Low-VOC (volatile organic compound) polypropylene material as well as preparation method and application thereof

A polypropylene material and polypropylene technology, applied in the field of low acetaldehyde polypropylene material and its preparation, low VOC, modified polypropylene material, can solve problems such as no solution, and achieve the effect of reducing acetaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

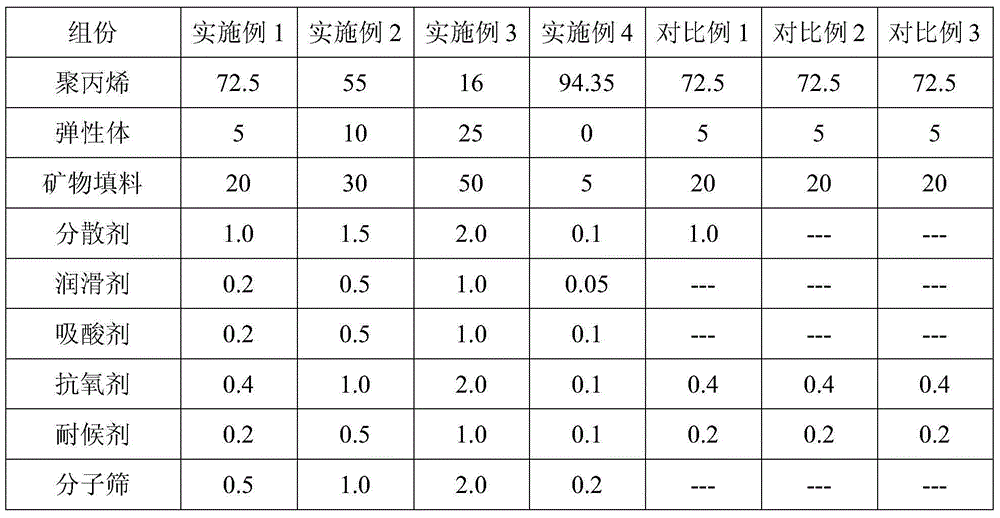

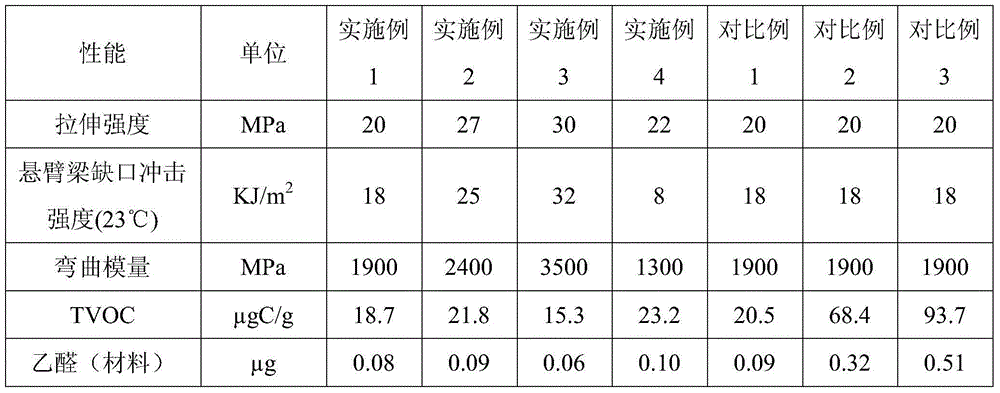

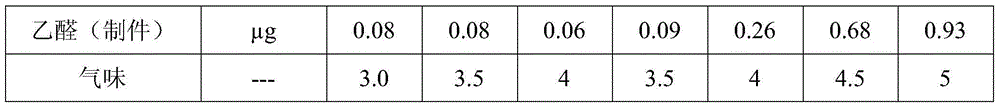

Embodiment 1

[0046] A kind of low-VOC polypropylene material, its raw material formula is shown in Table 1, and its preparation method comprises the following steps:

[0047] Add polypropylene, elastomer and dispersant to a low-speed mixer and mix evenly, with a rotation speed of ≤80r / min; then add mineral fillers, lubricants, acid absorbers, antioxidants, and weather-resistant agents for mixing, and finally add molecular sieves. After mixing evenly, add it from the main feeding port of the twin-screw extruder, carry out melt blending, vacuum extrude through the extruder, dry, granulate and classify with the granulator to obtain the low-VOC polypropylene material.

[0048] The aspect ratio of the twin-screw extruder is 48:1, and the temperature of the melting section of the twin-screw extruder is 180°C.

[0049] Among them, the polypropylene used is homopolypropylene, the elastomer is ethylene-butylene copolymer, the dispersant is acetone, the mineral filler is talcum powder, the lubricant...

Embodiment 2

[0051] A kind of low-VOC polypropylene material, its raw material formula is shown in Table 1, and its preparation method is with embodiment 1;

[0052] The aspect ratio of the twin-screw extruder is 48:1, and the temperature of the melting section of the twin-screw extruder is 210°C.

[0053] Among them, the polypropylene used is copolymerized polypropylene, the elastomer is ethylene-hexene copolymer, the dispersant is purified water, the mineral filler is talcum powder, the lubricant is C22 unsaturated aliphatic amide, and the acid absorber is stearic acid A compound of zinc and magnesium oxide in a mass ratio of 1:2, and the antioxidants are hindered phenolic antioxidants (antioxidant 3114) and phosphite antioxidants (antioxidant 168) at a ratio of 1:1 The mass ratio composition, the weather resistance agent is a hindered amine light stabilizer (Chimassorb 944); the molecular sieve is a hydrophobic zeolite molecular sieve with a pore size of 0.2-1 nanometer.

Embodiment 3

[0055] A kind of low-VOC polypropylene material, its raw material formula is shown in Table 1, and its preparation method is with embodiment 1;

[0056] The aspect ratio of the twin-screw extruder is 52:1, and the temperature of the melting section of the twin-screw extruder is 230°C.

[0057] Among them, the polypropylene used is homopolypropylene, the elastomer is ethylene-octene copolymer, the dispersant is a mixture of acetone and purified water at a mass ratio of 1:1, the mineral filler is talcum powder, and the lubricant is C25. Saturated aliphatic amide, the acid absorbing agent is a compound of zinc stearate and zinc oxide at a mass ratio of 1:3, the antioxidant is hindered phenolic antioxidant (antioxidant 1076), phosphite antioxidant The oxygen agent (antioxidant 626) is composed at a mass ratio of 1:1, and the weather resistance agent is a hindered amine light stabilizer (Tinuvin 770); the molecular sieve is a hydrophobic zeolite molecular sieve with a pore size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com