Gluing tape for SMT (surface mount technology) material strip connection and machining method thereof

A processing method and technology for sticking tapes, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of troublesome tape connection process, poor connection quality, affecting the processing efficiency of the assembly line, etc., and achieve the connection process. Simple, high connection quality, high connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

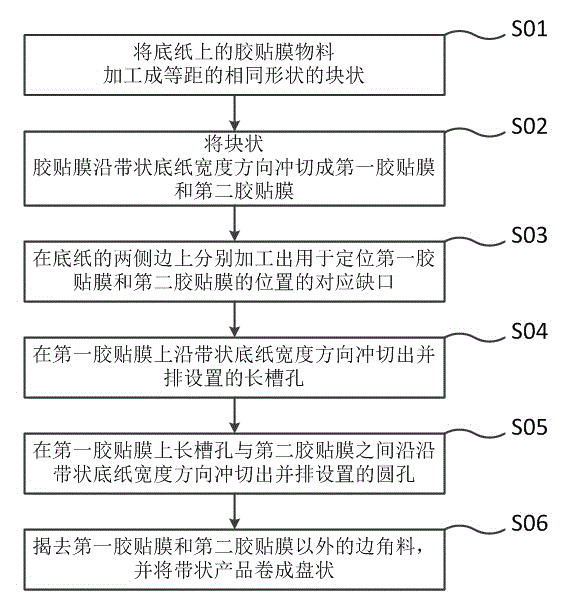

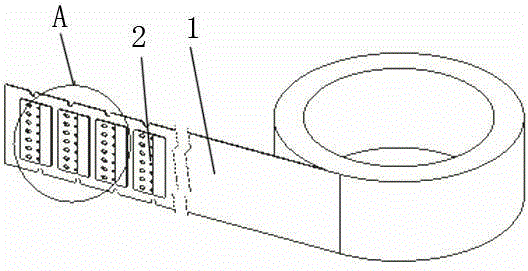

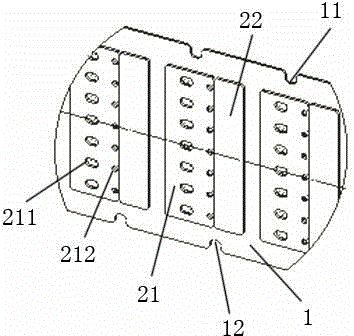

[0031] figure 1 It is a flow chart of the processing method in the present invention; it includes the following steps: step S01, the adhesive tape includes adhesive film material and strip-shaped bottom paper 1, and the adhesive film on the bottom paper is processed into equidistant blocks of the same shape Adhesive film 2;

[0032] Step S02, punching the block-shaped adhesive film into the first adhesive film 21 and the second adhesive film 22 along the width direction of the strip-shaped backing paper, wherein the first adhesive film is larger than the second adhesive film;

[0033] Step S03, processing corresponding notches for positioning the first adhesive film and the second adhesive film on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com