Technology for production of cyclohexanone by phenol hydrogenation

A production process, the technology of cyclohexanone, applied in the field of production process of cyclohexanone, can solve the problems of complex production technology of cyclohexanone, low catalyst utilization rate, low separation efficiency, etc., to avoid the loss of catalyst, operate Convenience and the effect of reducing recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

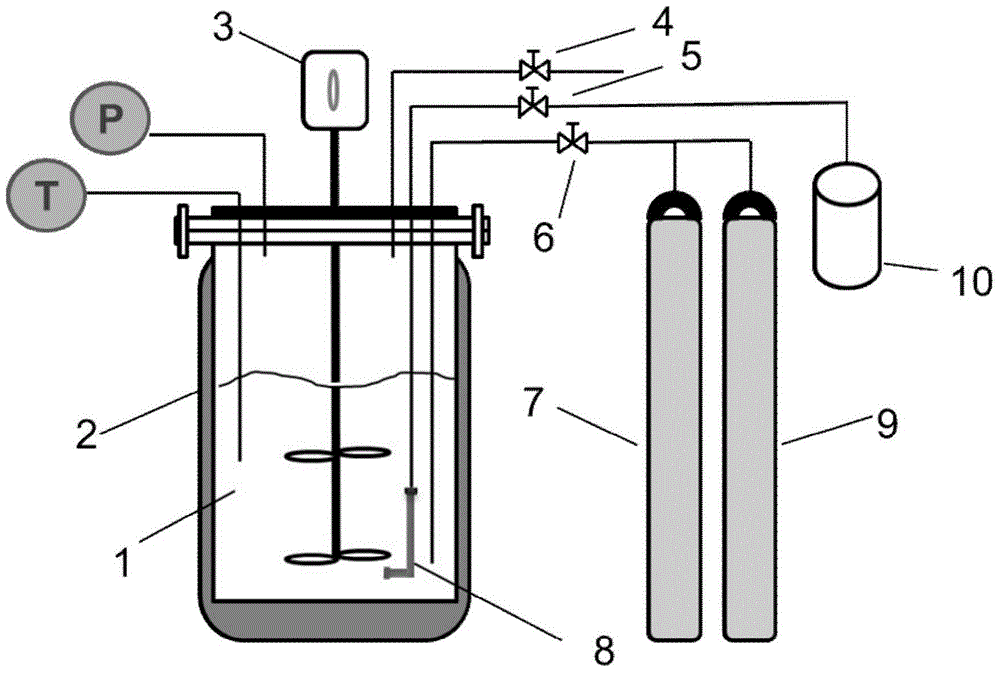

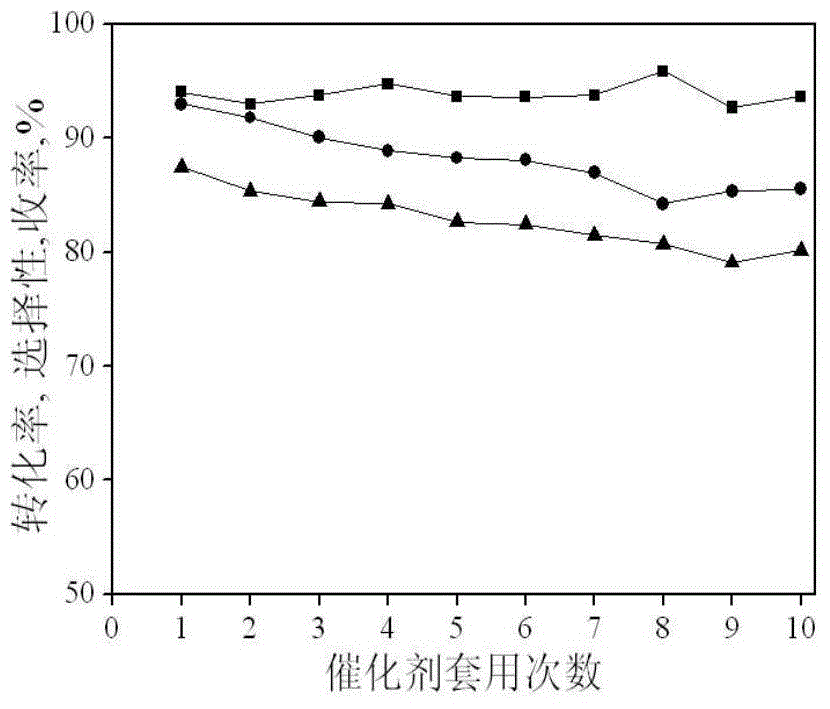

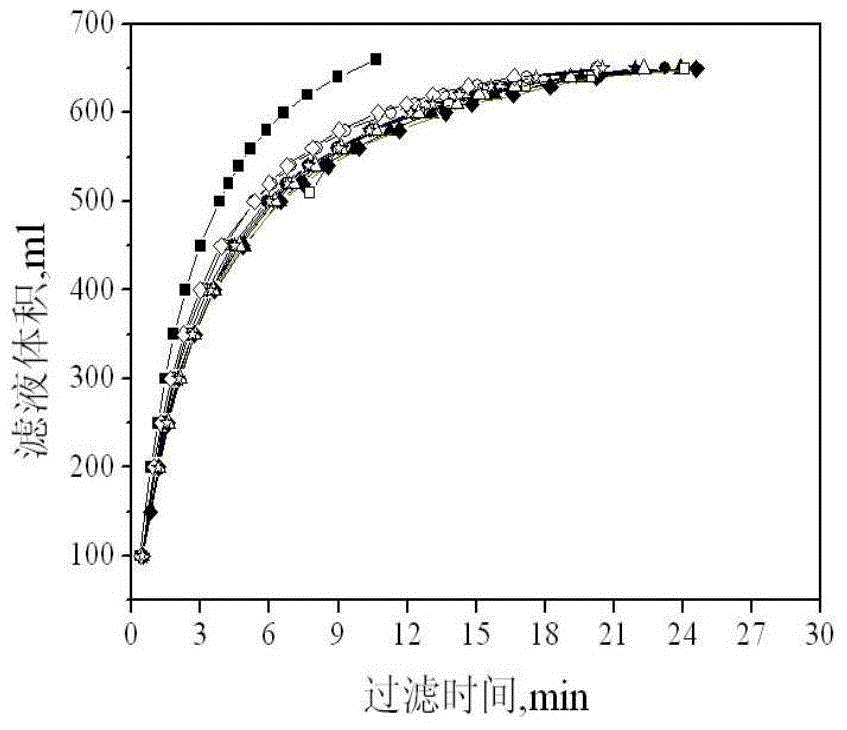

Embodiment 1

[0017] One end of the membrane is fired and sealed, and the other end is connected to the discharge pipeline with a rubber gasket and a stainless steel nut. Membrane tubes use 500nm pore size Al 2 o 3 Ceramic membrane tube, L-shaped membrane module. After the membrane was fixed, 8g of phenol (phenol concentration: 0.11mol / l), 750ml of deionized water, and 7.0g of PdCN catalyst (PdCN / phenol mass ratio: 7:8) were added to the reactor, and the total reaction volume was 765ml. After closing the kettle, exhaust 5 times at a hydrogen pressure of about 0.50MPa, turn on the stirring motor to 200r / min, heat to 80°C, adjust the hydrogen pressure to 0.50MPa, adjust the stirring rate to 500r / min, and start the intermittent reaction. During the reaction, hydrogen was supplemented to 0.50 MPa when the hydrogen pressure dropped from 0.50 MPa to 0.45 MPa. After reacting for 5 hours, discharge the unreacted hydrogen in the reactor, and replace it twice with nitrogen at 0.5 MPa. Cool down t...

Embodiment 2

[0019] One end of the membrane is fired and sealed, and the other end is connected to the discharge pipeline with a rubber gasket and a stainless steel nut. The membrane tube uses a zirconia membrane with a pore size of 500nm and a horizontal membrane module. After the membrane was fixed, 18g of phenol (phenol concentration: 0.25mol / l), 750ml of methanol, and 2g of PdCN catalyst (PdCN / phenol mass ratio: 1:9) were added to the reactor, and the total reaction volume was 763ml. After closing the kettle, exhaust 5 times at a hydrogen pressure of about 0.5MPa, turn on the stirring motor to 200r / min, heat to 90°C, adjust the hydrogen pressure to 1.0MPa, adjust the stirring rate to 400r / min, and start the intermittent reaction. During the reaction, hydrogen was supplemented to 1.0 MPa when the hydrogen pressure dropped from 1.0 MPa to 0.95 MPa. After reacting for 8 hours, discharge the unreacted hydrogen in the reactor, and replace it twice with nitrogen at 0.5 MPa. Cool down to 30...

Embodiment 3

[0021]One end of the membrane is fired and sealed, and the other end is connected to the discharge pipeline with a rubber gasket and a stainless steel nut. The membrane tube uses a stainless steel membrane tube with a pore size of 100nm and a vertical membrane module. After the membrane was fixed, 34g of phenol (phenol concentration: 0.48mol / l), 715ml of dichloromethane, and 6.8g of PdCN catalyst (PdCN / phenol mass ratio: 1:5) were added to the reactor, and the total reaction volume was 756ml. After closing the kettle, exhaust 5 times at a hydrogen pressure of about 0.5MPa, turn on the stirring motor to 200r / min, heat to 30°C, adjust the hydrogen pressure to 1.0MPa, adjust the stirring rate to 800r / min, and start the intermittent reaction. During the reaction, hydrogen was supplemented to 1.0 MPa when the hydrogen pressure dropped from 1.0 MPa to 0.95 MPa. After reacting for 8 hours, discharge the unreacted hydrogen in the reactor, and replace it twice with nitrogen at 0.5 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com