A large-scale honeycomb ceramic carrier shell mud formula with high hardness and good water resistance without burning

A honeycomb ceramic carrier and water-resistance technology, which is applied in the field of large-scale honeycomb ceramic carrier outer skin mud formulations, can solve the problems of non-burning outer skin mud peeling, roasting and cracking when exposed to water, and achieve enhanced water resistance, improved bonding force, and good waterproof effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

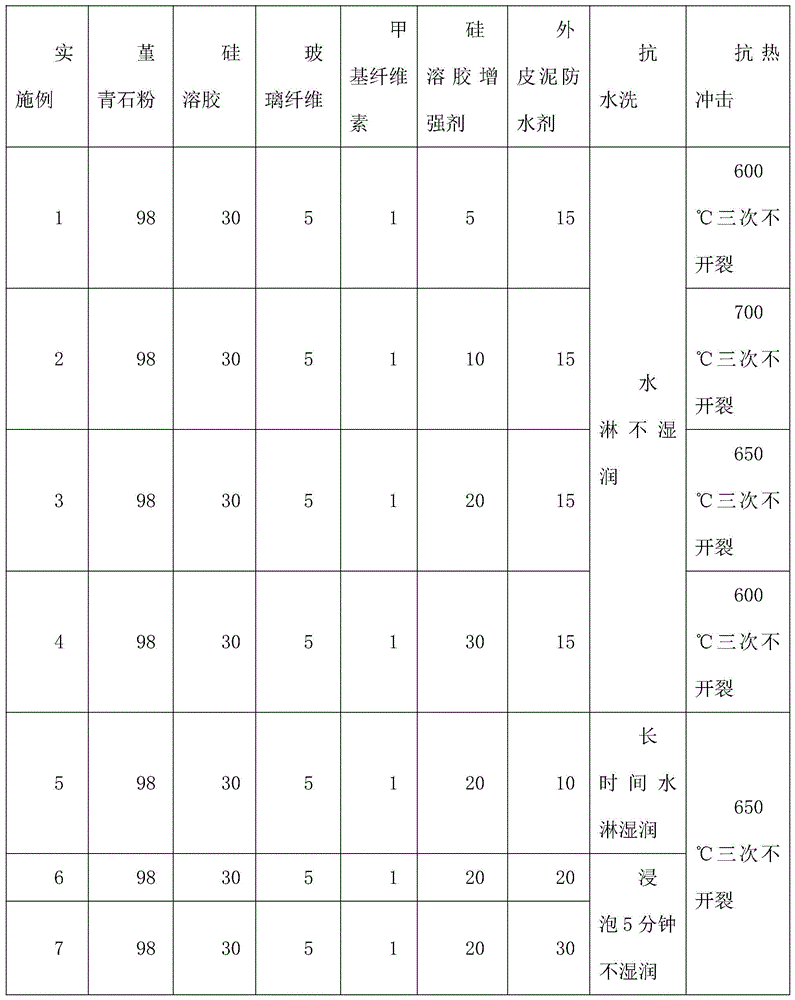

Embodiment 1

[0017] In the embodiment of the present invention, a large-scale honeycomb ceramic carrier shell mud formula with high hardness and good water resistance without burning, the raw materials include 98 parts by weight of cordierite powder, 30 parts of silica sol, 5 parts of glass fiber, methyl cellulose 1 part, 5 parts of silica sol reinforcing agent and 15 parts of skin mud waterproofing agent.

Embodiment 2

[0019] In the embodiment of the present invention, a large-scale honeycomb ceramic carrier shell mud formula with high hardness and good water resistance without burning, the raw materials include 98 parts by weight of cordierite powder, 30 parts of silica sol, 5 parts of glass fiber, methyl cellulose 1 part, 10 parts of silica sol reinforcing agent and 15 parts of skin mud waterproofing agent.

Embodiment 3

[0021] In the embodiment of the present invention, a large-scale honeycomb ceramic carrier shell mud formula with high hardness and good water resistance without burning, the raw materials include 98 parts by weight of cordierite powder, 30 parts of silica sol, 5 parts of glass fiber, methyl cellulose 1 part, 20 parts of silica sol reinforcing agent and 15 parts of skin mud waterproofing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com