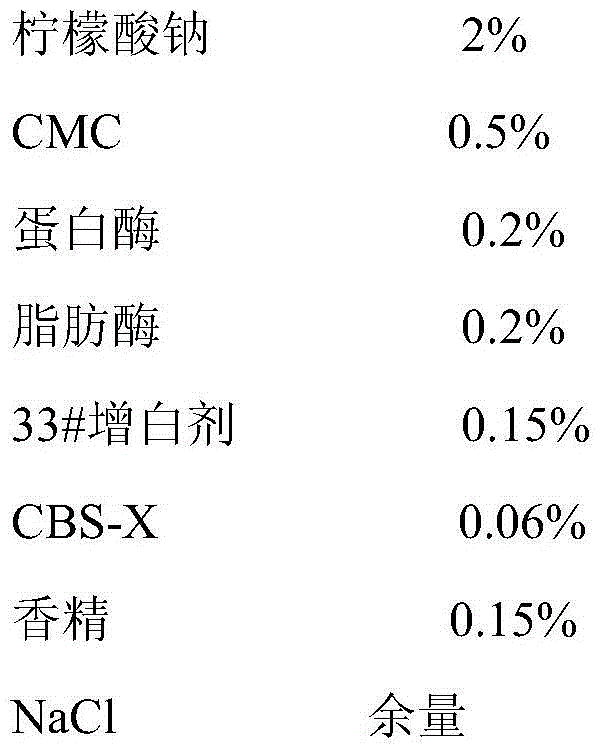

[0026] Add the following components in weight percentage to the double spiral cone mixer:

[0027]

[0028]

[0029] Among them, non-ionic surfactant C 12-15 AEO-9 needs to melt into a transparent liquid before adding it. The above components are uniformly mixed through mechanical stirring and discharged to obtain a solid detergent. Using a film blowing machine, the vinyl alcohol / acrylamide copolymer with a degree of polymerization of 1550 and a degree of alcoholysis of 98.8% is made into a film with a thickness of 45um, and the solid detergent is processed on a vacuumed crawler groove packaging machine The package is made into a 20g capsule-shaped water-soluble film solid detergent.

Embodiment 3

[0031] Add the following components in weight percentage to the double spiral cone mixer:

[0032]

[0033] Among them, non-ionic surfactant C 12-14 AEO-9 needs to melt into a transparent liquid before adding it. The above components are uniformly mixed by mechanical stirring, and the material is discharged to obtain a solid detergent. Using a film blowing machine, a vinyl alcohol / acrylic acid copolymer with a degree of polymerization of 1650 and a degree of alcoholysis of 99% is made into a film with a thickness of 45um, and the solid detergent is packaged on a vacuumized crawler groove packaging machine , Made into a 20g sac-shaped water-soluble membrane solid detergent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com